While purpose-built components are almost always best, the rapid change of standards and options these days means there are a LOT of us sitting on expensive inventory of well-loved parts that we just don’t want to give up. Wheels, in particular, can be one of the more personal items (and more expensive), and can alone be reason enough not to upgrade to a newer bike if compatibility isn’t there.

With that in mind, Lindarets adds to their line of adapters with the new Boostinator. It’s an end cap and disc brake rotor spacer set that converts your standard 100/142 thru axle mountain bike hubs to fit the wider 110/148 Boost spacing coming on modern frames…

The Boostinator came about at the request of Bikeworks Albuquerque, who sell a lot of Plus bikes and high end wheels and had customers wanting a solution. They provided Lindarets with bikes and parts to test prototype adapters on, and their customers agreed to be guinea pigs.

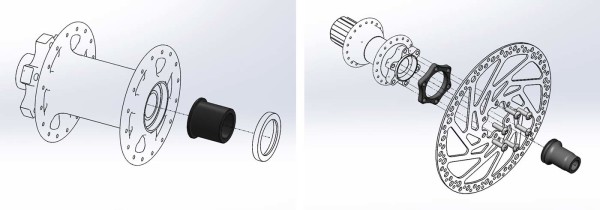

The solution is simple – new end caps to change the hub’s width, and a disc brake rotor spacer for the rear.

The front hub conversion is simply a single spacer that pushes the entire wheel away from the driveside. This means it works with Centerlock or 6-Bolt up front. The rear uses a single hub spacer that pushes the entire hub towards the driveside in order to maintain proper cassette position. A 6-bolt disc rotor spacer then pushes the rotor back into the proper spot for your caliper, but means it won’t work with Centerlock hubs.

Lindarets founder Marc Basiliere says they’ve tested the included longer bolts extensively and haven’t had any issues with breakage. That said, you’ll need to use thread lock on the bolts and keep your rotor diameter at 183mm or under. And as for hub stiffness, the bearings are still supported by the thru-axle, not the end caps, so you shouldn’t lose any stiffness. It won’t be as stiff as a true Boost hub, but it’s a heck of a lot cheaper.

It’s not all about making your treasured hoops compatible with a new frame, though. It could just open up new uses for that 27.5+ bike when summer race season rolls about and you wanna stuff a lightweight set of 29er wheels in there without committing to a whole new wheelset. Options, baby!

A wheel re-dish is required, but Marc says spokes generally have more than enough threaded area and that a typical re-dish to make the wheels work amounts to less than a full turn of the nipple and a change of less than 0.5mm of effective spoke length, which is enough to shift the rim 3-5mm from its original position and center the tire in the frame or fork.

If you bought your plus bike complete, chances are good the chainline is already optimized, it’s worth taking a look to ensure your tire and chain clear each other when in your easiest gear.

Parts are named for brand and wheel, so “D” means DT Swiss, and “F” or “R” means Front or Rear. You’ll notice not all have front wheel options yet, but they’re in the works. Here’s what’s available:

- Boostinator DR – $39.95 shipped – Available now

- The Boostinator DR is compatible with DT-Swiss 12x142mm Star Ratchet (240- and 350-series) rear hubs with 6-bolt (IS) rotor mounts.

- Centerlock hubs are not supported.

- The Boostinator DR is also compatible with some complete wheels from DT Swiss, Roval (Specialized), Giant, Syncros (Scott), and others that use DT’s Star Ratchet internals.

- Boostinator DF3 – $24.95 shipped – Available early Feb. 2016

- The Boostinator DF3 is compatible with DT-Swiss 15x100mm 350 and 370-series front hubs.

- Centerlock hubs are supported.

- The Boostinator DF3 is also compatible with some complete wheels from DT Swiss.

- Boostinator HR – $39.95 – Available Late Feb. 2016

- The Boostinator HR is compatible with 12x142mm Hope Pro2 hubs.

- Boostinator WR – $39.95 shipped – Available Late Feb. 2016

- The Boostinator WR is compatible with White Industries 12x142mm MI6 and XMR hubs.

- Centerlock hubs are not supported.

- The Boostinator WR is also compatible with some wheels, such as those from Rolf Prima, that use White Insustries hubs.