Slava Menn is a serial entrepreneur and CEO of Fortified Bicycle. He loves biking, building, entrepreneuring, and teaching. In this monthly series, he shares his team’s hard-learned startup lessons with aspiring entrepreneurs.

Our first articles showed you how to ease a pain with a product idea and how to go from idea to prototype. Assuming you’ve proven the concept viable and have a working prototype, it’s time to hit “go”on the production line and manufacture en masse, right? Not so fast – you first have to slay the meanest, nastiest dragon in the startup world: volume manufacturing.

We’ll get into price negotiation, quality control, and supply chain optimization later, but first we must learn to source an honest, quality manufacturing partner to take you from prototype to thousands of products.

Step 1: Educate yourself

Look around: you’re surrounded by volume-manufactured products. But, if you’re like me, you have no idea how any of it–the pen on your desk, the mug you’re drinking from – is actually made. Before we dropped $50K on our first manufacturing order, I had to educate myself about how bike lights are made so that I could talk shop.

I didn’t need to be a manufacturing guru, I just needed enough knowledge to ask technical questions and know when to call BS. When I stood on a Shenzhen manufacturing floor with a group of die-cast engineers and asked, “Is a two millimeter wall-thickness possible to cast?” I didn’t care about the answer. I wanted to show that I wasn’t ignorant – because if you’re ignorant, they can take advantage of you.

Step 2: Try “Made In America” Before Looking Overseas

There are countless social, economic, environmental, and even marketing benefits of “Made in America” local manufacturing (assuming you’re in America). In contrast, the only reason to manufacture overseas is cost.

Editor’s note: Another reason can be finding the right expertise. Many major bike brands have told us that Taiwanese carbon frame manufacturing is among the best in the world, especially when you need it done on a large scale. Obviously you need to do your research and find a reliable partner. The quality from one supplier to the next can be night and day. It’s also highly recommended you have your own employee or independent rep on sight to manage it and make sure you’re getting what you specified before a container load shows up. So, depending on what type of product you’re looking to make and the anticipated volume, overseas manufacturing might make sense for more reasons than just cost. – Tyler

Because overseas labor is dramatically cheaper, your Bill of Materials (BOM) is typically lower. But looking at BOM cost alone is shortsighted. What really matters is Total Cost of Ownership (TCO).

Overseas manufacturers cost more time –both in man hours and months of production time- because of communication barriers. TCO incorporates this as well as travel costs and the opportunity cost for shipping a product later.

When you manufacture locally, you’re a short trip away from your manufacturer and you’re speaking the same language. This makes it substantially faster and easier to dial in quality products, all of which can lower your TCO.

In the case of our lights, we tried to manufacture locally, but our substantial labor and assembly requirements made that economically unfeasible. Making them in the U.S. would force us to sell our bike lights for an unaffordable $200 instead of $50.

Step 3: Hunt For A Contract Manufacturer Like Your (Startup’s) Life Depends On It

Because your startup’s life does depend on it!

>The key here is to cast a wide net to capture as many leads as possible. You can read about how we messed this up last year when searching for a manufacturing partner for our Aviator/Afterburner bike light. In short, we started with a long list of 12 manufacturing leads. After a few months of weeding out the dregs and negotiating with the four who remained, we ended up with a grand total of….zero.

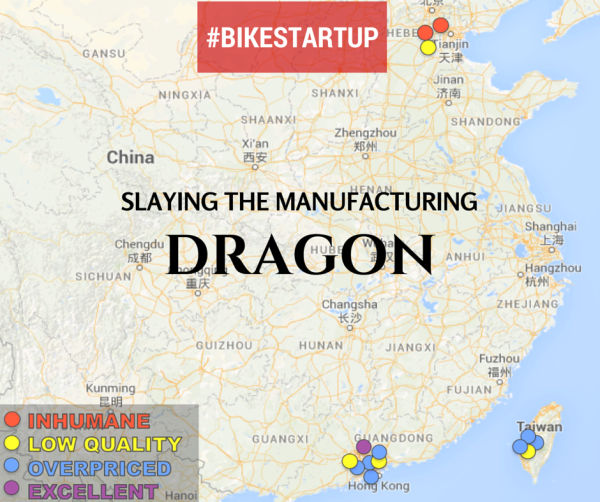

Recognizing our error, we went on a spree, calling everyone we knew in the hardware space and asking for intros to everyone they knew. This time our long list was 30, which became a short list of 14. I visited all 14 and found some were incompetent while others were inhumane polluters. Ultimately, we found one high-quality, fair-priced supplier with excellent working conditions.

In future issues of #bikestartup we’ll talk about what to do once you select a contract manufacturer and how to pay for production. In the meantime, ask us questions. We’ll answer every single one of them.