If you missed the big news on Thursday, there’s a new bottom bracket standard in town. Now before you start sharpening those pitchforks, this one appears to be a bit of a different animal. The short of it is that it uses the same shell as a PF30 bottom bracket, but it is threaded to eliminate the press fit part of the equation.

A true collaboration between companies, at the Philly Bike Expo you could basically take in every step of the process by walking from one adjacent booth to another. Start at Paragon Machine Works for the Bottom Bracket shells, move over to White Industries for bottom brackets, and finish at Engin Cycles for the complete build (and the prototype White Industries T47 crankset)…

Custom frames will start with the new T47 BB shell from Paragon Machine Works in steel or titanium. As mentioned in the last post, these are the same shells for PF30, just machined with a M47x1 metric thread. Paragon Machine Works will also be offering taps that will fit standard Park Tool Tap handles so that existing frames can be modified. Yes, if you have a metal frame with a PF30 or BB386 shell you can bring it to a qualified mechanic/frame builder to cut threads for the T47 BB. Not only that, but even after the shell is threaded, the bottom brackets should still work with thread together pressfit bottom brackets which would come in handy if you wanted to use something like the Beer Components PF30 Eccentric BB adapter.

In addition to White Industries and Chris King, Enduro will also be making T47 compatible bottom bracket s for both internal and external cup applications. External cups will be used on 68/73mm shells while the internal cups would be used for 86mm shells. Alec White who is one of the creative minds behind the concept says that eventually there should be a fitment to cover almost the entire spectrum of bikes and White Industries will be putting together a compatibility chart for all of the various cranks and bottom brackets in the near future.

These bottom brackets were actually made in a week’s time and rushed to the show where they arrived early this afternoon. Along with the bottom brackets, Enduro will have a matching tool socket, the BBT-015, which mimics the larger BBT-025 for the internal cups.

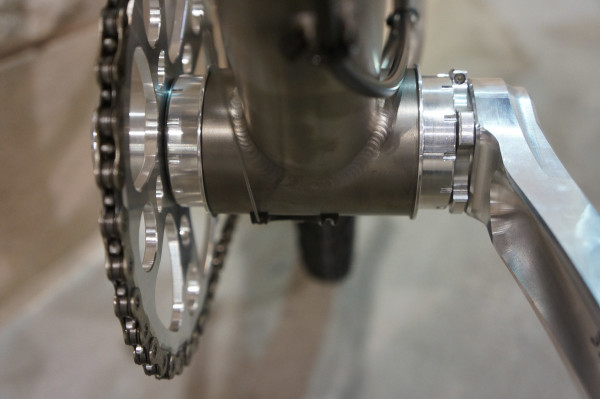

We already got a sneak peek at the T47 BB from White Industries, but what we didn’t see was their prototype crankset built around the standard. Obviously, since T47 BBs are compatible with current cranks with both 24 or 30mm spindles, the White Industries crank will work on other BBs as well, but they have built it with their bottom brackets in mind. Still in prototype phase (if the Sharpie wasn’t a dead giveaway), the White Industries T47 cups are built to eliminate the need for spacers and includes an adjustable preload collar.

The crank was hung on a beautiful bike from Engin Cycles which is covered here.