In a world of incremental gains, getting a big improvement in speed and acceleration is just that: Big. Syncros takes the most important place to save weight and does it in a big way with the new Silverton SL full carbon wheelset.

The wheelset is designed as a system, far more so than designing a rim around separate spokes and hubs. The one-piece design allows them to tune everything. Past full carbon wheels have used larger spoke wings (think three- and six-bladed aero wheels). But those could ride stiff, where a traditionally spoked whee can feel lively and actually enhance the ride. Their solution? A middle ground, offering the stiffness and lightweight they wanted but in a package that rides like a good wheel should.

The result is this 20-spoke wheel with a claimed 1,250g weight. Compared to a regular wheel, they say it’s 30% stiffer laterally and 100% stiffer torsionally. That means instant acceleration not just because it’s super light, but because there’s no torsional flex wasting your valuable energy. It also means snappy handling that should go where you point it. With carbon, they could make it as stiff as they wanted, but they tuned it to ride well while also staying well within the limits of the material and rider comfort levels.

Designed around 29×2.25 to 2.4 tires, they have an impressive 26mm internal width and 31mm external. The hookless internal rim surface is completely closed, so they’re tubeless ready without adding tape or weight. Perhaps more impressive is that the rim itself is only 286g. And the spokes? Just 80g per wheel.

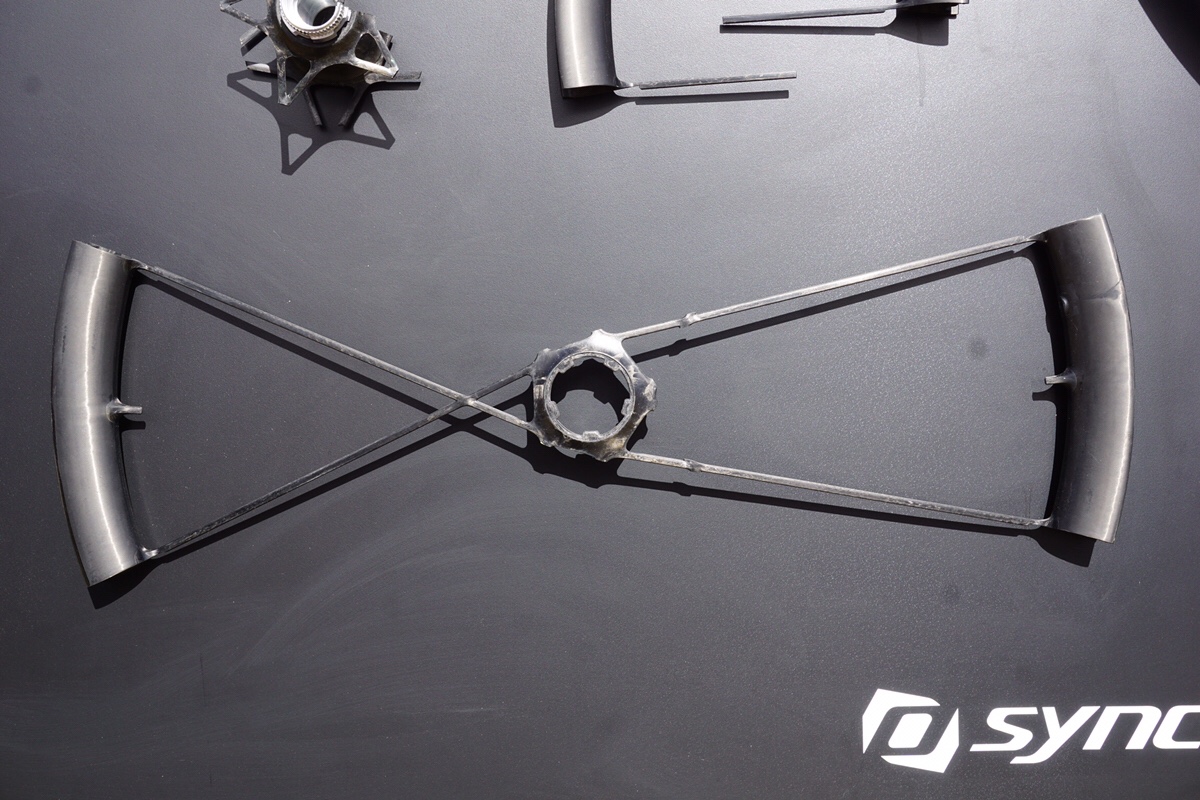

Inside are DT Swiss 190 hub parts with ceramic bearings. They’re Boost spaced, naturally, and use Centerlock rotor mounts. They use equal spoke “flange” height, and the spokes cross each other from side to side…slightly.

At first glance, the spokes appear to run to the center of the rim. But they actually run slightly off center, with the spokes leaning to the right side of the rim heading to the left side of the hub. This increases lateral stiffness and also allows them to use a higher modulus (lighter) fibers. Yet they’re 35% more impact resistant than steel spokes, thanks to a three-layer construction. And if you did break one, chances are you could still ride out of the trail.

Another aspect of the design is keeping the spokes’ fibers working correctly is creating tension in the spokes. The flanges, as molded into the wheel as a whole, are set narrower than the hub shell that’s molded in later. By stretching it, it maintains traction in the fibers and reduces how much compression they’ll see, which is better for the longevity of the fibers.

Part of the challenge in making this was designing the mold. Originally it required a 31-piece mold, but in two years of development they got that down to 8 pieces, which is what makes it possible for them to mass produce it. Retail is $3,499, and they should be available in September. Max rider plus bike system weight is 130kg.