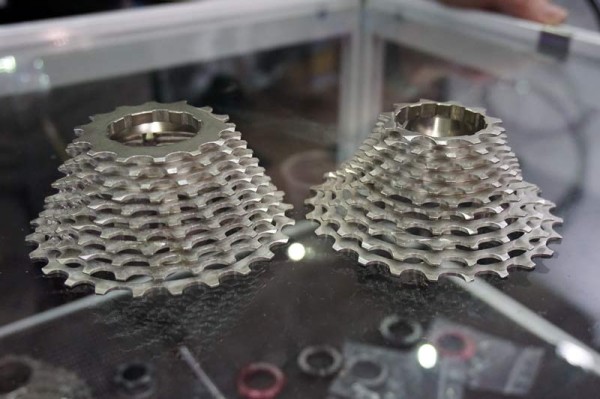

Edco has been machining their Monoblock cassettes from a single piece of hardened chromoly steel for a while, but the designs have been limited to standard road gearing ranges. Now, two new options push the gear selection in either direction, from a very narrow range model to a two-piece wide range mountain bike cassette.

The new narrow range Monoblock cassettes for junior racers, shown above left, are because the youngsters can’t run anything smaller than a 14-tooth cog per UCI rules. So, they make a 14-25 and 14-27 cassette, both with 11 speeds, that gives young racers tighter gaps between gears without having to restrict derailleur movement to keep them off the smaller cogs. Expect them to be about $200 USD. Like the others, it’s machined out of solid chromoly steel. Also like the others, it’s an 11-speed unit that’ll fit on a 10-speed freehub body, making it easy to put an older set of wheels to good use. Weight is about 200g.

Shift past the break for more details, plus a look at prototype carbon rims and more…

The deeper groove section under the smaller cog allows enough interface on the freehub body that the cassette can overlap it a bit to make room for 11 gears on a standard 10-speed freehub body. More details on that here.

Prototype mountain bike cassette is also 11-speed, and also fits on a 10-speed freehub.

It’s actually a dual block design, which was necessary because the size of the largest cogs would require too much machining to carve it out of a single block of metal. Weight is about 262g for the 11-40, and they’re working on an 11-42 also.

Edco also makes their own hubs in house, and the Aptera sets the flanges very wide to improve bracing angle.

For now, they’ve purchased Reynolds carbon rims in raw form, without spoke holes, then run them through their own 7-axis milling machine to align the holes perfectly for their own hubs.

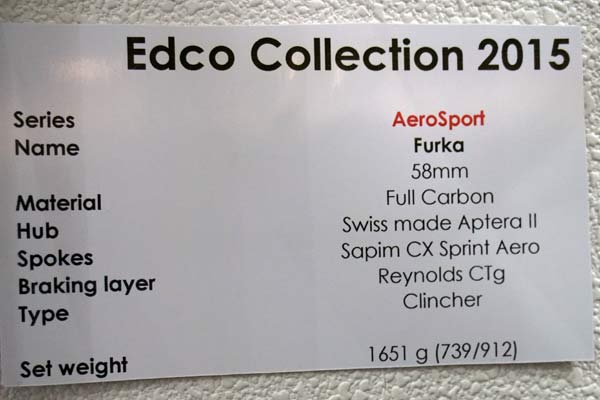

Above, the Aerosport series uses Reynolds’ AERO rims. If you’re wondering, that weight is about 70g heavier than Reynolds’ AERO 58 wheelset claimed weight, but the EDCO version uses more spokes.

The Albis Prosport wheel is coming for Eurobike and is the first time they’ve used their own molds to create the rim. It uses a woven carbon and HITG resin to keep heat in check on the brake track. It’ll run through the 7-axis milling machine to drill the brake holes also, and the rear gets their Aptera hub. This is as close as they’d let us get to it with the camera.