Hot on the heels of Shimano’s XT-level off road e-bike group, SRAM is introducing EX1 for motor-assisted mountain bikes. Why? Because they wanted to create a complete group that addressed the unique demands placed on equipment by an e-MTB. And because that market is growing rapidly regardless of how some folks feel about it and this gives them a complete group to offer as OEM spec.

Marcus Schneider, SRAM Germany’s general manager and e-bike product manager, says “most every e-bike out there now is using standard drivetrain and brake parts. And they’re good, but we thought we could do better.”

What’s different about an e-MTB? Well, there’s more weight, which puts more demand on the brakes, because you still need to stop in the same distance. And with drivetrains, when you shift on a traditional (i.e. human powered) bike, you typically let off the gears slightly, particularly when climbing. But with an e-bike, the motor is continuing to propel the drivetrain forward, so it needs to be able to shift under power.

And when you first hop on a traditional bike, it’s common to shift a bunch of gears at once to get it to the right starting point. And there are plenty of gear steps to help you find just the right one for your human powered bike. But with an e-bike’s immediate torque and power on tap, they didn’t need as many gear steps. In fact, all those extra gears could actually create chain management issues. So, they only needed eight cogs…

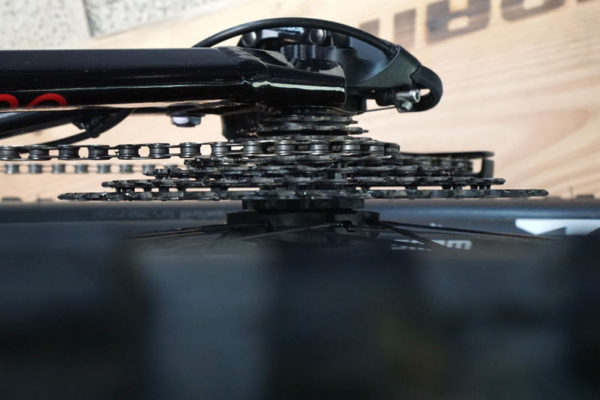

For standard bikes, each gear step is about 14-17%. Their new E-Block cassette pushes that to about 30%. That let them use fewer cogs -eight, to be exact- while still offering a massive gear range. It’s an 11-48 spread, using 11/13/15/18/24/32/40/48t tooth counts. The benefit to that is they could make a narrower cassette, which maintains a better chainline regardless of which gear you’re in.

They also added more aggressive chain management features to the cassette, using the shapes of the inner and outer chain plates to enhance shift quality and speed. They shaped the spider section of each cog to better counter chain forces. It’s a cluster build, putting the five largest cogs on a cluster plus three individual smaller cogs, which slide onto a standard freehub body with a spacer behind it to fill the gap between the it and the hub’s spoke flange.

Since the gear gaps are now larger, the shifters were tweaked to limit shifts to just one at a time so the chain wouldn’t jam up or skip over the larger tooth jumps. They look exactly the same, but the internals are clocked to the new cog spacing.

The rear derailleur gets all the tech of their current X-Horizon units (clutch, etc.), but has been reinforced with a stronger pulley cage.

Connected them to the front is a new chain, PCEX1. It’s only slightly modified from their other non-hollow chains, getting an additional chamfer on the inner plates to improve shifting and chain management. They had customers always asking for stronger chains, but what they found was that once the chain management issues were solved, their chains were plenty strong enough.

For the cranks, they started with one of their forged alloy crank arms, then adjusted the Q-factor inward. Bottom bracket motors are wide, and with a standard crank arm, it can push the Q-factor fairly wide. They’re e-bike specific and use the ISIS mounting standard. They’ll offer alloy direct mount chainrings for the Bosch and Yamaha motor systems in 14/16/18 tooth counts, and a steel 34-tooth 104BCD chainring for Brose motor systems.

The entire system had to be designed in balance. If they made the chainrings, chain or cassette too hard or durable, it could cause the other ones to wear out to fast. So, it’s all designed in harmony to work with the rider and the extra forces put on the system by a motor. At launch, the group does not have aftermarket retail pricing. UPDATE: Yes, they will be sold separately, here’s pricing:

- Crankset – $50 / €55 / £45

- Direct mount chainrings – $20 / €20 / £15

- Rear derailleur – $142 / €165 / £125

- Shifter – $48 / €55 / £40

- Chain – $25 / €30 / £20

- Cassette – $390 / €450 / £345

Bringing it all to a stop are the new Guide RE hydraulic disc brakes. They looked at all the progress they’d made with the Guide series and combined it with the power from their Code series. They used the Guide R lever, which uses their non-linked, bushing based pivot hardware and a cast alloy body. They used this, rather than their higher end levers, because it needed to be very robust in case the bike fell over and landed on it. Because, you know, motors and batteries are heavy.

The levers are ambidextrous, able to be mounted regular or moto style depending on your preference. The DH-level four-piston, two-piece forged alloy calipers use steel-backed sintered metallic pads for better longevity. Retail for the brakeset is $133 / €145 / £112, claimed weight is 415g (800mm hose, 160mm Centerline rotor).