If bigger is better, really bigger must be more better, right? KCNC must think so with their as-yet-unreleased oversized aluminum derailleur pulley wheels. Coming in 12, 14 and 16 tooth counts, they require a special cage to fit them. They say research has shown that the larger wheels reduce drag, and these are rolling on better bearings and use drastically machined structures to create a premium offering. Overall, the package isn’t likely to save any weight over stock derailleurs since everything’s bigger and, we’re guessing, you’ll need to add several links back to the chain to keep everything working properly.

Prices, weights and availability are all unknowns at this time.

Their new floating rotor design could come in this oversized 254mm diameter. They joked that bigger, heavier (think “old guys that get fat in winter) riders need it to go downhilling, but the likely real use is big, heavy e-bikes that need the extra stopping power. They’ll also offer the post mount adapter to push your caliper out far enough to fit it.

The floating design uses an aluminum fin on a steel braking surface, pinned to an aluminum carrier. No word on pricing for these yet, either.

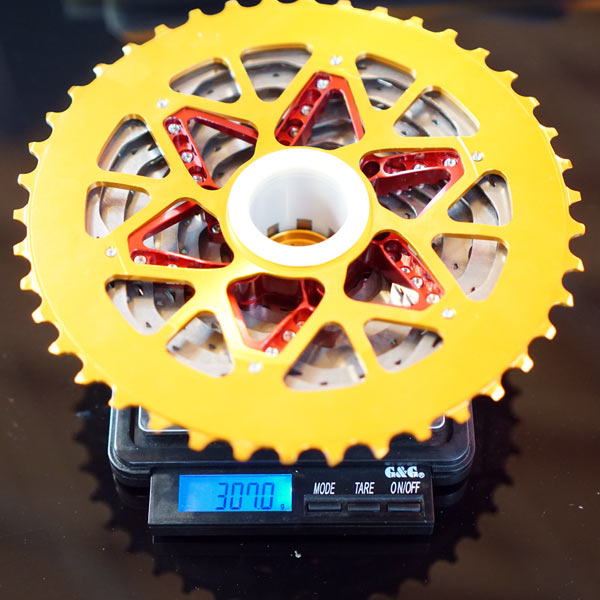

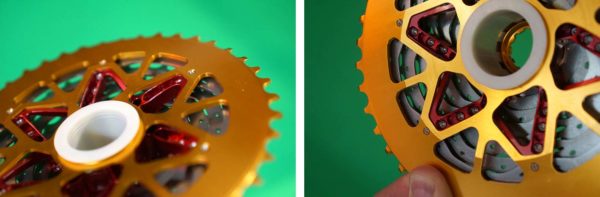

What is ready for retail is their new titanium 11-speed 11-42 cassette. The main cluster is full titanium with a 7075 aluminum large cog.

The price is €640, which is considerably higher than comparable 11-speed cassettes from Shimano, etc., but at 307g, it’s also considerably lighter.

This tops the size spectrum, slotting in on top of the full titanium 11-34 and 11-38 Shimano-compatible cassettes they already offer. The construction bolts individual 6/4 ti cogs onto a mono-block CNC machined AL7075 carrier, but this one gets V-shaped arms on the carrier as opposed to the radial design used on their other cassettes.