Most times, a catalyst is used to start something. For SwissStop’s latest product, it’s meant to stop something: You.

The new Catalyst disc brake rotors combine a SUS410 stainless steel braking surface with a 7075T6 aluminum spider in a carefully shaped, extensively tested pattern. They say the result is stiff, minimizes vibrations and sheds heat quickly…

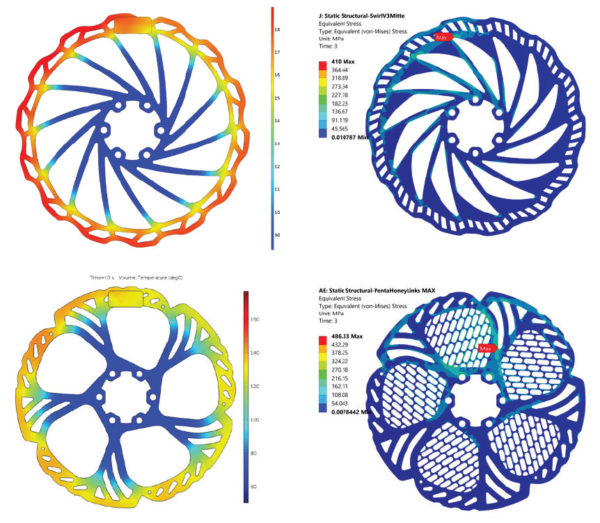

Digital models were created, tested and simulation verified to prove that what they created in their computers reflected reality, then used that program to optimize their own design. It measured for both heat and stiffness, showing where stresses were placed on the rotor during tracking forces. This let them also optimize the shape of the holes in the brake track to minimize pad vibrations, which hopefully means they’ll be very quiet during braking.

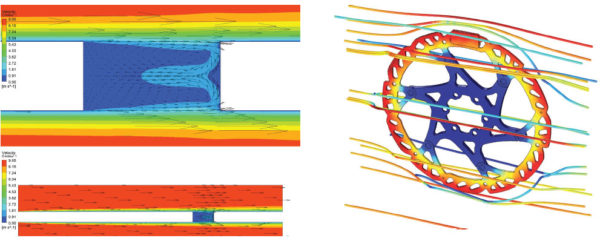

The two-piece design proved to be best at controlling heat, tested through CFD before heading to the trails.

Lab testing showed the rotors required less hand force than a competing model, and they resulted in shorter stopping distances. Part of that comes from adding a little extra material to the braking surface, so they’re not the lightest rotors on the market, but they say the performance improvement is worth a few extra grams:

The 140mm and 203mm rotors are 1.85mm thick, the 160 and 180 are 1.80mm thick. All are compatible with sintered and organic pad compounds, but they’re optimized for use with the SwissStop EXOtherm brake pads.

Pricing and any remaining details to come at Eurobike at the end of August.