“What’s the most interesting thing you’ve seen at the show?” That’s a question we get a lot while we’re hustling through the rows of booths at a trade show like Interbike. More often than not, my answer consists of a sort of glazed look over my eyes as I can barely remember the last booth, much less the entire show. But every so often, something catches my eye that really sticks out.

This time, that something was ‘Standard 21.5’ – a wild new drivetrain concept from the brilliant mind of Veso Mandaric. Named after the diameter of the rear axle, Standard 21.5 has a lot going on – it’s far more than just putting the cassette outside the frame. Still in the very early concept stages, Veso said that he was literally still hand making parts to get it together the Tuesday before the show. But the proof of concept was enough to garner the attention of much bigger drivetrain players like Shimano and SRAM, so it seems like it could end up as more than just a wild concept.

The design starts with two crazy stout box section chain stays, which are positioned to be narrower than your average 142 x 12mm spaced road frame. Much of the concept centers around drastically increased drivetrain efficiency so Veso says this part of the design is important for power transfer. While the half prototype is mocked up in aluminum, he expects the final design to be made in carbon – including the axle. That’s one of the reasons the axle is so big, as it can be made from carbon and still be lighter than a comparable 12mm axle.

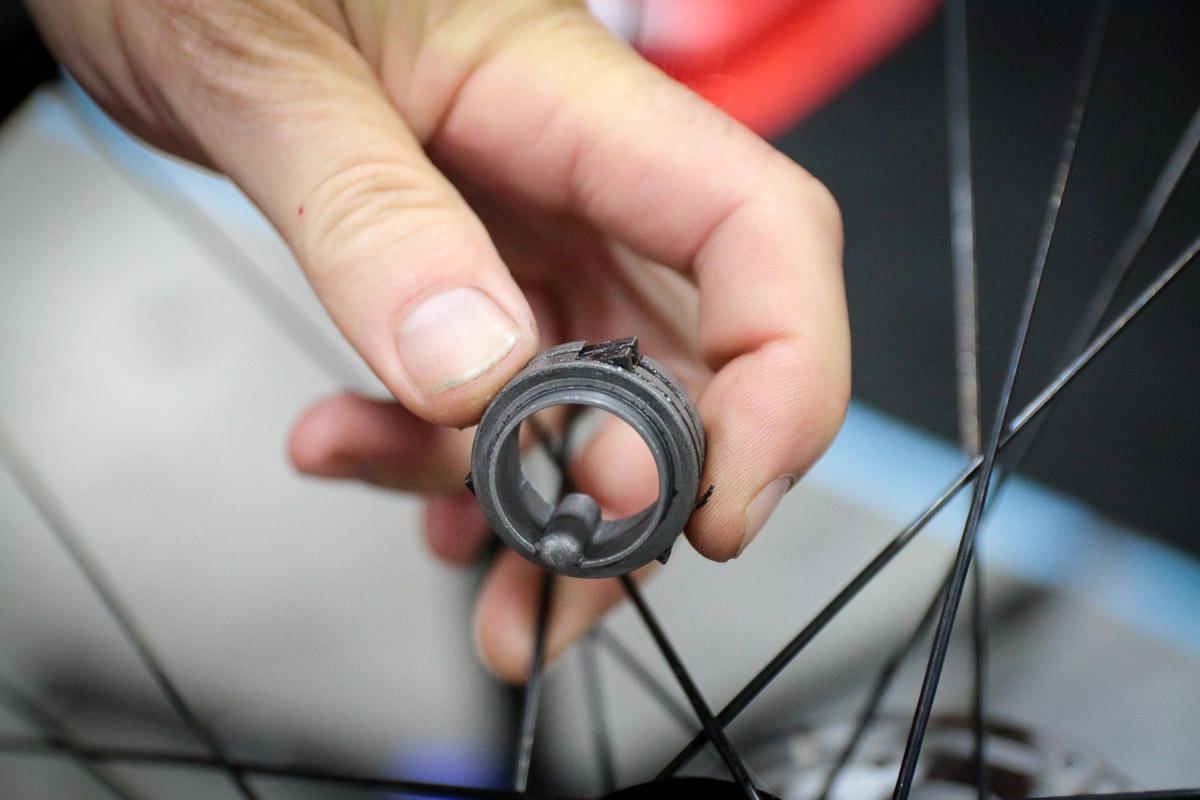

This is even more important than usual, because one of the most peculiar design elements of Standard 21.5 is that the axle actually spins along with the cassette. To make that work, the cassette is essentially fixed to an XD free hub body that is captured in the right dropout of the frame. The free hub is mounded inside of a bearing, and a hand made C-clip holds it in place at the moment.

The axle has a keyway that locks into the driveside frame bearing, but also into the prototype free hub mechanism inside the hub. Currently a unit from REAL Components, the free hub engages the hub shell as normal, but this time the axle spins along with the cassette and the cranks.

For the sake of the prototype, Veso used a standard 142 x 12mm hub that he removed the free hub body from and modified it to fit the 21.5mm axle. In his mind, the finished axle may actually be triangluar with rounded lobes since he says three points of contact on the inside of the bearing are adequate. That would also allow the free hub to float on the axle rather than rely on the key. The finished version would also allow for new hub designs which could potentially result in stronger wheels.

One of the hidden benefits of the system is that the bearing spacing is wider than your typical road wheel, especially given the fact that there is a bearing outside of the driveside frame member. Vero says that this has the potential to offer greater stiffness and power transfer over a traditional design, while also opening up the possibility to fitting more gears into the rear cluster.

Perhaps most importantly, the design seems to have impressed a few important people when it comes to the design of the rear derailleur itself. Calling it a mid mounted design, the current derailleur shown as a placeholder won’t actually work with the bike. But a derailleur that was specifically designed for it could offer better and more precise shifting since it offers better chain wrap, and would use more of a horizontal movement that wouldn’t be fighting against the spring tension of traditional derailleurs. This is the part of the design that makes it all seem like a production bike could be a ways out, but Veso says he is currently trying to figure out a way to make it work using pieces of existing derailleurs.

For those worried about crashing or the exposed cassette, the finished design may have a larger protective disc on the outside integrated into the spindle. Also, the non drive side will likely have a saftey pin that engages once the derailleur is in place as a guarantee that it won’t back out accidentally.

If that wasn’t enough, in order to offer huge tire clearance, Veso cut a BB30 spindle in half on a lathe, and then welded it back together in order to make a spindle that would work with a 105mm bottom bracket.

And Standard 21.5 wasn’t even the only wild concept at the Mandaric booth – they also had this clever take on the threadless headset and stem. Not much has changed in the design of threadless headsets and stems in years, but that might change if Veso has his way.

Instead of just two bearings on the bottom and top of the head tube, Veso’s design uses three – with the third bearing above the stem. He says that this increases strength and stiffness of the system, and should eliminate the potential for carbon steerer tubes to shear off underneath the stem which has happened to a few racers in the past.

More importantly, it would allow for a complete redesign of steerer tubes and stems as we know it. Vero envisions a D-shaped steerer tube, with a corresponding D-shaped stem. The shape would prevent the stem from ever going out of alignment, and since the upper headset design would clamp down on the system, he imagines a stem without any bolts on the steerer clamp. This would potentially allow for a much lighter stem design, though there’s the obvious addition of a third bearing in terms of weight.

More than anything, even if Veso’s creations don’t make it to production, they were a refreshing dose of outside-the-box thinking. I have no idea if we’ll see these ideas make their way to production any time soon, but we’ll be following Veso Mandaric’s work very closely from here on out.