Ready for another battle of the wind tunnels and white papers? There’s a new wheel company in town, and they’re aiming straight for the top with their first wheel – the WAKE 6560. Started by a group of elite rowers who have found their passion for cycling, Princeton CarbonWorks is the result of four years of work from self proclaimed “Princeton and Boston University Uber-nerds.”

It’s hard to not immediately think Zipp NSW Sawtooth when you see the WAKE 6560, but Princeton CarbonWorks says that they started with a blank page and settled on the sinusoidal design through a lengthy design and FEA testing process. The design is said to offer a constantly varying trailing edge which offers lower drag and reduces the effect of vortex shedding. Like the name suggests, the rim varies from 65mm to 60mm deep and includes 24 sinusoidal oscillations. The rims are also tubeless ready with an internal width of 18mm, and 26mm external.

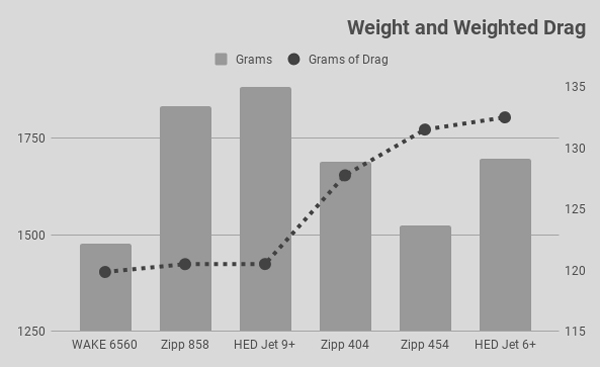

In their own wind tunnel testing, Princeton tells us that the WAKE 6560s supposedly produced less drag than the Zipp 858, yet are lighter than the Zipp 303. If true, that becomes particularly impressive given that they’re also less expensive.

Available in both rim and disc brake models, each are built with standard or Chris King hubs as an upgrade and Sapim CX-Ray spokes with Secure Lock nipples. The rim brake model uses a 16/24 spoke pattern, though 24/24 is available on request. The disc brake version is only available in 24/24. Weights are given as 655/840g for standard hubs or 675/850g with CK for the rim brake, and 705/815g standard or 745/850g CK for the disc brake version.

Shipped with skewers, tubeless tape, valves, padded wheel bags, and Swissstop Black Prince pads (rim brake model), WAKE 6560s start at $2,400/$2,600 per set with standard hubs (rim/disc), and bump up to $3,200/$3,400 for the Chris King equipped versions. We’re also told that a 30/35mm deep version of the WAKE rim is on its way in the near future so keep an eye out for that.