Welcome to Tire Tech, Bikerumor’s mostly-weekly series on bicycle tires. Like our Suspension Tech and AASQ series, we take your questions about tires, whether it’s road, cyclocross, fat, plus, gravel, or mountain bike, and get answers from the brands and people behind them.

Depending who you ask, designing mountain bike tires is either a science, a craft, or some sort of voodoo magic. It requires knowledge of rubber compounds, knob shapes and how to arrange them in the ideal pattern. And there’s not just theories about how those come together, but variants of all that for different disciplines, trail types, ground conditions, and riding styles. For this post, we’re starting off with mountain bike tires and the basic knob shapes, why they’re different and how they affect performance.

How the rubber meets the trail

How a tire grips the trail is determined by things like vertical loads, friction coefficients (Ff = Cf x Fv), adhesion values, rubber deformation, viscoelasticity, and—mechanical keying. Those factors are made complex by other variables like the riding surface, rider style, and air pressure.

According to the tire experts at WTB, just calculating the effects of air pressure on tread designs is challenging as tire rubber is non-isotropic, meaning its physical properties do not have uniformity. There isn’t a good way of calculating the effects of pressure on rubber. Computer models and real-world riding dynamics don’t always align. For their designers, experience has allowed them to learn from past successes and missteps.

That’s largely how most mountain bikers select tires. After a while, you learn what works and what doesn’t. But you may not grasp why. As it relates to tire knobs it helps to understand what makes a given tire effective in certain conditions.

Tires are designed to leverage a principle called mechanical keying. It’s best described as the interface between tread features and imperfections in the trail surface. Imagine an individual tire knob as it catches against the edge of a rock. The lugs mechanically exploit edges, holes, and other surface textures to give each raised chunk of rubber firm purchase. The shapes, depth, firmness, and spacing of the knobs influence how well they interlock with the trail. Because not all trails and riders are the same, knobs also come in a wide range of shapes and sizes.

Mountain bike tire knob types

Tapered knobs are typically used for wet and muddy conditions. By tapered, we mean thicker or larger at the bottom than at the top. While tapered knobs lack sharp edges, they self-clean as the tire rotates. A clogged tire is heavy and has the traction of a greasy slick. When paired with large voids, tapered knobs stab at the soft ground for optimal traction. But they have to be able to penetrate into the trail surface to be effective.

Ramped knobs are common and used on a wide range of tire types. Although squared lugs offer excellent edging properties, they also add rolling resistance. Ramped knobs are often applied to provide superior rolling efficiency on one side of the knob while providing a large vertical edge on the other for improved braking. They reflect the disparity between the aggressive forces of braking and the somewhat mild forces of acceleration.

Small and Micro knobs are prevalent in cyclocross, gravel, and cross-country tires. These shallow and compact knobs are used to reduce tire weight and improve rolling efficiency, albeit at the expense of traction in loose surfaces. They also allow the tread to flex more uniformly with the tire casing.

Darts and chevrons are pointed or angular knobs arranged to provide large lateral edge surfaces. Darts are typically used on front tires where turning proficiency is the chief concern. With their pointy forward edge, the trailing edge is large and improves braking control. The nuances of wheel-specific tire designs is also a topic we’ll tackle at a later date.

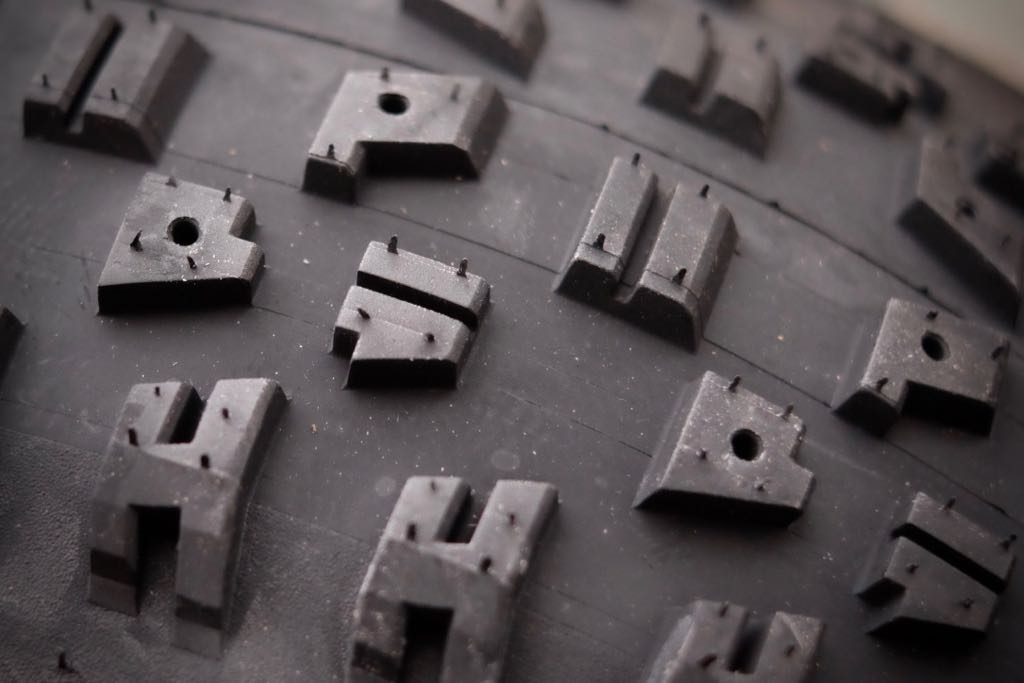

Siping isn’t a knob, but a treatment applied to flexible surfaces of all kinds ranging from skateboard shoes to auto-racing tires. Best described as tiny zig-zag cuts, they’re designed to open like little jaws when the tire is flexed. The sawtooth cuts elongate the edge and give it a multi-directional grip. The miniature edges add friction and help to expel water from between the tire and ground. Siping can also be used to force knobs to deform in specific ways, allowing the designer to encourage tires to perform in more controlled manner under hard cornering.

Although siping has been used on road and touring tires for years, it is relatively new to mountain bike tires as seen on the Terrene Cake Eater in our most recent Tire Tech segment on plus-size tires and on the Schwalbe a couple images above. The holes in the lugs seen below are designed to accept metal studs for bolstered traction on slick ice and snow.

Cuts and grooves act like large sipes (also sometimes called siping) and are used to add extra edges to a tire lug. They also give it more flex in its outer aspect. It’s a way of fine-tuning the desired dynamics of the knob for better braking, turning, and accelerating.

Making the most of the knobs

It’s not enough to just design the right knob and slap it on a tire. Pairing it with the right rubber compound is essential as it lends the necessary flex or support for the lug to do what it was designed to do. Some compounds are chosen to give the knobs enough flex to conform to the trail. Too soft and it will flop over under weight and force. If it’s too firm, it may chip or wear prematurely.

Other design considerations involve mixing and matching knob types and arranging them in a specific pattern. Knob patterns are tricky to design. The orientation of a knob alone has a significant effect on tire performance. The foundation of the tread base and tire casing also contribute to the effectiveness of the lugs. Pronounced side features will require a stout foundation (and sometimes even buttressed supports) if they’re to retain the rigidity needed to stand up to hard cornering.

In upcoming installments of our Tire Tech series, we’ll dig into the nitty-gritty of how designers use knobs within a specific pattern to create tires with certain ride qualities for certain types of riding.