Lightweight has prided themselves on handmade-in-Germany construction of their fully carbon fiber wheels and, more recently, road bike frames. Now, they’re branching into automated, machine made items, starting with a single wheelset and a concept bike. The hand laid carbon wheels and Urgestalt frame will continue as premium items, but the new process will let them bring more products to more attainable price points. Before we show you those, we’ll take a look at version 2.0 of the Urgestalt road bike, which switches to disc brakes and gets a few other frame updates…

The second generation Urgestalt is designed from the ground up as a disc brake bike, not an adaptation from the original rim-brake model. Flat mounts and thru axles make it fully modern. Chainstays are asymmetric, meeting at a BB386EVO shell.

The fork is full carbon fiber, naturally.

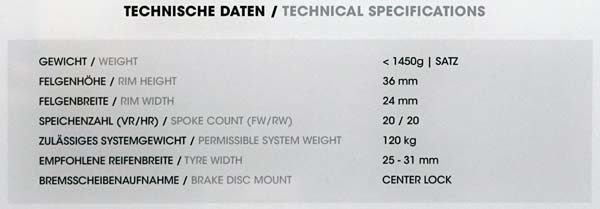

The top tube switches to a slightly sloping layout, and the 27.2 seatpost slides into a more traditional tube and clamp rather than the hidden binder bolt design from before. Frame weight is claimed at less than 850g (size 54), and fork weight at less than 380g. Max system/rider weight limit is 120kg (264.55lb).

It’ll come in 48/51/54/56/58/60 sizes and three color options (black with gray, white or red). This complete bike weighed in at just 6.2kg (13.67lb).

The Meilenstein regular and premium Obermeyer versions now come in disc brake tubulars, joining the clincher disc version launched in May. In development now, but they say they could go into production any day.

A pentagon shaped hub matches the placement of the spoke pairs, so energy from the braking is transferred to stronger points and distributed correctly throughout the wheel.

An alloy core sits under the otherwise full carbon shell, which is also pentagon shaped. This is done so that if, in the off chance, the heat from braking is so great that it delaminates the carbon from the aluminum, the shape still locks it in and stops the wheel. If it were round and things delaminated, the hub rotor would be stopped but the wheel itself could keep spinning, probably causing you to wreck. All that said, the chances of such catastrophic failure is very, very low.

All disc wheels use a DT Swiss hub internal, so it works with any axle standard simply by switching commonly available end caps. Centerlock only.

New 60mm Fernweg rear, down from 80mm, gives you the option to match the already-available 60mm front wheel.

Now, on to the machine made products…

Wegweiser means path finder, and its rim will be machine made rather than hand built.

Spokes are then glued into the rim, crisscrossed from one side of the hub to the opposite side of the rim. On their other wheels, the spokes are laid into the rim to form a single piece, as on the Meilensteins above.

They’re designed for road and gravel riding, but maybe not cyclocross, particularly since the rounded rim bed doesn’t provide a shelf for tubeless tire set up. Available as clincher only, and our measurements put the inside width at about 17.5mm.

The Project Ride concept bike uses a frame that will be machine made in segments, then bonded together. Not only will it be less time consuming to produce, but will allow for one at a time custom bikes, too. They will start with stock sizing in 2017, custom maybe 2-3 years later.

This prototype was put together in collaboration with Germany’s Fit Prototyping GmbH.

Whether or not the integrated lights make it onto the production version remains to be seen, but we’re guessing not considering there’s a target frame/fork set weight of under 1,120g.

Thru axles are included, and this prototype is using Tune’s ultra-quick design we saw last year. Other planned specs include a 27.2 seatpost, 28mm tire clearance, mech/elec shifting compatibility (and wireless, with this bike being the only one we saw at the show that had the all-new SRAM Red eTap Hydro group installed), internal cable/hose/wire routing, and BB386.