Velocite is constantly pushing the envelope of design, releasing the 2nd generation of the RT50 wheel set. Aimed at being aero, but not just in a straight line, the design story on these is long and technical, with Velocite breaking out computer hardware and software not typically used in the cycling industry.

Velocite is constantly pushing the envelope of design, releasing the 2nd generation of the RT50 wheel set. Aimed at being aero, but not just in a straight line, the design story on these is long and technical, with Velocite breaking out computer hardware and software not typically used in the cycling industry.

They say the main objective in this redesign was to fine tune the handling of deep profile rims in crosswinds. The methods employed were cool to see, click through to get the scoop…

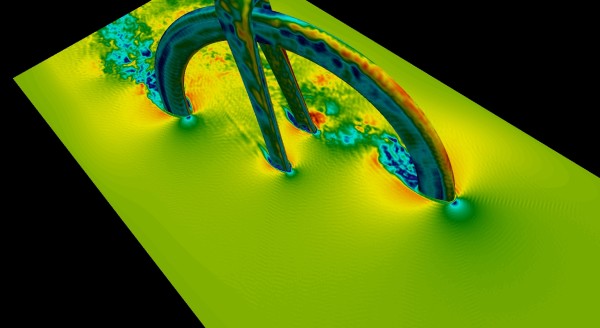

Computational Fluid Dynamics is a type of simulation software to simulate airflow over an object in the computer. Velocite says it is like a wind tunnel, except that using CFD allows the experimentation to happen before the product is created and designed. They say this creates better products because it designs the product for the flow of the air, where as a wind tunnel can only validate or verify something that is already designed. This software was created with the help of the University of Geneva in Switzerland. It is so complex, that less than 1 second of simulation results in an enormous volume of data, and they can see all airflow around the wheel when compiled and played back in slow motion.

A seamless brake track is another new feature that is integrated into the rim profile, and makes for a simpler and stronger layup of the rim. This is made with a special resin with a higher transformation point of 377º Fahrenheit, minimizing the chance of a brake track failure due to overheating.

The rim profile is a popular 25mm wide, but not for the same reasons as other makers. Velocite still strongly advises the use of a 23mm tire on the wider rim, because it completes the airfoil shape they used in simulations to maximize the aerodynamics. Using a wider tire would negate that effect and add weight, neither of which are their intent for this wheel set. The rim design is also for road tubeless tires, and a liquid sealant should be used.

The wheel set is completed with the Gram Triplet hubs that use a24-count, 2:1 rear spoke ratio, meaning twice as many spokes on the drive side of the rim. The front has 20 evenly distributed straight pull spokes.

In the video below, this is the data taken from the CFD analysis, stretched out to 7 seconds to highlight what can be seen. The full development story can be found here, and if you understand the technical bits, it’s very fascinating. Velocite’s RT50 is available now, direct from the company for $1,889 per pair. That includes spare spokes and nipples, brake pads and warranty card, and they come pre-taped and have tubeless valve stems installed.

In the video below, this is the data taken from the CFD analysis, stretched out to 7 seconds to highlight what can be seen. The full development story can be found here, and if you understand the technical bits, it’s very fascinating. Velocite’s RT50 is available now, direct from the company for $1,889 per pair. That includes spare spokes and nipples, brake pads and warranty card, and they come pre-taped and have tubeless valve stems installed.

Weight is 1,660g, which isn’t the lightest 50mm deep wheel we’ve seen, but you save 100g or so by not needing a tube. Plus, the decals are intentionally easy to remove, which’ll save a few grams and clean up the looks a bit.