So far, our World’s Funnest Bike project has detailed the frame and the cockpit. Now it’s time to go over all the parts that make it go and make it stop. Most of the parts used on this project bike were new, but I did have some trusted components and lightly used parts that needed more time before a final review could be posted, so those made there way on board and will be noted.

The shifting is handled by Gevenalle’s latest GX shifter levers, which were designed around the Shimano XT rear derailleur to offer a wider range option for anyone wanting a more capable gravel/adventure/cyclocross bike. The Gevenalle parts were all weighed in with a full introduction in this post, so here we’ll go over their performance and use notes and show how it all came together with a mix of other components…

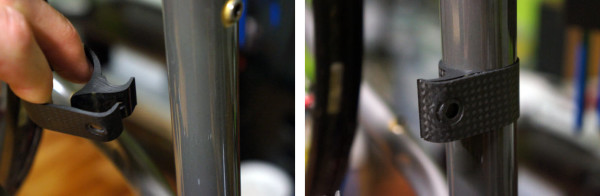

Gevenalle’s component line includes a front derailleur, too, and anytime I need to add such an appliance to my bike, Parlee’s carbon fiber front derailleur clamp is at the top of the list. At just 8g, it adds virtually nothing to the weigh of the bike.

It comes with a bolt and washer, which bring the total weight to 11g if you use those rather than the ones that come with the front derailleur. You simply spread it to snap around the seat tube, then install the mech. They recently revamped the design to make it stiffer to handle the additional forces applied by Di2 and EPS electronic front derailleurs.

Behold, and if I still need to explain why I chose this one, then it’s not worth explaining. The only arguments against it are that a) your local shop is highly unlikely to stock it, and b) it retails for $95. But look at it.

Adam from Gevenalle was kind enough to send a new XT rear derailleur and cassette so that we were testing it with equally fresh parts. Weights are 232g and 335g.

Put it all together and it looks just like a standard mountain bike group from the rear.

The Gevenalle BURD front derailleur debuted in August 2014 and is an upgraded Microshift part. The metal arms replace Microshift’s carbon piece and a few other tweaks were made to improve it’s strength and durability. It’s designed specifically for the smaller gear range of cyclocross…

…and it’s put to work moving the chain between FSA’s 46/36 cyclocross chainrings. The rings and the SL-K carbon crankset were both parts I had on hand, and it’s held in place with a SRAM pressfit BB. I used these because a) they were handy, but more importantly because b) they’re light, stiff and good looking. I had them on my ‘cross bike previously both with these rings and with the Absolute Black narrow-wide ring, but never cared for the red “K” on the graphics messing up my otherwise carefully curated color scheme. Here, it fits right in.

UPDATE: One important fit issue was with the size of chainrings that could be used. I tried putting a standard road chainring combo on and the rings hit the chainstay yoke. This bike needs smaller chainrings, and a ‘cross combo seems to be the right mix…unless a 1x is used.

The Crank Brothers Candy pedals were chosen partly because I like them, partly because I have them in for review and partly because the red matches the graphic hits on the frame (along with the bar tape and wheels). So far I’ve used this pair for all-mountain trail riding, cyclocross and now this bike and they’ve held up just fine. The cleats, per usual, tend to wear quicker than most, but the pedals have been solid and provide just enough platform to support mountain bike shoes that aren’t XC race stiff.

Likewise with the Cobalt 3 wheels, which have seen some use but not enough to justify a full review yet. So, as the color scheme started coming together, it was a no brainer. For all the knocks Crank Brothers gets as a design-first company, these wheels have been very solid so far.

At almost exactly 1,800g for the 29er wheelset (weighed with thru axles, but QR endcaps are used on this build), they’re not ultralight, but they don’t feel heavy on the bike. Most of the weight is closer to the hub thanks to their paired, two-piece spoke design.

The rims are closed completely, so the added weight and hassle of rim tape is unnecessary. They setup tubeless fairly easily. Check out the full tech run down on this latest generation of wheels here, then look for the full review from us later on.

To them I mounted a set of WTB NanoRaptor 29×2.1 mountain bike tires. These have a thin, closely spaced center tread row that rolls smoothly on pavement. This was my main consideration since I wanted to build the bike with proper 29er tires to see where all I could take it, but didn’t want a loud road buzz and constant vibration from traditional knobbies. On that front, they’re the perfect tire, working well on road and off and everything in between.

Where I’m having trouble is with toe overlap, and that’ll eventually force me to switch to a proper gravel tire. The versatility will suffer, but it’ll be lighter and faster and I won’t keep rubbing my toes on the tire when making slow, sharp turns. If toe overlap weren’t an issue, I’d keep the bigger tires on here all the time because it seriously makes for a wicked fun bike. I’ll be testing a few different options to see how big I tire I can get away with, and should you build up something like this, too, I highly recommend seeing what your local shop has in stock and mounting a few things up to see what works. Bigger is better for a bike like this, IMO.

Back to the shifters. When they first came in, I honestly wasn’t sure if I’d like them. Nick’s tested them and liked them, but the idea of reaching out in front and “regressing” to friction shifting on the front seemed like a step backwards. Fortunately, I was wrong. In an age of battery powered auto-trim and trim-free YAW front derailleurs, there’s still something innately satisfying about being able to fine tune the cage’s position from the command center, and Gevenalle’s shifters let you do just that.

Initially, the front derailleur’s spring would pull back downward a bit after shifting to the large ring, which led to a bit of unavoidable chain rub inside its cage on the lower end of the cassette. But, after tightening the allen bolt on the face of the shifter, it held tight and all worked perfectly. Did I say perfectly? Yes. Yes, I did. Fast, crisp shifts up front with manual trim…a thing of beauty.

Rear shifting was equally precise and has required zero adjustments since initial setup. The indexing is spot on, and the effort is minimal, just enough to prevent miss shifts. Rob is also testing a set of the originals with their own rear derailleur and has noted that during ‘cross racing, the more extreme nature of grappling with controls can lead to the occasional unintended shift when grabbing the brakes in a fit, but it’s rare and otherwise he’s pretty stoked on them, too. He’s running it as a 1x and will report in a separate review about the disassembly process to convert the left lever to a brake-only setup.

Speaking of brakes, the levers are TRP, which are mated to the 2nd generation TRP HyRD mech-to-hydro calipers. My first experience with these was good but a little underwhelming when paired with SRAM levers. I tinkered with them against the recommendations of TRP, so these are a welcome improvement. Right now, though, it’s apples to oranges comparison since they’re being used with different levers, but the performance is very good. They feel within 90% of a full hydraulic line, which is saying a lot compared to a full mechanical disc brake setup.

The HyRD brakes are a rather large part, but so far I’ve seen them fit on any frame with chainstay-mounted brakes. I did run into one fitment issue on the WTF, though:

With the adapter for a 140mm rotor, the edge of the brake’s mounting hole hit the frame and just barely made it so the bolt wouldn’t run straight into the adapter. So, I was forced to bump up to a 160mm rotor in the rear.

The rest of the fitment story revolves around the cable housing and brake hose/housing runs. Everything runs from the handlebar to the bottom of the downtube, held in place with clamshell mounts. It may not seem obvious at first glance, but there are top and bottom halves (identical, BTW) that sandwich the housing between them in neatly ordered lines. After the last one on the bottom, the brake hose splits off and runs atop the chainstay…

While the rear derailleur runs underneath the opposite chainstay. The derailleur housing runs a pretty direct line to the first chainstay clamp, which means it sits very close to these larger tires.

The machined chainstay yoke offers ample clearance, so I’ll be getting creative with zip ties to keep that cable housing out of the way. On a couple occasions I’ve heard the tire rub it when cornering or sprinting. Of course, smaller tires will help, too, but from a design standpoint I’d prefer to see standard cable guides on the stays that allow you to zip tie the housing into place. The clamps are very functional on the downtube, but more traditional guides would be better from the BB back.

The tire clearance at the top of the chainstays will never be an issue, there’s tons more space there than at the chainstays. On the fork, I’m pushing the limits and probably violating EN safety regulations with this tire. But a 42mm gravel tire should be perfect. I haven’t had any issues with the tire rubbing the fork, but there’s always the possibility a rock or stick could jam in there as is.

And that’s the bike. First impressions are really good. Everything is playing nicely together and it’s an absolute blast to ride. The swoop lines of the WTF draw plenty of “nice bike!” comments along the bike lanes. Most importantly, it’s just sheer joy to ride it. I’ll probably sub in VP’s R62 pedals for much of my summer riding. They blend a grippy flat surface on one side with SPD clips on the other, so I can clip in for a real ride in the morning then run to the grocery store in my flip flops in the afternoon without having to swap pedals. I’ve been using them on my ‘cross bike for just that and they’re perfect.

It’ll see plenty of miles this summer, with a long term review planned after the fall trade shows. If there’s a part, spec or build question, leave it in the comments and I’ll fill in the holes there (NOTE: Might be next week before all questions/comments can be addressed. I’m at Sea Otter all this week and it’s all consuming!).