Andrew Low established Low bicycles a mere 6 years ago. Since then the company has come a long way, they’ve developed a track record of creating some of the most advanced aluminum frames out there. Now available, the mki road promises to provide the stiffness of a criterium machine but with the comfort of an all day road hog.

Get the Low down after the break…

The craftsmen at Low take attention to detail to a whole new level. Being a small batch manufacturer that puts out roughly 20 frames a month, it’s safe to say each frame gets the royal treatment.

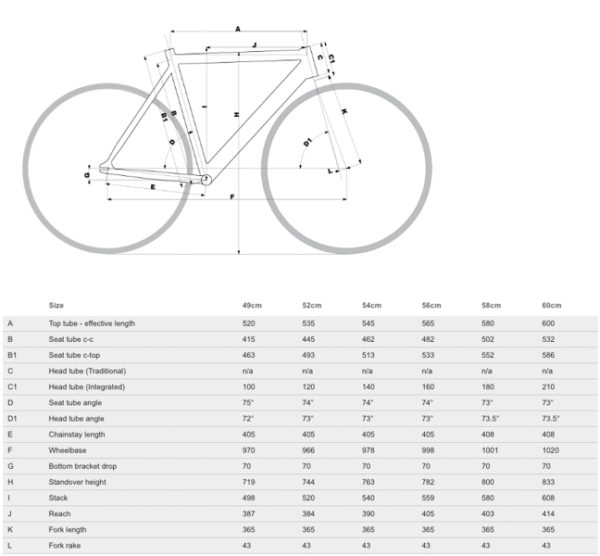

Since we last spotted the mki in March of this year at NAHBS, the bike has gone through some final tweaks. Slight changes have been made to the geometry and tubing selection. Additionally, the bike has been ridden by Low’s factory race team for nearly a year, assuring it’s fully capable of competing with its carbon competitors.

The frame is constructed of various tube shapes, each providing a specific job. The rear triangle and top tube are built with wide and flat tapered tubes. This tube form allows the bike to absorb vertical chatter from rough roads. For added vibration damping, the seat stays are smoothly affixed to the top tube. This supposedly allows some of the vibration to deflect forward rather than up into the riders back. Furthermore, an over-sized oval down tube provides the bike with its “back bone” ensuring horizontal stiffness.

Specifications

- Frame weight: 7005 alloy with external cable stops – 1400g (54cm)

- Fork: ENVE composite 1-1/2′ tapered carbon road

- Dropouts: Road 130mm spacing

- Head tube: 1-1/2″ tapered head tube with drop-in bearing seats

- Bottom Bracket: English threaded 68mm

- Seat post: 27.2mm

- Seat post collar: 31.8mm

- Drivetrain: Sram eTap mechanical brakes

- matte black with white, orange graphics / classic colorways and raw finish also available for upgrade price

The current wait time to get your hands on one is growing, with it currently pushing past 3 months. The frameset option is running $2,500, while the complete build is going for $4,300.