Stan’s NoTubes helped pioneer the modern tubeless tire system (or, at least, the non-UST version of it), and has accumulated several patents along the way. One of the key differentiators of their design is the extraordinarily low internal sidewall height. Now, they’ve been awarded a 5th patent that describes the interior shaping of the bead hook and more. They’ve also come to an agreement with Velocity about their use of Stan’s designs. Full press release below…

PRESS RELEASE: Stan’s NoTubes is proud to announce the addition of a fifth patent for their innovative tubeless rim design. Building on Stan’s original Bead Socket Technology (BST) design first patented in 2004, U.S. Patent 9,649,878 provides additional details about the interior rim shape and sidewall height of Stan’s influential tubeless rim design.

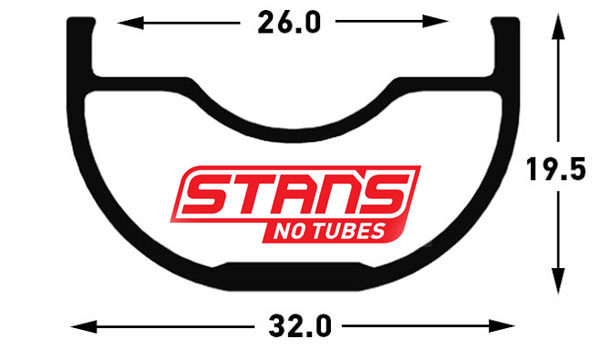

Stan’s portfolio of rim design patents describes lower rim sidewalls and how a rim’s interior shape relates to sidewall height. They also detail a specific range of dimensions for rim shape and how it interacts with a tire during inflation. Stan’s patented rim shape was designed to work with a wide variety of tubeless road and mountain bike tires.

Stan’s NoTubes is also pleased to announce an amicable agreement with Velocity regarding the use of Stan’s NoTubes’ patented Bead Socket Technology. Per the agreement, Velocity will produce their popular Blunt rims as an officially licensed Stan’s BST product. Changes will be made to other Velocity products to remove them from any conflict with Stan’s protected design. Velocity’s A23, A23OC, Aileron, Cliffhanger and Quill rims will be altered to fall outside the

scope of Stan’s intellectual property.

Velocity’s General Manager Matt Ruiter was happy to find a resolution that worked for both companies. “Velocity is pleased to feature Stan’s Bead Socket Technology on our Blunt SS model rims, providing superior strength, weight, and tubeless performance to traditional rim designs,” said Ruiter.

Stan’s NoTubes President Mike Bush said, “Stan’s rim designs have had a clear influence on the development of tubeless technology. Obviously, we need to protect investments in time and money that helped create our rims, but we also want to see tubeless development continue to improve. Tubeless technology has made bikes faster, more reliable and better handling for everyone, and we think more tubeless in the world is a good thing. We don’t want to jeopardize the ongoing development of the tubeless technology, and we look forward to creating positive partnerships with anyone currently using or looking to license our proven designs.”