Driving into Hendersonville, North Carolina, it might not be what you would expect as the U.S. headquarters of Öhlins Suspension. Apparently one of the largest retirement communities in the greater Asheville area, the city is an interesting mix of young, outdoor adventure seeking “early retirees” and the actually retired.

The reason for the location? Well, apart from the close proximity to amazing mountains with endless trails and forest roads, it would seem that NASCAR had a lot to do with the location. Specifically, the proximity to NASCAR teams that would want to use Öhlins’ state of the art 7 post shaker rig chassis dyno.

While the NASCAR connection didn’t quite work out as planned, Öhlins has found Hendersonville to be a great home and has been here since 1997. Which is probably a good thing, especially as they venture into the world of mountain bike suspension. With some of the best trails on the east coast right out their door, Öhlins won’t have to go far to find a great testing location…

I have to say, after growing up watching the best MotoGP and Superbike racers in the world duke it out on Öhlins forks, I was pretty excited to check out the facility. The outside of the building is actually pretty innocuous which is probably on purpose. If more people knew what was actually going on inside it might draw a little too much attention to the joint.

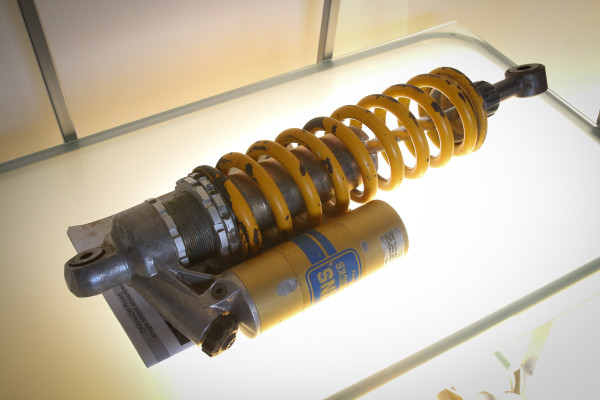

Walk into the lobby and the fun begins. Inside is a small selection of some of the impressive suspension components Öhlins has built their reputation around. At the top is one of their very first rear motocross shocks which other than looking a little beat, is still functional.

For the MotoGP fans out there, this is the actual TRVSP 25 fork used on the premier racing circuit. The 48mm Titanium Nitride coated tubes include a twin tube gas pressurized damping system similar to their new RXF mountain bike fork. However, the mountain bike forks use a mechanical spring to pressurize the fluid instead of the nitrogen pressurization of the motorcycle forks. This pressurization helps prevent the cavitation of the suspension fluid which is basically the formation of bubbles that cause the damping performance to break down. The motorcycle forks are also way bigger with a 25mm main piston. Unless you own a MotoGP race team, these forks are not for sale.

Since you can’t actually buy the $30k MotoGP fork, Öhlins does offer this Superbike fork for those on a budget. It’s a steal at $13k!

Venture in a bit farther past the sales offices and you’ll find the employee bike parking area (which normally has more bikes – it was a slow day) and a Harley. Because why not? Officially, this location serves as the only North American Service Center for Öhlins suspension which includes sales, service, custom tuning, and race support all under one roof.

As part of the service center operations, that also includes dealer training which in this case means motorcycle dealers. The training center offers Öhlins Master Tech training certifications where Ducati dealers and others can come to be certified to work on Öhlins suspension. Of course that means having a Multistrada 1100 S and a 1098(?) present as teaching aides.

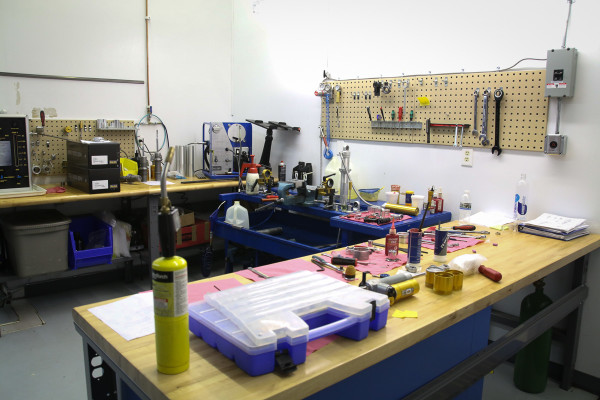

As part of the certification courses, each participant has their own work station complete with a video screen so they can see exactly what the instructor is doing. The whole set up is just as pro as you would expect from a company like Öhlins.

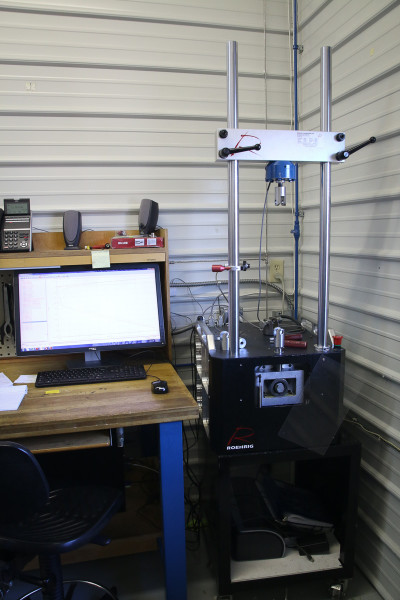

When asked if they were planning similar certification programs for mountain bike suspension techs, the short answer was no. Mostly, due to the cost of this tool above. While monotube dampers can be filled with damping oil and then bled fairly easily, the twin tube damper set up of the RXF requires it to be vacuum filled since the check valves in the system prevent bleeding. To be 100% sure there is no air in the system, it requires one of these vacuum filling machines. At the moment, Öhlins feels that the cost of the machine will be too much for most suspension service centers, so for full damper rebuilds the forks will have to come back to Hendersonville. However, standard maintenance like replacing the wiper seals can be done at the dealer level. For Öhlins, they see mountain bike product as performance first, with user serviceability farther down the line.

Those same vacuum fillers or versions of them are found in both the motorcycle and automotive service centers as well. Compared to the motorcycle world which Öhlins says is a bit more plug and play, the automotive world is more complicated with almost every car requiring a custom set up based on the car, the track, the conditions, etc. Therefore the shocks end up more high tech with different spring rates and valving which are tuned to the race car. That’s basically the reasoning for their $2 million chassis dyno. The 7 post shaker rig can replicate what will happen once the car hits the track and is an important tool for race teams to develop their suspension packages.

Which is why on days like the day I stopped by, you’ll find the Andretti Autosport’s transporter parked outside. If your team has the cash, you can rent out the chassis dyno along with two Öhlins engineers to dial in your race car. Apparently now the rig is used mostly by Indy Car teams. While I wish we could have gotten photos of the dyno, at the moment the Andretti car was on the rig which meant everything inside was top secret – even many of the Öhlins employees weren’t allowed inside.

In addition to the chassis dyno, Öhlins also makes use of a shock dyno (middle, right) which enables them to see exactly what the shock is doing throughout the travel. With the dyno hooked up to the computer, Öhlins can tune the shock to perform exactly as they want before ever installing it on a vehicle.

All this suspension tuning means Öhlins needs springs. a lot of springs…

…but even more o-rings. Every blue bin above is filled with o-rings – about 8,000 sku’s worth.

Just across the parking lot, Öhlins warehouses all of their suspension. With the exception of the Specialized warehouse in Salt Lake City, this is where all of the Öhlins RXF suspension forks will be warehoused and will ship. On the whole, Öhlins’ operation in Hendersonville is probably a little smaller than you might imagine, but every bit as cool.