Having apprenticed under Paul Sadoff for years at Rock Lobster and gotten his formal building education at UBI with Albert Eisentraut as his instructor, Jeremy SyCip got his start with a heck of a frame building pedigree. In recently downsizing his operation from a massive space in bustling downtown Santa Rosa to his home garage, Jeremy SyCip has embraced efficiency with fewer machines, less time in commute, and less time walking across the factory floor between building operations. I spoke with him about getting his start and some of his more recent projects in this shop at the SyCip Family Compound near Annandale State Park…

BIKERUMOR: You have clients come out here?

JEREMY: Yes. Now I do. Eventually I’ll have a little showroom downtown again. This is where I build all the bikes. I had to get rid of a few big machines when I moved out.

BIKERUMOR: How many bikes are you putting out?

JEREMY: I don’t even know… I probably average 2-3 frames a week.

BIKERUMOR: That’s pretty fast.

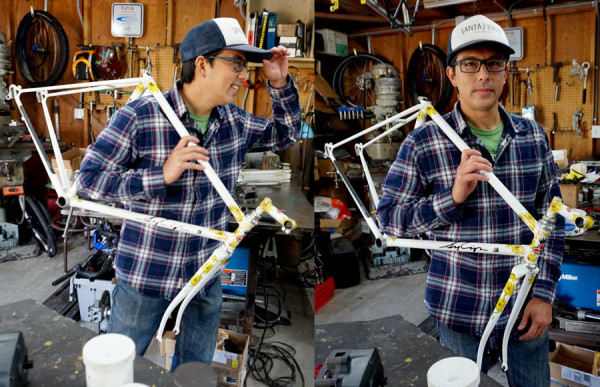

JEREMY: These frames here are about to go to paint. Right now I’m in the middle of a big production run for Shimano. I’m doing e-bikes for them. I built one for NAHBS to show. Shimano wanted fifteen of these for their dealers, for their reps to go around and show people. For a big company, they are good about working with small people. I’ve been working with them since the 90’s. Anytime they need a prototype or a one off.

BIKERUMOR: What’s your lead time?

JEREMY: 4-5 months for a simple – like this simple road frame. Nothing special.

BIKERUMOR: Who do you have painting your stuff these days? I don’t see a booth.

JEREMY: I don’t do my paint anymore. I basically send it all to a place called West Coast Powder Coating down in San Francisco. Ironic because when my shop was in the city, we were driving our bikes up here to get powder coated. The shop I moved out of just a year ago? The powder coating shop was in there. And he was a good friend of ours. We eventually bought him out. When Jay moved to Portland and I was running the business myself, it was too much for me to handle. I had to get a manager in here and running another business kinda. We sold all the powder coating equipment and basically started just building myself again. And I tried to look for a powder coater, and I found the guy back in the city!

BIKERUMOR: So are these all in process?

JEREMY: In process for finish. Some of these are repairs. Yeah, there are some bikes in repair. The ones that are in process as far as new are down here. As far as machines, that lathe is set up for just reaming. These are set up for just mitering- mitering machines.

BIKERUMOR: Do you have stock geometries that allow you to move things through quickly? Or is each custom?

JEREMY: Right now, they are pretty much completely custom. I did have some stock geometries on my webpage… so people could just get, like, a medium mountain bike. They still do that, but I don’t advertise that anymore. An older customer will come in and say, I fit on your stock medium. But this is all recent; I just got a new website. No more stock sizes- just because everything was made one at a time anyway. So my stock sizes now are if someone comes up to me and says this is the- give me all their dimensions. I consider that a stock bike and I charge a little less. This is the top tube I want. This is the seat tube I want.

BIKERUMOR: Something you can easily plug in.

JEREMY: Exactly.

BIKERUMOR: Fully custom with that kind of throughput is pretty crazy.

JEREMY: It’s my big joke is, yeah, I had such a big space, 3000 square feet. I used to have to walk from one side of the shop to the other to do one thing. I’m so much more productive in here. My saw is really close by. My mill is really close by. And I don’t have to commute! I just come in here in the morning and just start working! And one of the reasons- my wife was working full time. I was picking the kids up from school, driving downtown to meet people, driving back home. It was getting really crazy. After I got settled in here, she wanted to stay home with the kids. And eventually she quit her job. I do this full time now… I was part time for a little while.

BIKERUMOR: Part time with the massive space? Or just in here?

JEREMY: Part time because I had to pick up the kids from school- I mean, I was still building full time.

BIKERUMOR: But that’s 3 hours of your day…

JEREMY: Now she does all that, I’m in here pretty much all day.

BIKERUMOR: Are you building for any clients right now? You’ve done batches for other companies.

JEREMY: Mountain Goat I still do. They’ll do a little ten bike run. They are probably the only ones. I used to do some bikes for Steelhead Bikes. I think they are up in the Midwest somewhere. A couple companies like that. That’s pretty much just it. And Shimano is a once a year thing. Every time there is a trade show I’ll do something for them. A show bike. Anytime they have any new parts they want to put on something and they don’t want to do just a stock frame. I work with them like once a year pretty much. And this is probably one of the largest they’ve ever done as far as a run. And it’s not conventional bikes though.

BIKERUMOR: It’s cool they are tapping you for this. I’m not opposed to e-bikes.

JEREMY: They are fun, I think. I used to be totally against them, but now that I’ve ridden one, I’m like wow, this thing is pretty rocking.

BIKERUMOR: So we just came from Curtis [Inglis].

JEREMY: We used to live together.

BIKERUMOR: You pop up a lot in what he talks about as far as formative stories. You guys were complicate opposite ends of the spectrum as far as where you came from. You came from a pretty heavy pedigree of builders and apprentices. You can draw this American builder family tree and see where you fit in it. Whereas Curtis didn’t know how to slot stays until he moved in with you.

JEREMY: Well, he learned to build from Bob Seals.

BIKERUMOR: That’s really cool. I kind of like the way they look not slotted. Cupped in there with all that brass. It looks pretty cool. I know it’s not the classic way to do it. That must have been really funny having you in the same place, like the odd couple.

JEREMY: The fact that you’re reminding me of it- it’s kind of funny. I remember my first shop which was in Fremont at the time. This was when we were both starting out. And he didn’t know how to build straight bikes! How do I miter this? The tubes are straight… what do I do with this? I helped him with his first road bike… his first straight tubed road bike. And it was just funny. I’d just met him at the time- we’d seen each other at races.

BIKERUMOR: It’s really interesting- that dichotomy of personalities, moving to San Francisco at the same time, in 95-96, at the same time American Mountain bike infrastructure, all those CNC guys, just as they kind of imploded all at once. You want to talk about that? Because it must have been stressful from a small builder standpoint. Or was that an opportunity?

JEREMY: I don’t even know- so those were much bigger companies than we were.

BIKERUMOR: But still small fish from a bigger perspective.

JEREMY: Oh for sure. I don’t think we thought about that stuff.

BIKERUMOR: Ha, Curtis did. He was having a rough time trying to figure out Retrotec and Inglis..

JEREMY: For me, I saw it as opportunity. For example- so close by was Bontrager, Salsa, and those companies. And when those guys started going out or selling, I saw it as opportunity. We bought all kinds of stuff from those guys.

BIKERUMOR: Machinery…

JEREMY: Machinery, tubing, you name it. I went to a couple different companies buying stuff. I don’t think I thought of it as a bad thing. It was kind of a weird thing. And speaking of that- when I moved up here, a little later than that, maybe 2000, the day I was moving my shop into Santa Rosa with my moving trucks from San Francisco, Ibis was on my same street that I moved into and they were moving out. They had just sold to another investor. And they were moving all their stuff to Montana. So that was strange. Yeah, it was really weird. Ibis is one of those companies that has gone through multiple investors and at the time I was moving up here they were moving out. It was really strange. But then again, I went down there and bought some machines from them.

BIKERUMOR: So it sounds like you’ve gotten the good end of the deal from all this.

JEREMY: I think so. But at the time, the mid-90s, when the bigger companies were going under, I don’t know. I don’t know if I thought about it too much.

BIKERUMOR: When you started working with suspension on a more massive scale – whereas it had been the realm of smaller builders previously, because small builders could move so quickly through iterations and technology – it’s hard for large companies to touch that kind of product evolution. It was just so fast and so diverse. When it started being appropriated by bigger companies, then smaller companies started folding or getting snapped up. And you guys were coming up at the same time. What did that look like? The timing is really interesting to me.

JEREMY: It is. And I think at that time, you’re building stuff – I was trying to get my hands on stuff, like Titus would make [back ends], and Ventana would sell back ends to Curtis at the time. Yeah, when the full suspension thing came out and everyone wanted it, it was like the next thing. I think at that time I was scrambling to call vendors. I’m not an engineer by trade; it’s not my background. This backend is a good thing, and it works. The only thing I can offer is building a front triangle for that system. At that time I was trying to market myself as a totally custom fitting guy… with a suspension that kinda works.

BIKERUMOR: So you learned to build from Albert Eisentraut- guy came up in Chicago.

JEREMY: Yeah. And he did a lot with Cinelli in Italy. So it’s really cool to hear his input and to learn a little bit from him. I’m humbled- it’s cool I built my first bike with him. I love him.

BIKERUMOR: At UBI, right?

JEREMY: And that was his only class that he did, I guess. Maybe two classes there. But it’s cool. I was happy that he was the guy when I signed up for the class, as a teacher he was awesome. And we’ve had an ongoing relationship since then. We were both in the Bay Area for a while. He would come up to the shop and I’d make time to see him. It’s pretty cool. He’s super nice.

BIKERUMOR: So how did you get into frame building?

JEREMY: So I was into biking and I was in Art School in Pasadena, with my brother. I was taking night classes, doing product design classes. He was in illustration. He was later on, started before I did. We were both into biking. I worked part time in a bike shop. The longer I stayed in art school, I was like- designers hardly make anything. You put a design on paper, have an engineer make it. I didn’t want that. I wanted to make stuff with my hands. I wanted to build stuff. So I started calling around to bike companies and eventually, I think I called Salsa. Ross Shafer was the only one I kind of talked to. Everyone else was too big a company, I think. And I didn’t know any small small frame builders at the time.

So Salsa- Ross was really good friends with Paul Sadoff at Rock Lobster. They were best friends and started building bikes together in the bottom of a bike shop in the 70’s. And he said “my buddy Paul occasionally needs help.” He would do production runs of cross bikes every cross season. That was my first apprenticeship job. I called him. We hit it off. And he was like “move home.” My parents lived in Fremont at the time. Moved back home. Drove to Santa Cruz a couple times a week. And when Albert was teaching the class, I took the class with Albert and still worked for Paul.

BIKERUMOR: Did you take the class just because he was instructing it?

JEREMY: I was going to do it anyway. When I was apprenticing for Paul I realized real quick that a small frame building shop like this is not capable of teaching someone… having someone tie up the jig basically. I didn’t want to do that. I was like, you know what? I’m saving up my money. I’m going to do a frame building course and then I’ll come out with a frame. And then I’ll still work for you if you want me to. And that’s what happened. I took the frame building class, came back home, Paul was like “now you know more, come work for me.” I worked for him on and off for four years.

BIKERUMOR: You had to learn how to braze somewhere else.

JEREMY: He taught me, but I didn’t want to tie up his jig while he was trying to build bikes. A lot of people don’t think about this. A lot of apprentices I have don’t think that way. They just want to build for themselves; they don’t realize they are tying up your shop by doing that.

BIKERUMOR: You’ve had help.

JEREMY: That’s why I’m saying that. A lot of apprentices come in and think, I want to build a frame out of here. And I’m like, no, dude, you can’t do that. I’m in the middle of production. You can’t tie up my jig. You’re here to help me. So I always tell people, you don’t want to come into someone’s shop and think you’ll build a frame out of there that month. You should just go build it somewhere else and see what it takes to build one. And then you’ll realize how hard it is and how time consuming it is.

BIKERUMOR: You’re not taking anyone in this shop then.

JEREMY: Actually, in this production run, I’ve got a friend helping me. He’s cutting metal, drilling holes. He’s not a frame builder by any means, and he doesn’t want to be. So I do have someone helping me. But one off bikes? No, I don’t have anyone here.

BIKERUMOR: This is your first bike from UBI. Wow. This paint job is by hand?

JEREMY: That’s Jay. So when we started our business, whoever ordered the frame, we’d be like “what do you like? You want a theme?” That’s what we would offer people. Jay would hand paint something. We have bikes out there with Calvin and Hobbes on them. Cartoon characters. I think that’s what launched our business. What set us apart. Custom bikes with hand painting. I was like, dude, you went to art school, put it to use! We have a lot of mountain bikes with Tribal Patterns. There’s a bunch out there. This is all mid 90’s. After a while, he got tired of doing hand paint jobs. Then after that, it was all powder coat. One color paint jobs.

BIKERUMOR: It was a positive split with Jay, right?

JEREMY: Yeah. He’s at Chris King. We made up a rumor that Jay was eating too much food, eating me out of house and home.

BIKERUMOR: Forgive my complete ignorance, but what bikes do the pennies, quarters, and dimes go on? Why are they a thing?

JEREMY: The first part of that was pennies on mountain bikes. And the only reason is- going back a little further. The only reason I started doing wishbone stays is because v-brakes came out. Until then they looked pretty normal. As soon as v-brakes came out, they were really flexing the stays. So I wanted to use 19mm stays. Larger diameter. Bringing the cross bridge lower. So I started coming out with that wishbone design. I liked it. So I started doing it. The first few were capped from making end-caps. It was pretty time consuming- putting hole saws through flat plate. So I started looking around for companies that were making those 19mm circles. I just happened to put a penny on one one day and hey! It fits! I brazed it on. Sweet! 1 cent for a seat stay cap. The machine shop was charging me 50 cents for each cap. This is why- cheaper and cool!

BIKERUMOR: Were you orienting them in a certain way?

JEREMY: Heads and tails is how I would do it. Drive side was the heads up. When I would get a custom bike I would ask what year they wanted. I found out pretty quickly that 1980 and newer wouldn’t work. They aren’t all copper anymore… so they would just melt. That’s how the penny came about. Then the dimes came out. I started doing the same wishbone stay for cross bikes. The dimes worked on 15mm stays.

BIKERUMOR: Neato!

JEREMY: We wipe the powder off before we bake it.

BIKERUMOR: So you’ve done a lot of stuff- cargo trikes, mountain bikes, e-bikes, road bikes, track bikes, commuters, cross bikes… what haven’t you done?

JEREMY: I’ve never done a unicycle.

BIKERUMOR: Do you want to?

JEREMY: I don’t know! Custom unicycles… I don’t know how to ride one.