If you really think about what you want, it’s not that you WANT a front derailleur and double chainring. You want range. And 1×11 provided that for many people, with 2x for the rest.

According to SRAM, global spec for 3x drivetrains drops 70% every year, and has done so year over year for quite some time. Now, they say even 2x spec is diminishing as 1x has become fully developed across the price spectrum. The growth was a surprise for them, actually. When they first made XX1, they thought it might be a niche product. That was 2007. Now, between road, mountain and cyclocross, they have nine different 1x groups because demand has far exceeded expectations.

But there were hold outs. Even with a 420% range on their 1×11, some riders wanted more. SRAM’s GX 2×11 boasts a ridiculous 630% range, but most 2×10 setups are in the ~515% range. But, then you’ve got the weight and complexity of a front derailleur and multiple chainrings. Surely there was a way, so they started tinkering.

The result is Eagle, a 1×12 group with 10-50 cassette spread that gets you darn close to what a double provides. But who needs that kind of range? Turns out even their top pros wanted it after trying it. Dominant riders like Nino Schurter and Jerome Clementz. Why? Not because they need more range, but because they can go faster…

Basically, Eagle is substantially lighter than a 2x, has a 500% range, and makes the bike simpler. In other words, it frees you from ever needing a front derailleur again. How serious is SRAM about this? Drivetrain product manager Chris Hilton says they’ll never tell us about another mountain bike front derailleur again. They are no longer doing any development work on mountain bike front derailleurs, and those engineers have been moved to other projects. They’re dead.

SIDEBAR: The Eagle gets its name because the bird has a massive range, is an apex predator and respected as a symbol of freedom throughout the world.

At launch, Eagle will be a premium offering at the XX1 and X01 level. Because the chainrings are direct mount, you’ll be able to build it up with lower level cranks to save a little money (and expect OEM buyers to do just that on MY17 bikes). More on that in a bit. First, it’s worth mentioning that this is a complete system. SRAM’s not a derailleur company, they’re a drivetrain company. So, in their mind, if you’re not designing a drivetrain as a system, how do you know that it’s optimized to work together as well as possible?

And optimized it is, far beyond just adding another cog. So we’re covering this in three posts – this overview that dives into each component’s technical details, a specs and actual weights story, and our first ride review. Here we go:

X-DOME CASSETTE

The most visible element of Eagle is the massive cassette. It’s about the same diameter as a 180mm brake rotor. It mounts to their existing XD Driver Body freehub and the 10-tooth cog location is the same, which was necessary to fit standard frames. That was an important consideration, they didn’t want to force anyone to buy a new wheel or frame to use this group. Compared to the 11-speed cassette, the 42-tooth cog is slightly more outboard than where it was before, which means better chainline on that then with the 11-speed groups. The 50-tooth is slightly inboard, but because of the wheel’s dish, it maintains proper clearance for both it and the derailleur.

The actual 50 tooth count came about after testing various numbers. Counterintuitively, they say it’s not always harder to make a chain move across bigger gaps, it just depends on the timing between them. Fifty became the right number in that it provided the smoothest shifts between it and the 42. Everything below it is essentially the original 11-speed XX1 cog’s 10-42, gear steps and all. They’re just a little closer together.

Shift ramps (marked in red and green) and tooth shaping on the two largest cogs help move the chain quickly and efficiently.

The Eagle X-Dome cassettes are machined out of solid steel, just like the XX1 and RED Power Dome cassettes, with the largest cog being alloy to save weight.

Both the XX1 and X01 cassettes are the same except the color. Both get a PVD (Physical Vapor Deposition) Titanium Nitride coating, with XX1’s being gold and X01’s being black. The coating provides corrosion resistance and some friction reduction. The same coating is used on the chains for each group, too.

X-SYNC 2 CHAINRING

The new Eagle chainring’s design is a balance between chain wear and chain retention. The teeth are more radically shaped, with more of a shark tooth design with notches and grooves. This shape came about in part by looking at how their chainrings wore in the field. And by noticing that as riders went to a 1x system, many ended up running smaller and smaller chainrings, which meant the chain load was being spread across fewer teeth, which sped up wear.

Frank Schmidt, SRAM’s MTB drivetrain engineering manager, said with the original design, most of the load is taken by the first couple teeth as the chain engages the ring, and that causes a majority of the wear that ends up creating a sort of shark tooth shape. These new shapes help disperse that load across more teeth, which ends up reducing wear.

The tooth profile looks counterintuitive, but it’s doing several things. First, it’s preemptively putting part of the hook shaped pattern into the teeth that ends up occurring with normal wear. Then the top is notched back more to prevent that shark tooth “hook” from ever forming, which means even as the ring wears, it won’t allow chain suck.

The shape also distributes the load across more teeth – almost all the way around rather than the first two or three teeth taking the bulk of the load. The result is chainrings that have more than 4x the life of their first gen X-Sync chainrings.

Just as important as chain retention is letting it go when the time is right. We spun the cranks fast and slow and the chain glides off the bottom of the ring effortlessly…it’s very smooth. And it should stay that way no matter the conditions; all of those little nicks, grooves and angles are there to shed mud and grime.

All Eagle chainrings are direct mount only, and at launch they’ll offer 30/32/34/38 tooth counts for OEM spec, 32 tooth only for aftermarket. Schmidt says they have some 40s in testing under athletes, and their Force 1 rings run up to 54, so it’s not a stretch to think we’ll see bigger rings for more applications in the future.

And bigger chainrings are part of the story for their pro athletes. If they’re comfortable with the easy end of the cassette, they can go up 4 teeth on a chainring and keep about the same low end range on the new 50-tooth cog. But, now their top end just got way, way faster. Think 36-10 versus 32-10 when hammering down the straights and you can see why Nino might like this. And, it’s an ultra stiff chainring, they say there’s virtually no deflection even under insane power.

CHAIN

The design required a new chain design, too. That decision wasn’t just so they could make a proprietary part, it was because they needed to design it as a system to ensure proper shifting, retention and wear resistance. And, yes, it needed to be just a bit thinner.

Cassette cog spacing is 3.8mm on their 11-speed groups, but that shrinks to 3.65mm for Eagle’s 12 speed (with a slight bit more room between the smallest two cogs to accommodate the angle of the chain there). Chain width goes from 5.6mm on 11 speed to 5.25mm with 12 speed. The change in width isn’t really even important, it’s everything else they did to make it the best, strongest, quietest and smoothest chain. Ever.

“In order to fit (12 speeds) on bikes as they’re designed today, we had to go in and look at the chain,” said Schmidt. “At the same time, there’ve been advancements in chain manufacturing and design. Those advancements could have been applied to 10 or 11 speed or any other chain (but the investment of new machinery and tooling meant it made sense to apply it to this new group).”

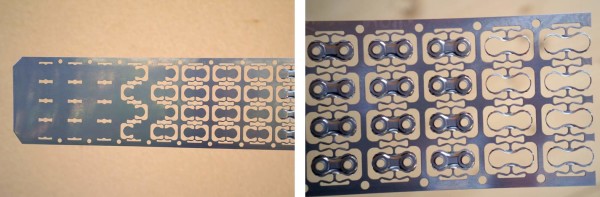

A new chain manufacturing process was a massive investment for them, requiring all new tooling and machines at their German Portugal manufacturing plant. The sheets from which the chain plates are stamped start out flatter, and the more intensive plate shaping at the pin hole allows the pin to sit flush inside a chamfered hole. Completely flat material lets them perform more precise, consistent riveting, and that means the chain is less likely to fail because the plates are held in place more securely.

All told, there are 37 steps in each chain plate’s development. The panoramic spread above shows most of the process (click to enlarge). The changes from step to step are minimal, but each one is making slight changes to the shape of the pin holes and inside edges, and that’s the real secret to the new chain:

Called Smooth Link, the inside faces of the links no longer used angled chamfers. That feature was there to assist front shifting, but was no longer needed. And, in fact, they say was creating noise and hastening chainring wear because that chamfer would grind mud against the teeth.

The new design uses a constant radius on the inside face on both inner and outer links, which glides more smoothly onto and off of the teeth. That reduces noise and dramatically reduces chainring wear.

The small chamfer on the outside pin holes allow the pin to sit flush. As they’re pressed in, they fill in the chamfer to lock themselves into place. There was 0.1mm pin protrusion on the 11-speed chains, and now they’re down to zero protrusion. That’s a big part of how they were able to squeeze 12 speeds on the same XD Driver Body that their 11-speed cassette fit.

Roller width and dimensions have changed, too, and the inner plates and rollers all get a Hard Chrome treatment to increase their lifespan. The PVD Ti Nitride coatings protect them from rust and play a small role in friction reduction, too.

Put it all together and you end up with a system that runs quieter and smoother than anything they’ve done before, and it’s stronger, too. Win, win, win.

EAGLE SHIFTERS

The X-Actuation trigger shifters look and feel mostly the same. The keep the Zero Loss cable pull method, adjustable thumb lever positioning and Matchmaker-X mounting compatibility.

XX1 uses a carbon top shell and trigger, X01’s body is all aluminum.

Inside, they made a few changes to make the system more robust and improve click feel. They also made the movements a little tighter, necessary to make the smaller movements precise enough for the tighter cog spacing.

EAGLE X-HORIZON REAR DERAILLEUR

The Eagle rear derailleur is functionally similar to its 11-speed counterpart, but there are a number of important upgrades hiding inside.

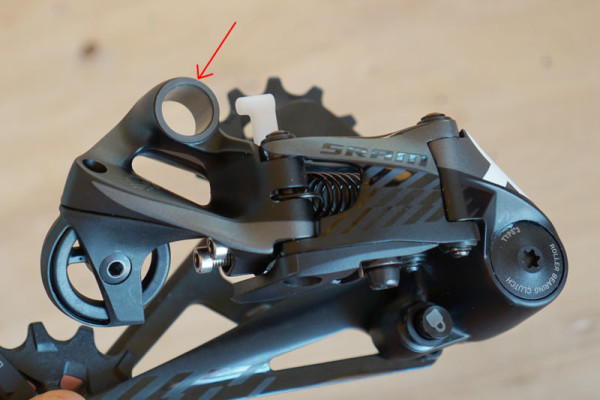

The B-knuckle has been updated to include an Igus bushing on the inside of the knuckle, which helps the derailleur move more smoothly through its range.

The mounting bolt gets a sleeve washer to prevent over tightening the derailleur to the hanger, which could end up causing it to bind up and limit movement. That also helps the system move easier.

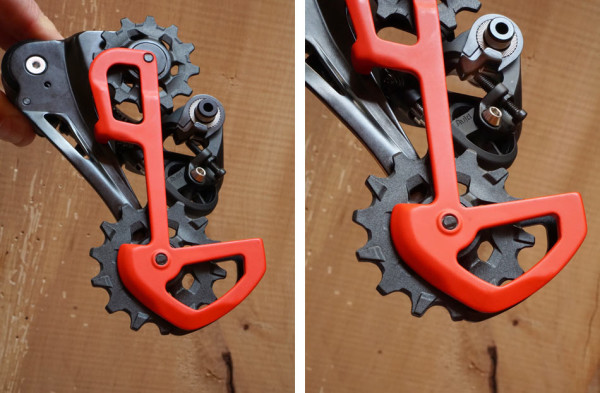

The X-Sync lower pulley wheel has been upsized to 14 teeth compared to the 12-tooth upper wheel. The narrow/wide tooth patterns are there to aid chain management, particularly when cross chaining. The wheel is larger than before because, since there’s more chain wrap, allows for a longer chain to be used without increasing the length of the cage. That’s important because that 50-tooth monster needs a lot more chain, but they had to maintain enough ground clearance for it to be used on any bike (26″ wheels, anyone?).

Differences between models are: XX1 gets a carbon outer pulley cage plate and titanium and alloy hardware. X01’s cage is forged aluminum and it uses stainless steel hardware.

The derailleurs will ship with this installation guide. Marks on the upper wing align with the 50-tooth’s teeth to show how to set the tension screw for proper clearance between the cassette and upper pulley wheel.

The new Type 3 Roller Bearing Clutch gets a revised spring curve to keep pressure on the chain more consistent. The Cage Lock button has been moved back, out of the way, to reduce likelihood of damage in an accident.

EAGLE CRANKS

SRAM has three testing standards for their cranks -XC, All Mountain and Gravity- and until Eagle, all were tested to meet their Gravity standards. That means an XC product like XX1 was completely overbuilt. With Eagle, they wanted to optimize the cranks more for XC, with differentiation between the XX1 and X01 cranks.

For XX1, that meant it didn’t need to handle the massive rock strike impacts of a DH crank, but it needed to have good long-term load handling. To save weight, they used a new hollow core construction, with a carbon layup that produced internal reliefs to save weight. It’s still overbuilt for what’s needed for pure XC -it’s tested to meet their All Mountain standard because they know people will ride it beyond XC- but it’s lighter than ever.

X01 gets a foam core instead of being hollow, with additional carbon laid up around the pedal insert to improve rock strike durability.

XX1 is about 30g lighter than X01, and the XX1 Eagle cranks are about 50g lighter than prior generation XX1/X01 cranks (they were the same, just had different decals). Yet they’re testing stronger than before, and SRAM’s reps say they’re testing stiffer than any other brands’ cranks in that weight class.

Another important upgrade is that these new cranks use the same chainring offset for both GXP and BB30 cranks, and the new Descendant cranks will fit it, too. There’s still Boost and Standard chainrings, but no more GXP vs. BB30 chainrings.

You can use the new Eagle chainrings on existing SRAM 11-speed GXP cranks, too, with the benefits being quieter operation and improved durability. Because it’s not using the new chain, retention will remain as good as before, no better, no worse.

THE FUTURE

Other than using Eagle chainrings on existing 11-speed groups, there is no cross compatibility. That means no mixing and matching other than being able to take advantage of the Eagle’s new chainring tooth profiles.

How quickly will Eagle trickle down? When they launched 2×10 groups in 2009, they released a new 2×10 group on an annual basis. With 1×10, that cycle sped up a bit because there were fewer parts to develop. For Eagle, we’re guessing we’ll see a similar cycle, but they say it’ll be based on OEM and rider demand.

There’s still a lot of full suspension bikes that are built with a front derailleur in mind, but Eagle eliminates that consideration. That removes all sorts of design limitations on tire clearance and pivot placement. It also allows the engineers to truly optimize suspension optimization around a smaller range of chainring tooth counts instead of needing to work well with anything from a 24 to a 38.

Why not go bigger with 13 or 14 speeds? Well, how different are you willing to go? At the moment, they believe consumer acceptance of a radically different design or need for alternate frame, wheel or other standards to accommodate a bigger cassette simple wouldn’t fly. After riding it, we can’t honestly imagine a need for more, but time will tell. There was a lot of off the cuff discussion about alternate transmission ideas, but that, too, requires acceptance of something radically new, both from consumers and the industry.

Will 12 speeds transition to road bikes? We didn’t ask specifically, but our guess is yes. Here’s why: Their new chain is amazing, so it’s only natural its technology will be spread across as much of their product line as possible. SRAM’s XD-R driver body for road bikes already has an additional space in there that would probably allow for a 12-speed cassette to be used without any change in wheel or frame design.

Up next, tech specs and actual weights…