Late in 2015, we revealed Factor Bikes new models, the UCI Legal ONE, O2 and ONE-S. All of these bikes are linked to a project with the UK’s first Professional Continental Cycling team, One Pro Cycling. Originally starting as a side project from motorsport and automotive company bf1systems, Factor Bikes has grown into a showcase for innovation. In 2009, the company released the Factor 001, a carbon machine that featured split downtube and aerodynamic fork, disc brakes and integrated power meter.

In 2014, Australian ex-professional cyclist and winner of the Tour de France’s green jersey, Baden Cooke, joined Factor Bikes as a consultant. Baden was tasked with creating a UCI legal bike to showcase in the world of professional cycling. Nowadays, Baden is a co-owner of the company with Rob Gitelis, an American who owns a manufacturing company in Taiwan. The 2016 Tour Down Under was chosen as the venue to officially launch the Factor ONE, O2 and ONE-S bikes. I was fortunate to get a few minutes of Baden’s time away from the Factor pop-up booth, and gather details and photos of the Factor ONE.

The most interesting feature of the ONE is the bike’s split downtube. Designed to be the most aerodynamic bicycle available, the company claims that turbulent air from the front wheel passes through the downtube, rather than around it. According to Factor, the split downtube saves 100 grams of aerodynamic drag compared to a regular downtube in wind tunnel testing. That’s a claimed saving of one second per kilometer.

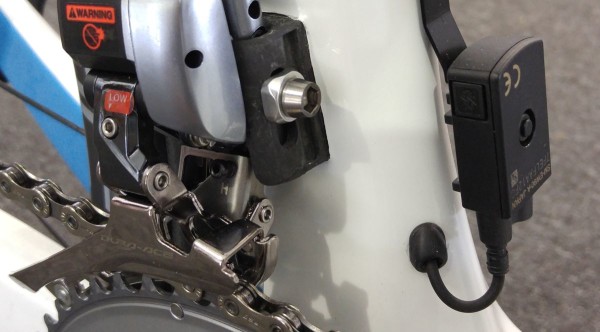

The feature sure to draw the ire of some is the ONE’s location of Shimano’s Dura-Ace Di2 Junction A box. Typically slung beneath the stem or in a concealed compartment on some aero bikes, Factor places it below the cage bolts of the rear bottle cage. Factor cite the location as convenient for charging or adjustment of the system. While convenient, there is no denying this is a dirty area of the bike, attracting the sweat from water bottles or road grime on a wet day.

Aerodynamics continue to the ONE’s integrated handlebars and stem.

Factor eschews potentially troublesome and proprietary aero brakes with their choice of Dura-Ace 9000 series calipers.

Junctions around the seatpost and seatstays are kept clean, devoid of aerodynamic drag. The Dura-Ace rear brake is shifted to the underside of the bike, behind and below the bottom bracket.

The Dura-Ace 9000 series crankset interfaces with the ONE’s BBRight bottom bracket, rotating on CeramicSpeed bearings.

CeramicSpeed bearings are also installed into the ONE’s Black Inc 50mm carbon clincher wheels and headset. Those bearings add a considerable premium to the ONE’s overall retail price.

Priced at $13,200 USD including tax, the Factor ONE isn’t within the budget of every cyclist. However, compared to the offerings of big-name aero bikes, the ONE is priced competitively and remains exclusive.

Coming soon, the Factor One S of ONE Pro Cycling’s Steel Von Hoff. Watch this space!

Photos and article by Gravel Cyclist.

Jayson O’Mahoney is the Gravel Cyclist: A website about the Gravel Cycling Experience..