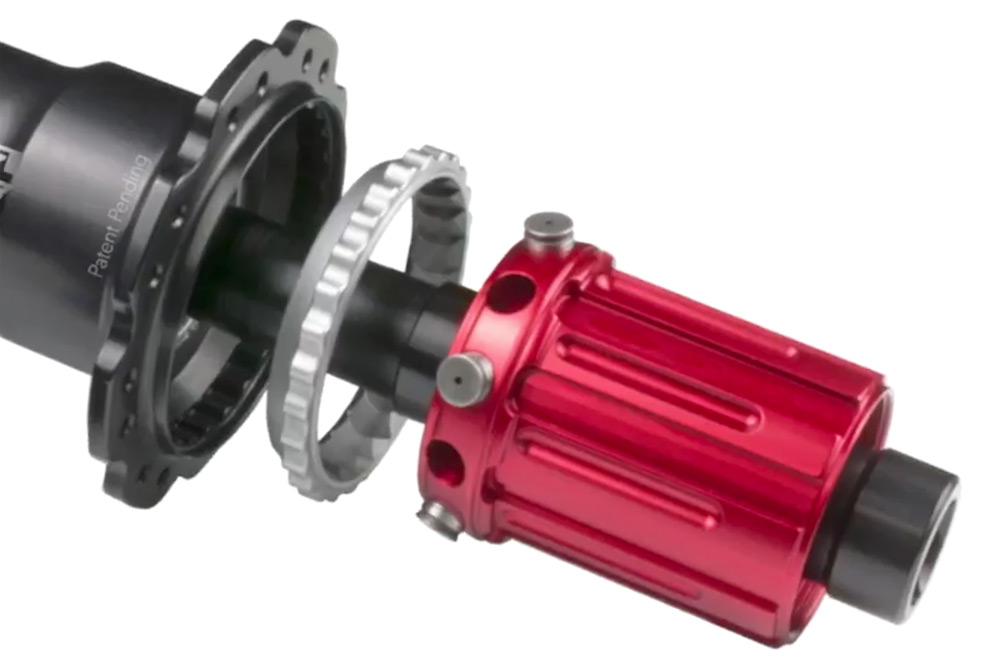

Rotor’s all new Spanish-made Rvolver hubs take a completely unique approach to engaging a freehub body with the hub. Most basic designs use flat, spring-loaded pawls to ratchet along & grab a toothed ring in the hub to transfer power, but Rotor wasn’t satisfied with that standard solution’s friction. Instead the Rvolver uses a series of cylindrical posts set at an angle into the cassette body and an engagement ring that moves out-of-the-way when freewheeling to cut down on drag even more…

The interface of those cylindrical pawls & the precisely machined floating ratchet ring are what really set the hub design apart. And for now we have just this one image of how they look from inside the hub. The cylinders are not set straight into the alloy body. But instead they sit at an angle, offering less friction when freewheeling, but plenty of bit when you put power to the pedals. Then their round shape means that when you coast, they push the engagement ring away into the hub shell a few millimeters where it is out-of-the-way from friction a bit more. Pedal forward and the top edge of the cylinders grab the tooth ring and pull it back into line for full power engagement. The totally unique design cuts down on internal friction and apparently helped Rotor keep the hubs very light as well.

The Rvolver hubs offer 25 point of engagement between what looks like 5 cylindrical pawls and the floating toothed ring to connect every 14.4°. Looking at that cassette body, it may even be possible to add 5 more pawls to cut that engagement time in half.

Rotor has developed the system into two basic hub sets – rim & 6-bolt disc brakes. That means they have you covered for everything from classic road to road disc to mountain with Boost spacing (you can build standard MTB on the road disc hubs we presume). All of the hubs get extended hub flanges optimized for either standard or 2:1 lacing, all with J-bend spokes and sealed bearings. The 7075 machined alloy hubs are all made in-house by Rotor at their factory just outside of Madrid, Spain.

Road rim brake hubs

The QR axle road rim brake hubs feature 16 or 20 hole front and 24 hole rear drilling. Shimano splined only, they weigh in at 89g/198g and will sell for 147€/328€, respectively.

Road disc brake hubs

Road disc brake hubs are also Shimano cassettes only and get 24/24 lacing with standard 12mm thru-axle setups, or a conversion kit to go 15x100mm up front. They weight 119g/230g and retail for 155€/344€, respectively.

Mountain Boost disc brake hubs

And mountain hubs get 28 or 32 hole lacing for both front & rear hubs, only in Boost 15×110 & 12x148mm spacing. Front hubs weight 112g, while the Shimano rear is 238g & XD rear weighs 244g. They’ll also sell for 155€/344€, respectively.

All of the new Rvolver hubs will be available through regular Rotor dealers starting in October 2017.