Bikes shown at the North American Handbuilt Bicycle Show are objects worthy of drool. For years, I have seen the art that passes through those halls, and dreamt of someday owning one of these rolling masterpeices. The most impressive are the bikes that can hold their own for finish quality, yet you know are going to be ridden hard once the owner takes it from the show hall.

A few months back, we covered new builder Matter Cycles. After striking up a conversation with the owner, Collin, he mentioned that he would be showing his bikes at NAHBS this year. When writing the original story on them, I was very impressed with the BeneFat, Matter’s take on a fat bike. The 420mm chainstay length is the shortest I have seen on any fat bike, and I was looking for a trail-oriented fattie. A Surly Ice Cream Truck is a part of my stable for winter fat bike riding, but I wanted more of a dirt-oriented fat bike. You know, long, slack and low for ripping the trail.

Most NAHBS show bikes are actually owned by the builder’s customers. Most small builders don’t have the resources to build show-specific bikes, and they work with their customers to show off some of their best work. In this series, we will be following the entire process of building a Matter BeneFat, custom for me, and crafted as a show peice for the show. Here’s how it starts…

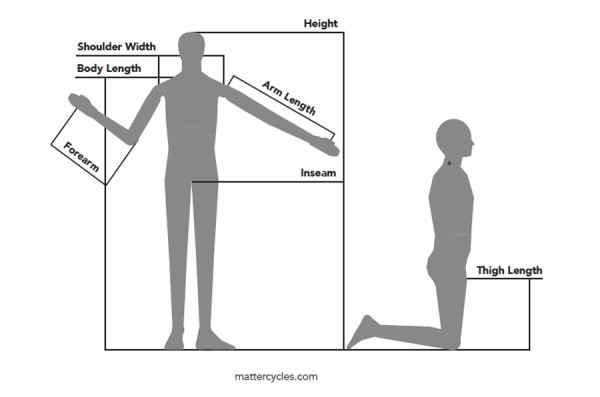

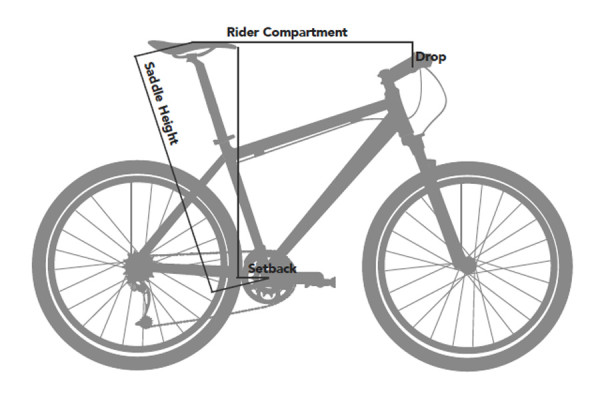

To start the process of building a custom bike for his customers, Collin Schaafsma starts with a form and an interview. We spoke on the phone for about a half hour, going through my riding style, current bike setup, likes and dislikes of that bike, points of discomfort and what worked well for me. He also sends out a form that thoroughly takes my personal information, but also has you record the details of your body and your bicycle.

When going through this part of the process, I knew that I was comfortable on my bike, but I didn’t know if it was correct. About a decade ago, I had been doing bike fittings for customers, but yet I had never had one done myself. At this point, I thought that if we were going to go through this much effort to make the perfect bicycle, it was worth a bit more to get a professional fitting, so we tabled the body fit discussion for a bit.

The bike I had in the back of my mind through this whole discussion was Matt’s Inglis. Shown at NAHBS back around 2010, I remember being impressed by it before I had ever met the owner. The bike has gone through a bit of a parts transformation over time, because Matt rides it, and rides it often. The picture above was taken by Zach last summer when it was updated with Whisky’s No.9 carbon fat bike rims.

This was the bike, beautiful but shreddable. However, there have been some advances in parts technology, so Collin and I talked through the next part of the process. We talked about how the bike would be used, and the functions I wanted out of it. I had a vision of a trail-oriented fat bike, where the primary purpose was riding on dirt in rough terrain, not beaches or snow like most fat bikes. In simple terms, I wanted a Kona Honzo as a fat bike.

To start with, my bike would be designed around the Rockshox Bluto. This single advancement has changed where fat bikes are used in tremendous ways, almost to a point where I cannot ride a fat bike without one now. Second, I was attracted to the short chainstays of the bike, so a it would be designed around a 1×11 drivetrain, making it easiest to tuck in that rear tire. Finally, I think dropper seatposts will change how we ride to the extent that clipless pedals did 30 years ago, so the bike had to have internal cable routing for a dropper post.

This series will be documenting the entire process of building a bike for NAHBS, from concept to show, and then riding it after. Check in next week as we go through the process of a bike fitting session to insure this bike will fit perfectly.