When it comes to fork, it’s pretty easy to know what you’re getting should you upgrade. Just get a tapered steerer and match the axle type and the travel and you’re good to go.

With shocks, it’s a little trickier. OK, a lot trickier. There are more measurements to account for, and those aren’t always easy to determine. You’ll need to do a little research, or pull out the calipers and other tools. Here are the three basics and how to measure them…

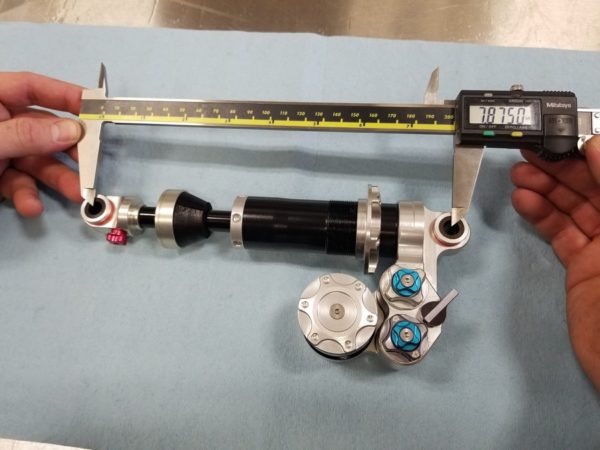

EYE-TO-EYE

The eye-to-eye measurement is the total length of your shock, as measured from the center of each mounting bolt hole on either end of the shock. Which is among the easier things to measure, unless your shock’s mounts are rotated 90º from each other. Or it bolts directly into the yoke from its end rather than pivoting on a bolt and bearings. But, basically, this measurement refers to the effective overall length of your shock.

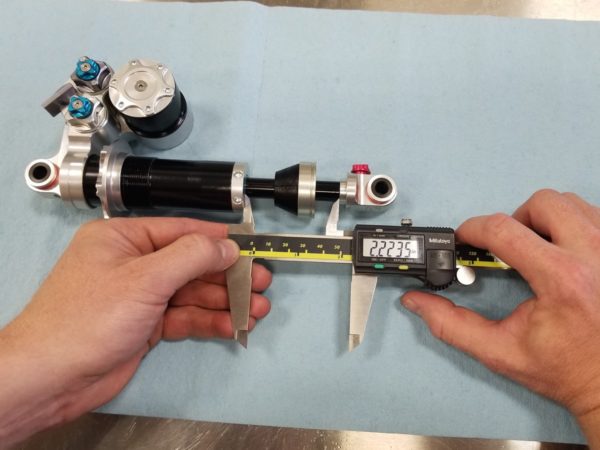

SHOCK STROKE

When it comes to shock stroke, which measures the total distance the shock compresses from fully extended to fully compressed, it depends on the type of shock you have. On coil shocks, it’s quite easy, says PUSH Industries’ Darren Murphy. Simply measure the exposed shaft. That means the smaller shaft that slides into the main body of the shock, which sits under the coil…so you’ll likely need to remove the coil to get an accurate measurement. So you’ll need to mark it’s location so you can get it back to the right preload setting.

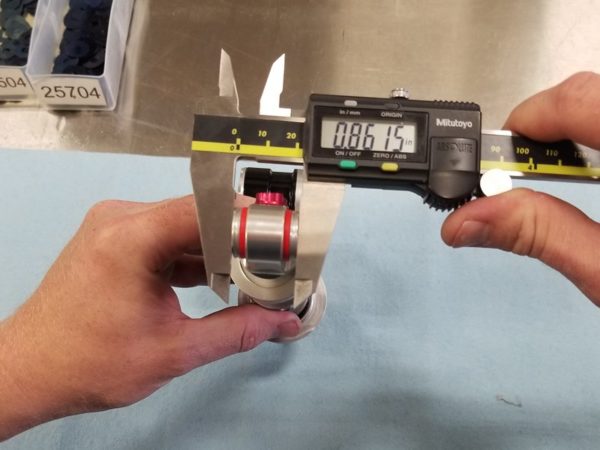

But on air shocks, it’s not as simple. Technically, the “air spring” part of an air shock sits over the piston, just like a “coil spring”. The tricky part is that the air canister covers it. A lot of models use internal spacers to control the stroke. So you need to take the air can off to properly measure stroke by measuring the internal piston.

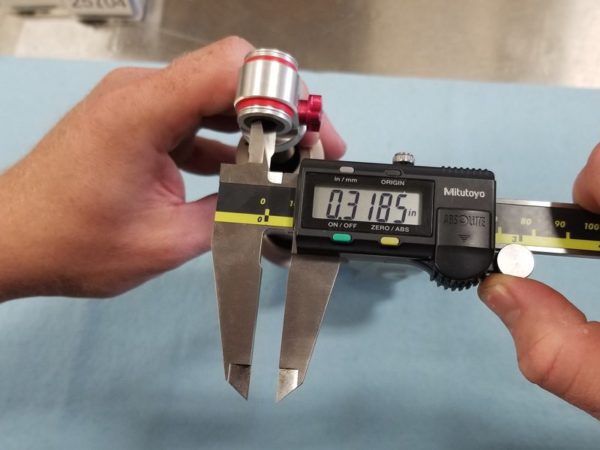

MOUNTING HARDWARE

The mounting hardware needs up to three measurements – bolt diameter, bolt length, and mounting width. And these might be different on either end of the shock. If you’re upgrading just the materials that sit between the shock and the bolt, you’ll need to know bearing or bushing width, diameter and thickness, too. Many times these are Igus bearing bushings, and they can sometimes help you find the right part. Or…

You can probably call or email your bike’s manufacturer to get their specs (if they’re not already listed on their website), or you can ask the suspension manufacturer which model you need as they’ve probably got a list, too. Regardless of which one you ask, it’s a good idea to inquire about the shock’s tune, too, as most every bike now has a custom tuned shock based on the frame’s leverage ratio and other parameters. Or, you know, have your local bike shop do that for you and order through them.

Huge thanks to Darren at PUSH Industries for helping us level up the answers and images this week! Hit that link to check out their ElevenSix coil-over shock to upgrade your long travel enduro or DH bike!

The fun never ends. Stay tuned for a new post each week that explores one small suspension tech, tuning or product topic. Check out past posts here. Got a question you want answered? Email us. Want your brand or product featured? We can do that, too.