Last year, Tyler rocked out a pretty cool little project with this sweet “crush all” Van Dessel Whiskey gravel bike for 2015’s “World’s Funnest bike. The basis for these builds is to take something and tweak it to be the most fun on two wheels. While an opinionated piece it’s fun to see what people come up with so I decided to take a crack at it. I’ve seen and built some unique bikes that just jive like nothing else, and I unintentionally got the chance to do this very thing with a frame I was asked to review.

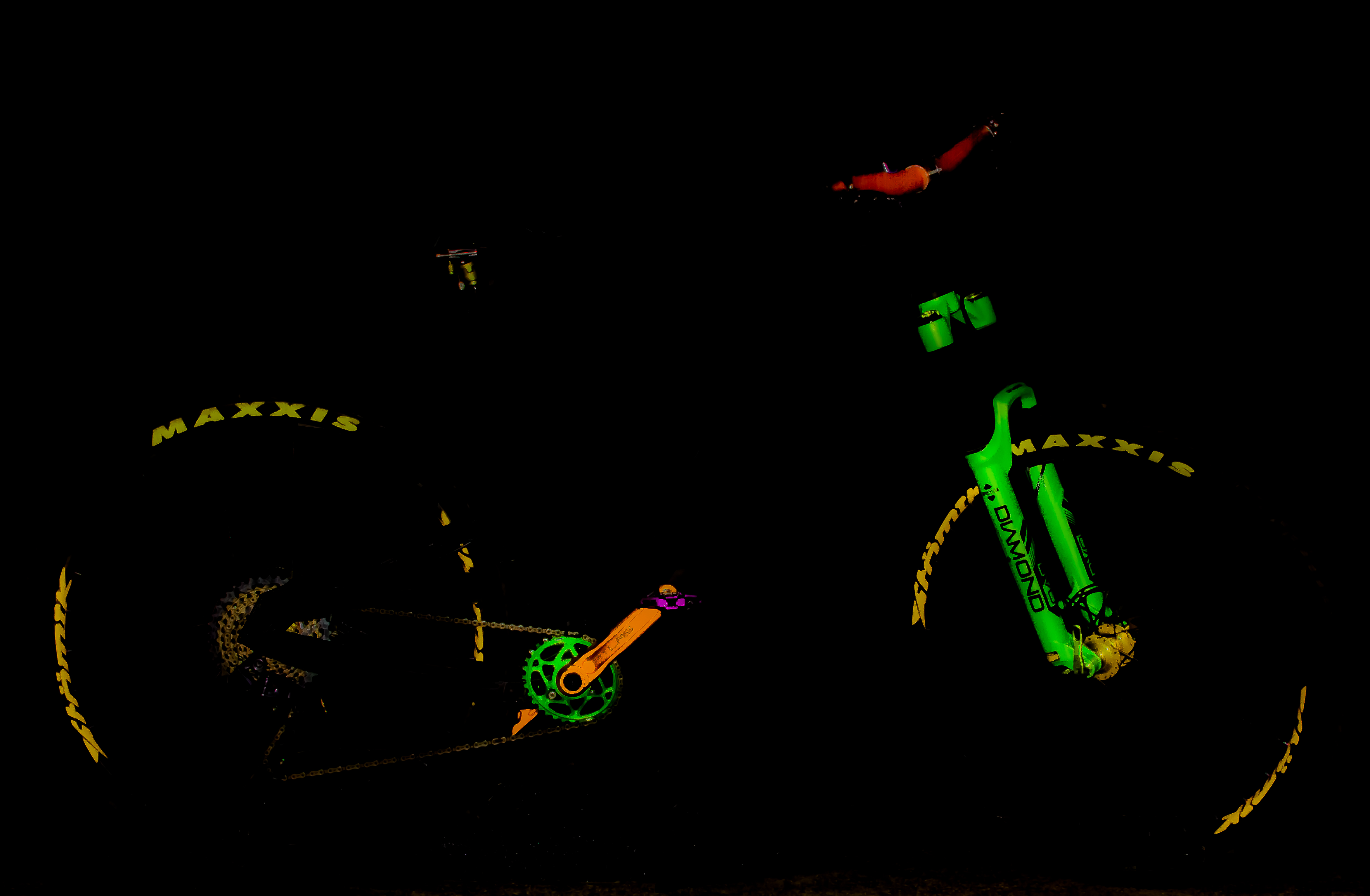

Oh, and this is part one of three as I like to stretch things out a bit… especially when I’m having this good of a time! Check out the pile of parts I came up with and what took my grin to the next level. Also take a look back at what used to make up the ‘world’s funnest bike” from year’s past…

Long story short, I got the chance to review a (pretty sweet) frame, but I would have to build it up to do so. I happen to have a bike I could rob most of the parts from that would mostly transfer over, so I said, “you betcha”! (I’m from Texas and may have said YEEHAW! but let’s keep this internationally friendly). As I was eagerly awaiting the frame’s arrival, I was asked if I could see what I thought of some wheels… tires… then some more wheels… then *fill in the blank*. As things were getting swapped out left and right, I realized this bike just made me batshit happy to ride more than anything in recent years. Not one item matched on the bike so I went with it as I started collecting parts. I left the shifting setup and “old” brakes (important… but more on that in a second) from my personal bike… and because I wouldn’t have changed them out for anything else. I then decided to think back about some of the products I was curious about and started piecing this thing together.

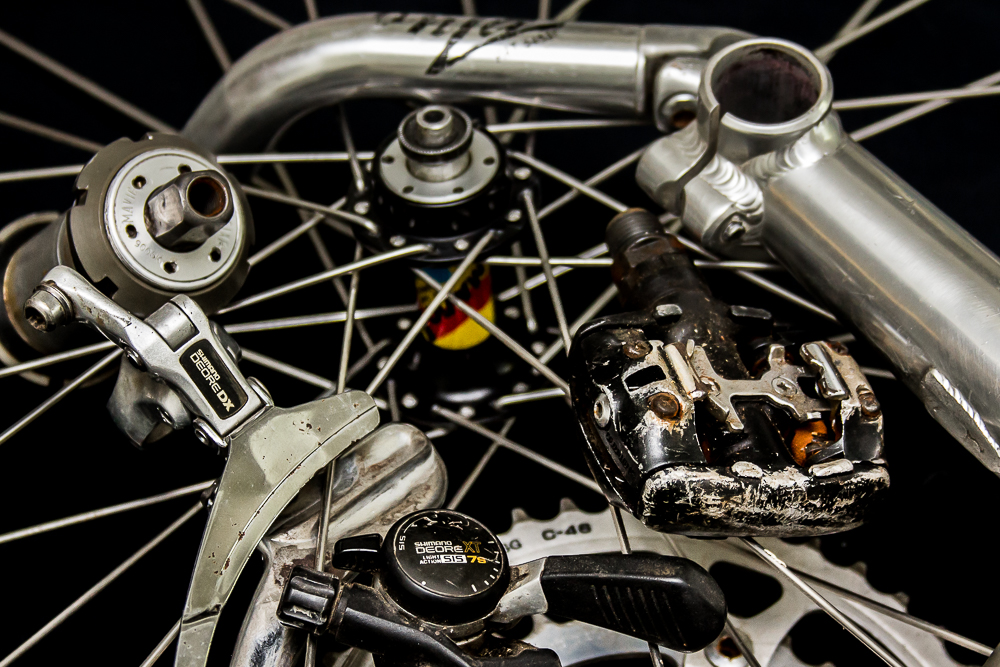

You’ve probably guessed that this is a mountain bike. Not counting BMX, this is how I got my start in cycling and despite loving all things on two wheels, mountain biking and the people it surrounded me with surpasses all when it comes to fun. This isn’t the first “world’s funnest bike” I’ve built and I thought it would be neat to a few old dogs (and maybe curious groms) to see a little bit of what that use to look like. I gathered some of the parts I had hoarded collected from a build I did *cough* 25 years ago. Nothing technology wise has changed faster in cycling than that of mountain bikes, but things were still pretty advanced back then.

Shimano had just come out with the first “rapid fire” (push button), shifters a year or so prior, but the dependability and (independent) adjustability of the thumb shifters were preferred by many. Plus, the XT thumbies sorta of had an extra “click” at the end and since road bikes were already running 8 speeds, tossing an 8-speed freewheel out back made for one of the only 24 speeds on the block. Speaking of freewheels, since Shimano wasn’t sharing the “cassette body” with anyone at the time, aftermarket hubs still used the old threaded freewheels. Back then Mavic didn’t produce complete mountain wheelsets, but they sold a “kit” that came with their M231 rims & Dakar series hubs, and you chose the spokes… then built them yourself. A unique piece and somewhat ahead of its time, was the Mavic bottom bracket. It was the only thing out there with external bearings at the time and rather than threading it in you had to buy a (near impossible to get) tool from Mavic and chamfer out the BB shell of the frame to have an angled surface. You then screwed the large, threaded external rings in as it became compressed into the frame. Talk about commitment! Press fit & external bearings, this thing was an early 90’s masterpiece… or nightmare depending on your perspective on awkard standards. Other tidbits include the first ever SPD pedals, Answer A-tac stem, and what kind of “fred” would I be if I didn’t have s set of Onza bar ends? The Shimano Deore DX front derailleur fell between XT & LX back before XTR existed. I left the roached out XT Derailleur with Bullseye pulley wheels in the drawer as it wasn’t very photogenic.

Raceface is a brand I’ve had a lot of respect for as back in my shop days in the early to mid 90’s, we carried brands like Santa Cruz, Ventana and Cove. We liked the “tough” stuff that would take anything. When we got our first set of Raceface I-Beam cranks (pre-Turbine), the brand and its robust Northshore attitude immediately gained some fans. Now, over 20 years later, the brand still has some deep internal roots and has continuously slayed ahead of the curve.

Back in the day, my setup was a 120mm Answer A-Tac stem clamped to a set of Hyperlight bars that were cut so short that the brake levers almost touched. Now I rock a stem less than half that length with bars that go as far as I can (now) see. I chose to go with Raceface’s Atlas lineup as it is downhill worthy, not heavy, and not super expensive. I love technical trails and cut corners pretty tight causing my hydration pack to often rub trees. I assumed these were the same width as my previous 785mm SixC bars (hey, we can’t memorize every spec), but after a couple of close pinky deaths, I realized these were 800mm. Doesn’t sound like a big difference, but it crossed the line just enough outside my comfort zone. I chopped them down to around 780mm which was money when mounted to the 50mm Atlas stem and all was good again. The Atlas bars with a 35mm bulge are stiff, but not as rigid as one might think. My carbon, 31.8mm Six bars may have a little more give, but the Atlas bars felt and performed great… and that ORANGE!

I’ve had most every generation of Raceface crankset since the beginning and I have to say their Cinch system is my all-time favorite. It’s simple, the 30mm spindle fits most standard mountain bike bottom bracket standards, (including a standard threaded one…. but they have other spindles if this one doesn’t fit), and tops it off with a direct mount chainring or spider (should you choose to use a specific 4-bolt ring), that offers a clean and dependable look. The Atlas cranks are designed for heavy duty use and though not as light as their new carbon cranks, they’re lighter than the previous generation carbon Six cranks sitting on my bench due to the 30mm aluminum Cinch spindle. The forged hollowed out crankarms keep the weight down without compromising strength. Weighing in at 733 combined grams, the Atlas Cinch system was an easy choice balancing out strength, weight & flexibility for this fun build.

Speaking of cranks, they’re no good by themselves so I had to determine what to attach to them. Chainring wise, I’ve always enjoyed Raceface’s direct mount 32t narrow/wide rings, but I wanted something a little different. I recently reviewed Absolute Black’s 32t oval direct mount chainring and oval guide they had produced by 77Designz. The Absolute Black oval ring felt a little lumpy at first when on a flat portion of the trail, but overall Absolute Black’s Oval made my ride more fun since it took the sting out of my climbs. Check out my review for a little more in-depth look, but I’m hooked as it took just the right amount of edge off the climbs without being that noticeable elsewhere.

This was a surprise to say the least. I’ve tried most every clipless pedal platform on mountain bikes including Mavic (Look style), road pedals before “SPD” type pedals even existed. When Shimano came out with the M737, the first SPD pedal with a recessed cleat, they simply nailed it. Other than not dealing well with mud, everything mechanically was great and it is still the same basic design. Since, maybe because I was comfortable with and trusted Shimano’s design, I’ve experimented with others but always went back to the tried and true… until now. One problem I had with the current XTR Trail pedals was that the couple pairs of shoes I was using wasn’t contacting the “platform” of the pedal thus not increasing the stability over the XC version. What really stood out was that I could not get the Shimano’s tension tight enough to keep my dancey feet in them. Not often, but I’ve had a couple of accidental releases… at really bad times.

While I admit no one makes a pedal more indestructible than Shimano, HT Components’ T1 fixed the two issues I had with the all familiar Shimanos. Believe me, pedal divorce isn’t easy when you’ve been riding the same pedals since before they even hit the shelves. HT Components has not so quietly pedaled their way into the market in recent years. You don’t often see lesser known companies among the major pros, but HT Components has nailed down the likes of world champs Aaron Gwin, Jerome Clementz and others. The HT T1 pedals, while not flawless, performed just how I wanted them to. They had a good platform, but more importantly, when I got a little Fred Astire on the bike (not always on purpose), I could tension them enough to hold fast when I needed them to, yet they were still plenty easy to get out of at the last second when planting a foot. I picked out a couple of minor “non-issue” flaws in my full review, but they fought their way to the top of my list fair and square.

Let’s spend a second talking about brakes. They’re not all that complicated, but yet they’ve come a long way. Hydraulic brakes take pressure applied to the lever and transfer it to the pistons in the caliper where pads are pressed into a rotor creating enough friction to stop. The trick to disc brakes is making them really light, really powerful, predictable, and most importantly, dependable. It is no secret that the last couple of generations of disc brakes from Shimano have created a pretty loyal following as they work… and work really well. One thing I had a beef with was that they came on fast & strong, but the modulation was pretty on/off leaving a little to be desired in the predictability department.

A little over two years ago, I got a brown, unmarked box in the mail. I know what you’re thinking, but when I opened it up were some loosely packaged, never before seen SRAM Guide RSC brakes and funny looking rotors. I was super anxious to try these out but I had a 2-day/7-stage enduro that weekend in Pisgah (that I was completely unprepared for). We were going up a day early to shuttle and pre-ride the course so I slapped them on and packed my Formula R0’s in the tool bag as a backup. Well, they stayed on albeit swapping out the “blued” rear 160mm rotor for an 180 that would do a better job keeping speed in check. I had never become that comfortable with a set of brakes that easily. They have the instant on like the Shimano’s but with much better feel and modulation.

Here’s my initial review, but long term, after a few sets of pads and one bleed… just because it was WAY overdue, (and is again), This pre-production set of brakes have remained flawless. I’ve ridden the latest XTR’s and still feel more at home with the Guides. While the Elixer years are still fresh in many of our minds, SRAM did their homework with the Guides. The Rotors remain the quietest I’ve run thus far, (I’ve run this set on three different frames, so they seem consistent), and perform well.

Top left corner (and in the parts pile up), I’d like to point out the Lizzard Skins’ Northshore grips. In years past, I always bounced between the all dependable Oury grips and the perfectly knurled ODI Ruffians. When I first saw what was the Oury’s and Ruffian’s love child, it was love at first site. While not a fan of the plastic plugs the Northshores come with, they use the same lock rings as ODI so I tossed some old ones I had laying around on since they accept the neat little snap in ODI caps that have yet to eject. The grips are perfect for a riding with a loose hold letting the fingers stay tacked while taking the numbing pressure off the rest of the hand till it’s white knuckle time. They have just enough cushion without being squishy to add a little more comfort over a long day, but I like to be “connected” to the bike they don’t in any way take away from that.

I distinctly recall saying to myself, “I’d never spend $300+ on a dropper seatpost that adds a whole pound to my bike”… then I tried one… “well, shit”. Now, a mountain bike without a dropper is like a hiking in a set of heels (so I’ve heard), and even the XC folks are dropping it like it’s hot. There are a few that will argue it’s not needed, but anytime you can get your COG lower like this guy, handling and stability will drastically improve.

Some time ago I had the opportunity to be a tester for L. H. Thomson’s dropper (including seeking out some faults of others). While a dropper’s benefit can not be denied, the black cloud that hung over the entire category was dependability… or lack thereof. Thomson has had a strong history of making some of the most dependable products in this industry, so developing a component that apparently everyone expects to eventually fail was no small feat. To accomplish this they researched who made the best stuff that they did not make themselves and started piecing it together. By using Norglide bearing bushings, Trelleborg O-Rings & seals, and Motul Oil combined with Thomson’s proven saddle clamps & fasteners, they hoped to develop the best and most dependable dropper on the market. While a little on the pricey side and not user serviceable, the Thomson Elite dropper has held up far longer than average. It’s also fast reacting with a little extra damping the last 15mm of travel so it lacks that “smack” at the end so not to harm any low hanging objects. Not a big fan of their knee jabbing thumb lever, but there are a lot of aftermarket options available one can surely be happy with.

Sometimes I see as much marketing in “tech” as there is actual tech when a company tries to reinvent something. Suspension, with all of the quirky technical names can be a bit overwhelming with underwhelming results at times. I have a little bit of history with suspension tuning from my motorcycle days and always felt the bike industry was lacking in producing truly adjustable suspension. The business reasons were cost and keeping it simple (so it’s easier to operate). In general, mountain bike suspension is designed to work well across a broad range of terrain and riding styles. You could always hit up the wizards at PUSH Industries and get some custom valving done (which I’ve gladly done with eye-opening results), I always thought I could have gotten closer if I could fine tune things a little more. This is where DVO’s Diamond came in. I heard it was the bees knees and one of the most adjustable forks on the market so I hit them up. While you’d have to be a rocket scientist to set this thing up blindly, they have what I think is the most comprehensive and easy to follow tech site I’ve seen. Whether you’re a suspension guru or not so tech savvy, their tech site helps you get it right where you want it. It really is an “ah ha!” moment.

Once properly set up, the Diamond was flawless. I could feel each adjustment I made and while it did take a few rides to get it where I considered it “set and forget”, it was the most gratifying feeling once it was. While the high-speed/low-speed compression settings were great in fine tuning the fork, my favorite feature was the OTT (off the top) adjustment. This took me some fiddling to get right as it isn’t an adjustment you can make on the fly without a hex wrench and shock pump. Its job is to allow you to adjust how plush the first part of travel is independently of the middle and end by externally adjusting the preload on the negative spring. For me (and other bigger riders), it fixes the lack of small bump compliance many experience due to having to add higher pressures to our suspension. The Diamond had tremendous small bump compliance while maintaining a proper platform during the latter part of the stroke when things got rough. As stated in my complete review, the only drawback was the weight, but the performance more than made up for it.

Oh, and last but not least, I stuck with my tried and true favorite SRAM X11 drivetrain. When it was first announced, I thought I’d finally quit having granny gear envy when I hit some of the most grunting of climbs. I’ve been a 1X fan for some time, but as age wears on, climbs appear to get steeper and I knew I would one day reach the end of my 36t rear cog. When I saw 42 becoming the new standard for 1X, I (and my knees) rejoiced! It shifts great, takes a beating, and has yet to let me down. While I may have really liked SRAM’s new Eagle 12 speed machinery with the 50t gear, let’s not get ahead of ourselves as I don’t need that dinner plate gear… yet, (honestly, I would have jumped all over it, but Tyler got dibs on that piece of jewelry).

So what parts would you build YOUR funnest bike with? Stay tuned as I’ll reveal the chassis I chose as a home to the colorfully fun parts next week with the final build and ride review to follow!