As the story goes, two good friends Benedikt Skulason and Gudberg Bjornsson were chatting over beers about how to use the pair’s industrial design and composites experience to do something more fun. The result was a complete rethink of the modern suspension fork, splitting the difference between lightweight rigid ones and short travel XC forks. In the two short years since the Lauf leaf spring fork debuted, they’ve been shipping every one they can make and growing distribution throughout the world. We’ve tested one and loved it, too.

To introduce the Boost 110mm version of the Trail Racer 29er fork, which saw slight design updates alongside the wider axle accommodation, Lauf brought us to their Reykjavik, Iceland, headquarters for a tour followed by some amazing riding throughout the country.

Two of the most striking ornaments in their office were these first generation test mules, designed to prove the concept before making the jump to composites…

Their office is located in downtown Reykjavik, in a somewhat touristy location filled with shopping on the streets leading to the harbor. Their 3rd floor perch lets them look over it all and is compact, housing this work space for all of the employees, a small conference room, a testing room, and a workshop.

Across from the desks is the bar, which they built to serve home brews crafted by the employees themselves. It was tasty.

Above their current office is Benedikt’s fathers office, where a spiral staircase leads to this loft. It’s here the original idea took shape.

Outside that top floor location is a sweeping panoramic view of Reykjavik and Iceland’s distant mountains (and volcanoes!).

Still sitting in the loft is the first carbon prototype, built entirely in house.

It’s a far thinner, sleeker version than the production models we’re riding today.

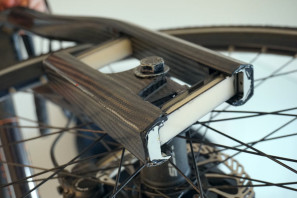

A rudimentary bolt-in thru axle was itself held in place with a bolt-on faceplate. Not pretty, but it got the job done, and the fork still works perfectly.

That fork and other early carbon prototypes were molded in house from alloy molds made nearby.

Note the insert on the top left that created the space for the leaf springs to be inserted and bonded.

Their curing oven now serves as a table, upon which they had a delicious assortment of local foods for us during our visit.

But we’re getting ahead of things a bit…back to the originals. This beast was the first rideable prototype. It was big, and it was heavy. But it proved the idea worked.

Yep, that’s a steel crown with straight steerer, and it was put on their hardtail “commuter” mountain bike to test.

The next version looked a little better and weighed a lot less, but still wasn’t light by any stretch. This led to the first carbon prototype shown above, which led to the second carbon prototype:

Carbon fork #2 started looking more like the current version, albeit still much slimmer.

Like the others, it’s still perfectly rideable.

Some cutaways and closeups of the early models.

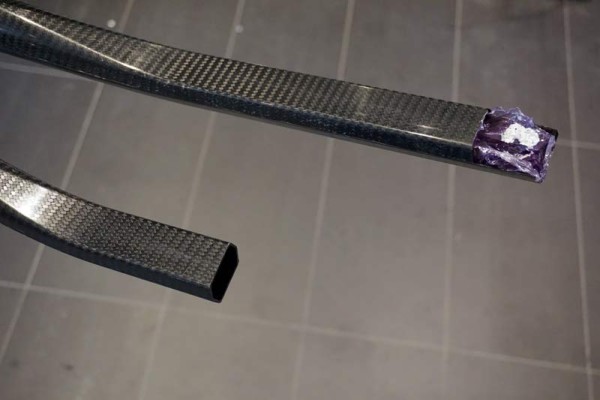

Fast forward to the current forks and the layup and shaping is much more advanced.

They use a small piece of structural foam inside to soften the corner. Carbon fibers like a rounder bend as corners and creases can become weak spots, so this solution let them make the fork stronger while still keeping the external shapes needed for proper function.

The leaf spring blades are made in Germany, then sent to Taiwan for assembly into the forks. The material is a fiberglass that’s used for ballistic protection. One of the questions most often asked is how something with no damping can ride well, to which they say the material isn’t like a metal spring that snaps back instantly. Rather, these return slightly slower and in a more controlled manner. It’s still quick, and slow riding can give the impression they’re bouncy, but at speed it does its job of smoothing the terrain and taking the edge off.

And they’re tough…this is me giving it everything I had. They haven’t managed to break one yet, and I sure as heck couldn’t get it anywhere near a breaking point despite flexing it further than it does on my bike.

Their workshop room was crammed full of bike boxes during our visit since they had to build quite a few bikes for everyone to ride. Here they machine a few small bits for prototyping and testing, but it’s mainly used for assembly and messing around with competitors’ products. And storage.

The testing room contains the Spin Doctor, a giant wooden wheel that puts 40kg (88lbs) of weight on a fork with wheel and tire and runs it through 100,000 cycles.

That’s equivalent to about 5 years of riding. Which is with zero maintenance, a big selling point compared to forks with seals, gaskets, oil and more.

This machine cycles the springs through 40mm of travel for 100,ooo cycles and then they test it to see how much it’s softened. If the flex increase is less than 10% then they consider that a pass.

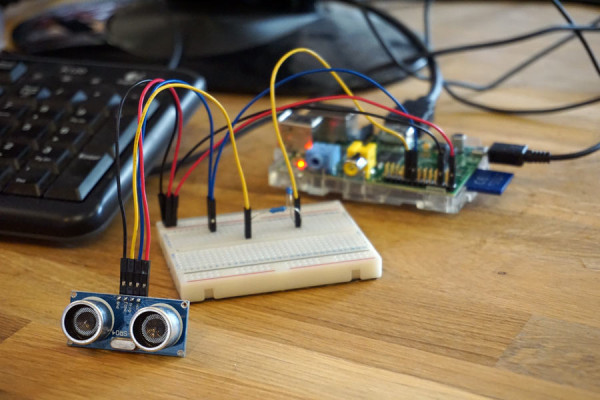

This Arduino (or Raspberry Pi, I can’t remember which) kit was rigged up to measure movement. They’re testing it as a way to measure compression cycles more accurately, among other things. Always tinkering.

The Lauf Trail Racer fork was born out of a need to “absorb the ride” without the weight or complication of a damped, longer travel suspension fork. Despite the size of the mountains surrounding them and throughout the rest of the country, their trails are mostly smooth, and the 60mm of lightweight travel is all that’s needed. To prove it, they took us riding on local XC loops and way, way out into the national parks and glaciers for some fat biking.

The scenery in Iceland is amazing, and these are but a few pics that don’t come close to doing it justice. And the amazing thing is that it’s all accessible, assuming you have the right vehicle to get there. A fat bike is one such vehicle, but we shuttled around via monster truck (keep reading) and helicoptor (I know, I know, this is the life) to make the most of the couple days we had there. I’m pretty sure Iceland’s tourism bureau helped support this trip as Lauf isn’t that big a company yet. The country also provides grants for new businesses that are developing novel and promising tech, products or other ideas. Lauf received just such a grant in 2011 to get things up and running, but it wasn’t until 2013 that they had their product ready to unveil.

Above is Seljalandsfoss waterfall, which drops 65 meters off an old sea cliff. You can walk behind it, and there are several other falls and camping nearby.

The riverbeds in some areas are wider than several football fields are long, mostly made up of dark volcanic rock. This is en route to Þórsmörk nature reserve, where we cabin camped for an evening before setting back across it and into the hills on fat bikes equipped with Lauf’s Carbonara fork.

Our camping spot, which remarkably has a daily bus service running to and from it and has 3G cell service…as did most all of the very remote drive out here.

We visited at the end of June and this was about 10pm. My flight in had the sun on one horizon and the moon on the other, and it never really got dark. Eyeshades are highly recommended, but your internal clock will still get completely wrecked.

Back on the western side was Langjökull, Europe’s second largest glacier. On the top of it is a man-made tunnel, in which they held a fat bike race followed by dinner:

It was as crazy as it sounds, racing fat bikes with studded tires through the inside of a glacier. While you may not be able to bring your bike, the tunnel is open to the public. Check it out at IntoTheGlacier.is.

If you really want to see all of Iceland by car, you’ll want something with tires like this. Lauf rented two of these for most of our commutes, which were every bit as awesome as you might imagine. These were at the extreme end of the spectrum, but a lot of vehicles had oversized tires for floating on top of the snow.

Christmas list: done. They carry a compressor to let air in and out depending on terrain. The Sprinter’s driver said he’ll go as low as 1-2psi on really soft, deep snow.

Into The Glacier gets people up and down the glacier from a lower parking lot in this bus, which can change tire pressure on the fly. The entire experience was amazing, huge thanks to Lauf for showing us around their country and lining up such an adventure. If you’re interested, or planning a trip to Europe, check out Iceland Air, which has a free stopover deal running as of this story going live that will let you extend a layover for days in Iceland en route from the U.S. to Europe (or vice versa) without any increase in airfare.

As for Lauf, what’s next for the company? Honestly, when I got the invite for the event, I was expecting a gravel or cyclocross fork. So why not? For starters, they’ve tested the Trail 29er fork on a Salsa gravel bike and it works even if the geometry isn’t perfect. Everyone wants a 500g “suspension fork” for that category but at present it’s simply not possible…they can’t get that much lighter than their current 970g. That said, it is on their minds and on their roadmap for 2017 or beyond, they just don’t have any concrete plans that can be shared other than to say the current plan is about an inch of travel.

They’re also looking at additional opportunities in the fat bike and XC markets.