“I’m an enabler. Builders are trendsetters. I enable them.”

As probably the highest volume frame fixture maker in the world, Don Ferris’ statement just a bit of an understatement. By creating and selling solutions to problems that framebuilders face every day, Anvil Bikeworks is quietly upping the small framebuilder game, enabling these builders to build product more precisely and more efficiently, so the final product is of a much higher quality and caliber.

Anvil creates the tooling that allows these builders to effectively chase the standards that the larger industry creates, keeping product in step with the larger world. As a result, it is relatively easy for builders to keep their product relevant and compatible with the latest and greatest components and philosophies. Which is why it was very interesting to see Don Ferris rolling out a fork blade bending tool this NAHBS. By many accounts, as you look around the hall, metal forks are an endangered species- a novelty.

I wondered why someone who contributes so greatly to the continued evolution of the framebuilder invests the time and energy into making a tool for an endangered part? Don Ferris was one of my very first stops at the show so I could find out…

In order to understand the potential significance of what Anvil Bikeworks is debuting at the show, you have to appreciate how infrastructure affects builders.

Until there is a readily available or cost effective fixture solution, builders will fabricate their own solutions to problems. The talent we generally consider to be trailblazers in framebuilding, as a result, tend to be pretty creative as far as their fixturing because there is typically no easily trod or inexpensive mechanism for accomplishing the interesting things they are trying to do. It is also worth noting that this is one of those edges that mid or high volume manufacturers have, as they are more likely to be able to justify the cost of proprietary tooling over a production run.

When Anvil releases a new product, it can be transformative to the whole small builder landscape. When a single operation can be done better, more reliably, and at less expense, all small framebuilders can up their game by adding capability, allowing for higher precision in the building process, and increasing quality.

For example, with the its frame fixture and subsequent revisions Anvil was able to make framebuilding more accessible to a greater number of builders who, in the beforetimes, were reliant on fabricating their own solutions or foreign or obscure fixtures they might be fortunate enough to come across. And while people have been producing fixtures and tools for framebuilders since the very beginning of the machine, it is the ease of use, cost, and accessibility of Anvil’s product that has made it a relative household name in the framebuilding community. And it is because of all of this that Anvil is a significant factor in the growth and development of the small builder community.

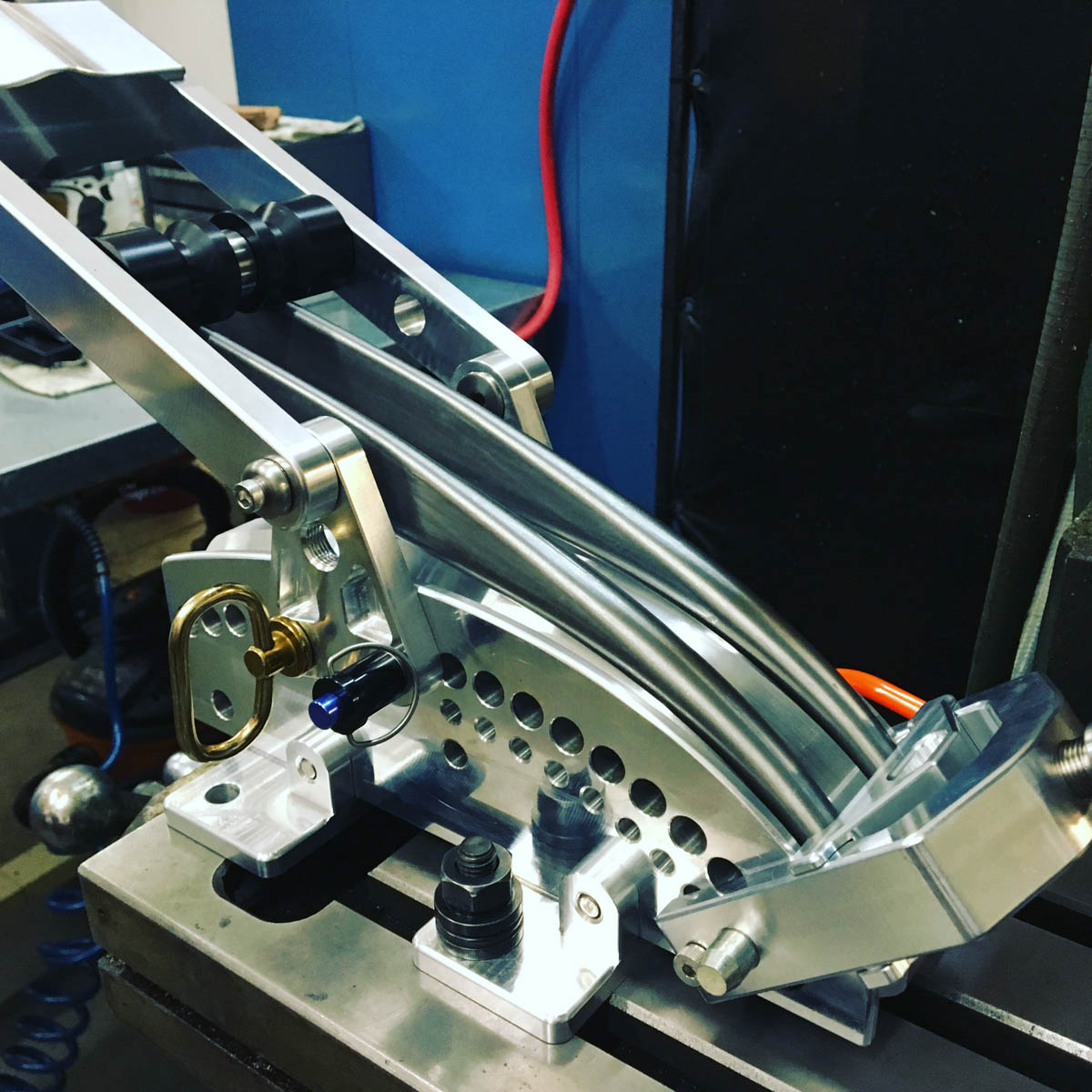

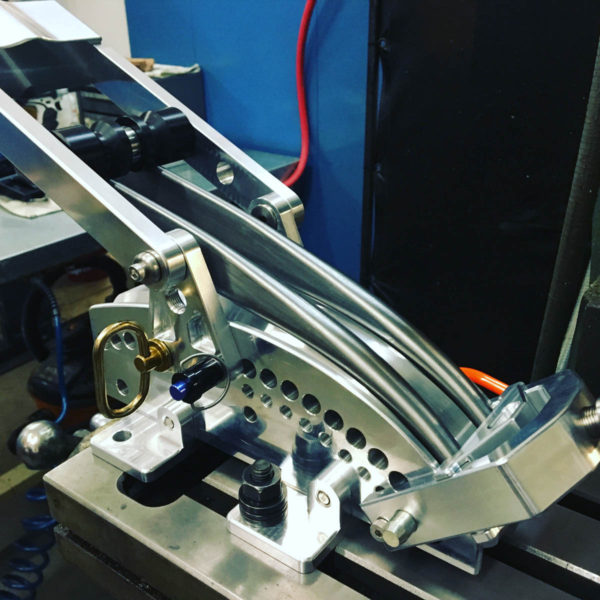

A few weeks ago, Don started leaking images of a new tool. One totally outside the realm of his current offerings. And one that, given the current climate, could have significant repercussions for just existing. “Roberto” is a tool for bending fork blades.

Why metal forks are so rare at the high end of bicycles is an interesting topic in itself. Forks are expensive to build for a variety of reasons. It is challenging to fabricate them precisely and producing them can be time consuming. When all is said and done, a really well-made steel fork can end up approaching the cost of a carbon fork, so why not “upgrade” to something with a higher perceived value?

“A fork today is considered a component rather than part of the frame. If you’re building your own fork, the fork no longer becomes a constraint.” You aren’t limited by standard fork lengths or offsets, or wheel standards when you roll your own. Plus, as Don happily pointed out regarding the feel of metal, “You can tune a steel fork too.”

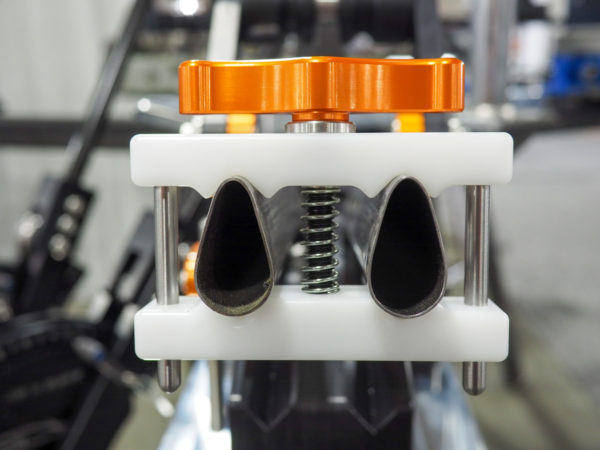

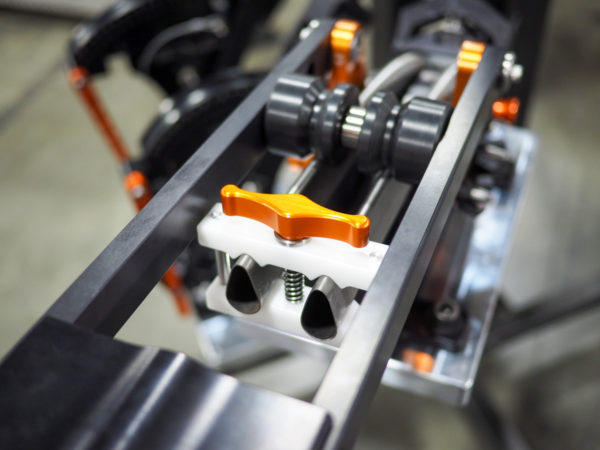

So what’s so special about the bender? For context, many framebuilders have a blade bender in their shops. The majority of the time, it is a lever that pushes a single blade into a die, giving that blade a specific curve.

The new Anvil “Roberto” bender is the first ready-made solution builders can buy that bends both blades at once. And, what’s really fun, is that due to the elliptical shape of the form and the various settings, builders aren’t limited to a type of bend and can set up the fixture to nail a specific rake value in a single go. “If you’re going to design a fork blade bender that people are interested in buying, it has to be able to bend a variety of styles and types with one bender. Some guys like that ‘french flick.’ Some guys like that classic style. Some like the ‘Italian curve.’” By moving where the blades are mounted on the curve, a number of radii are accomplished.

Plus, because of all the registration marks, if a builder finds a specific bend they like, they can document a given bend’s settings and come back to it.

So does this mean that steel forks can come back in style, better than ever? Will this NAHBS mark the rebirth of the curved blade?

Only time will tell.

The “Roberto” is available to everyone for $1250.