Now, we start to dig into tools. Probably the most needed item in your home workshop, and the most common first purchase, a good set of common tools are needed for about 75% of your bike repairs. There are a lot of starter kits out there which might work for your needs. Or you can create your own kit from the suggestions here.

There are a lot of great tool companies such as Park, Pedros, Lezyne, Birzman, plus some lesser known ones like Lifu, IceToolz and Spin Doctor. And tools don’t have to come from a bicycle-specific maker. There are also tools that are worth buying the top-end right away such as the Park professional chain tool above, and some where the basic tool works just fine.

Both Zach and I have been professional mechanics in the past, but do all of our work at home now. Take a look inside as we discuss what works for us in building the starter tool kit for your home workshop….

TIM: Park Tool may be the most popular of the bicycle-specific tool makers, since they probably have the most robust selection of bike tools, and have been around for a long time. They offer two great kits to start out, With the Home Mechanic Starter Kit on the left and the Advanced Mechanic Kit (also called AK-38). Going back 15 years, I had a job in a shop that required that I have my own tools, and the Park AK-32 was the first real bike tools I had. Things have changed over the years, so the kit changed name and now contains 38 peices, and is the least expensive kit that contains the shop-grade cable cutters, chainwhip, chain tool and pedal wrench. Even at 15 years old, all my original tools may show wear, but are still fully functional. So if you can afford the $330, it is the best place to start.

Zach: The AK-32 was my first set of real bike tools as well. When I was 12 I decided I needed to pull apart the hub on my Kona Lavadome after riding into a lake… that’s a normal thing to do right? Only I didn’t have any idea what I was doing and managed to pull off the freehub without taking off the cassette first. After a trip to the local bike shop and a few days without riding I vowed to learn how to do all my own repairs and eventually was given the AK-32 as an awesome gift from my parents. Like you, all of those tools are still in use except for the chain cleaner which broke.

Tyler: I’m almost embarrassed to admit my first all-in-one was the Nashbar kit that came in a plastic case with molded shapes for the basics. It was cheap and it did the job for many years, though, even back when adjusting threaded headsets was a common repair.

I think we will all vouch for the Park kits at this point, but these days there are a number of other great options out there as well. I keep the Shimano PRO tool kit in my car at all times for trail size fixes. Due to the blow molded case which keeps everything neat and tidy, it has a low profile that is great for road trips and keeping your OCD at bay. This would also be a great option for starting a home shop. If you want the organization of the PRO kit with even more tools, we were impressed with Birzman’s Studio kit at Frostbike last year.

TIM: I find the best way to assemble a really good home tool kit is to find out what the shop guys are using. When you go to purchase your tools, ask them for their recommendation. That is how I once found the Pedros Pro Socket Handle, and even though I am biased towards Park, the Pedros is by far the best way to hold a cassette lockring socket. For a starter kit, you will need a chainwhip and a lockring socket in order to remove the cassette, but you can hold the socket with an adjustable wrench as well.

Zach:I’ll second the Pedro’s Pro Socket handle over the Park equivalent, but when it comes to cassette tools for me nothing beats a Crombie tool from Abbey Bike Tools. One piece, nothing to lose, the Crombie fits Shimano and Campy lockrings, and in most cases doesn’t require you to remove the skewer. In some instances having the center pin does help, but I haven’t come across anything yet where I couldn’t use the Crombie. I’m less particular when it comes to chainwhips, but Park’s professional model has always been a favorite. For someone building up their tool arsenal, something like Lezyne’s Classic Chain Rod makes sense since it also includes a lock ring wrench.

TIM: A pretty important piece that is typically left out of starter kits is a hammer. Available from most home improvement stores, there are a few that you may want, as a standard hammer may do damage to more fragile bike parts. One I always have around is a dead-blow hammer. This is a hammer made with a rubber or plastic face, and filled with free-moving weights inside. This allows you to stike something without the rebound of a metal hammer, as it transfers all of the kinetic energy instantly. They are able to do this by having some space inside where the filler weight, typically lead shot or sand, provides inertia, but dampens the shock. A dead-blow hammer is a helpful tool for tapping lightly on crank spindles or steerer tubes of modern bikes, where tight tolerances make them a bit stiff to remove. The other one I always have around is a brass headed hammer. Brass is softer than steel, but is very heavy, so it’s a great hammer to have around if you really need to coax out a stuck item, but the softer brass won’t deform or break things. Both of these are not bicycle-specific, and are available anywhere.

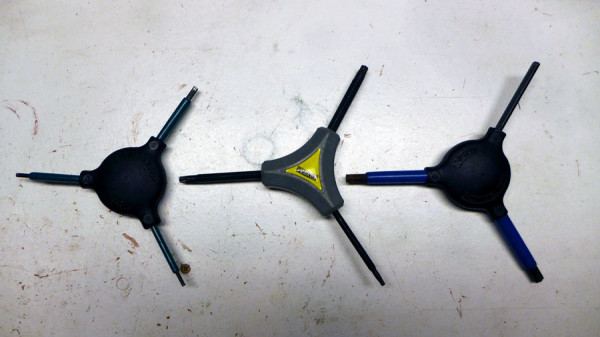

TIM: This is a debate between mechanics that will likely never be settled, to use Y-wrenches or long-handled wrenches for your primary allens. A Y-wrench gives you three sizes in your hands at all time, but may not be ergonomically perfect, and lack on the ability to generate real torque. Long-handled allens give you plenty of leverage, and are easy to hold, but really slow down the work process, as each time you need a new size, you need to put down one tool, and grab another. I have strong hands, so I really prefer Y-wrenches. Pedros has a nice one out now that has the three commonly used Torx sizes on it, T10, T25 and T30.

Zach: Sorry Tim, but my motto has always been 3-ways do not belong in the workshop. Period. I keep one in the door pocket of my car for quick adjustments trailside, but you will never find a 3 way on my work bench. In most cases I find the three way design to interfere in tight quarters and doesn’t offer the perfect balance of a T-wrench for quickly spinning fasteners. I don’t like most P-handle wrenches either, since they can be ungainly and really only useful in certain circumstances that require a ball end. Either Allen or Bondhus T-wrenches along with a Bondhus (Park) L-Wrench set is exactly what you’ll find on my bench.

Tyler: I’ve always stuck with the Pedros “L” hex wrench set, which is available under a number of different brands but offers a 1.5/2/2.5/3/4/5/6/8/10 all in a convenient holder. This has lasted me more than a decade of continuous use, so I’d qualify this under the one-and-done category of buy a good one first so it lasts. The handles are longer than what you find on cheaper kits and most hardware store purchases, too, which provides more leverage.

Tim: Agreed. Even if you are a Y-wrench person like me, someday you will need the extra leverage for a stuck bolt, or need to access a place the Y-wrench won’t fit into. Bondhus heads allow you to still turn the bolt, even if the wrench is accessing from an angle, thanks to a really cool semi-rounded head.

Zach: Yeah, the Bondhus wrenches are a sure thing. Bondhus manufactures many of the Park Professional L-Shaped wrenches so you could buy these in red or blue.

Tyler: Lately, though, much of my work has been done with either the Fixit Sticks shop model T-handle or the Prestacycle Presta Ratchet, both shown here:

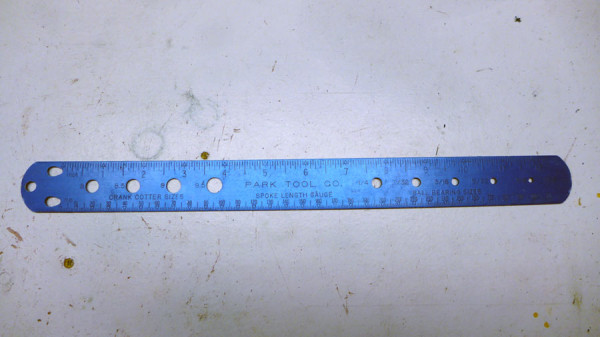

TIM: This great Park metric ruler came as a feature in my original AK-32, but is no longer in the AK-38. It was able to measure ball bearing sizes, and spoke lengths, two things that are slowly going away with sealed cartridge bearing and proprietary-spoked system wheels. Whatever you use, make sure your kit has a metric measuring device. Even though we are in the last bastion of the English System of Measurement, the bicycle industry operates in the metric system, and almost all hardware and specifications on your bike will be in metric.

Zach: I’m sad to hear the Park ruler is no longer in the set, definitely a great piece. The only reason I ever reach for a different ruler around the shop is to use the DT-Swiss ruler which has built in spoke gauge measurements.

TIM: Here are a few more tools to add, whether you buy a pre-made kit, or make your own, since these are not included in kits. Also, even though you have cable cutters, you should NEVER use those to cut zip-ties or other packaging. A set of side cutters and end cutters are also available from hardware stores, and using them will help save your cable cutters for only what they were designed for. Vice-Grips are another must, even for a small tool kit, as they can help you grab a stuck item, or even a wrench if you need a third hand for a certain task.

Zach: A quality set of side and end cutters are definitely important, don’t skip here. I went through 3 cheap side cutters at the shop in the same time frame as a single pair from ChannelLock that are still going strong.

Tyler: I’d add a simple tape measure to the list, too. I use mine constantly for checking seat height on the various bikes that come in. And I’m always letting friends borrow bikes, so it’s great to be able to get them right back to my preferred spot. If you have a professional bike fit done, it’s always good to double check all the measurements whenever switching out a saddle, stem, etc. Chances are you’ve already got one laying around the house, it’s just time to move it to your new workshop.

LIST OF NEEDED TOOLS –

- Metric Allen Wrenches – Y-wrenches if you like that sort of thing, and a long-handled L wrenches

- Chain tool – Don’t skimp on this, its important, and cheap ones are hard to use and break fast

- Chain whip and cassette tool (unless this is beyond your ability, then take it to a shop for this)

- Screwdrivers

- Cone wrenches (unless this is beyond your ability, or your bike does not use adjustable bearings)

- Spoke wrench(es)

- Pedal wrench

- Metric open-end wrenches for 6mm-10mm

- Cable Cutters – this is another place to get the best you can afford.

- Vice Grips

- Tire levers and patch kit

- Side cutters and end cutters

- Metric measuring device

- Hammers

- Tape measure

Check back in for Part 4, where we start to dive into the big and technical tools that you may need to perform the more difficult jobs.

If you haven’t seen them already, make to check out all of the other installments from our Home Workshop Series!