When asked why they had not designed a disc wheel before now, Specialized’s Chris Yu responded with a surprisingly simple answer. There were already a lot of great disc wheels on the market. If they were to make their own disc, it would have to hit a few key metrics. With input from a few of their sponsored riders like Fabian Cancellara, they started to frame their design targets. Chief among them were the usual criteria for aerodynamics, but also for stiffness, compliance, and weight was a major concern.

Although it was proven weight was not as critical to speed as previously believed, riders like Cancellara stuck to their guns and said the low weight had a positive feel and feedback. It wasn’t an easy benchmark to hit, but the new Roval 321 is the lightest manufactured disc on the market at 1,005 grams.

To achieve their aerodynamic goals the team relied heavily on their Win Tunnel, which just celebrated its fifth birthday last week. The Specialized aerodynamics team created a wheel with the widest possible shape to help retain air contact as long as possible. The design was optimized to accommodate a 26c tire, which also improved compliance. The drive side has a unique, and subtle, recessed pocket to accommodate the derailleur in its most inboard position.

After carefully evaluating the rolling resistance values between tubular and tubeless clinchers, the decision was made to create only a clincher variant of the 321. The design is tubeless ready out of the box.

The new wheel isn’t all about speed and efficiency. The valve hole is large enough to accommodate a standard pump head and fits a 60mm valve stem. Riders using deep section front rims now only need one spare tube for both wheels. A hardcover snaps over the valve hole in lieu of less sophisticated sticker solutions.

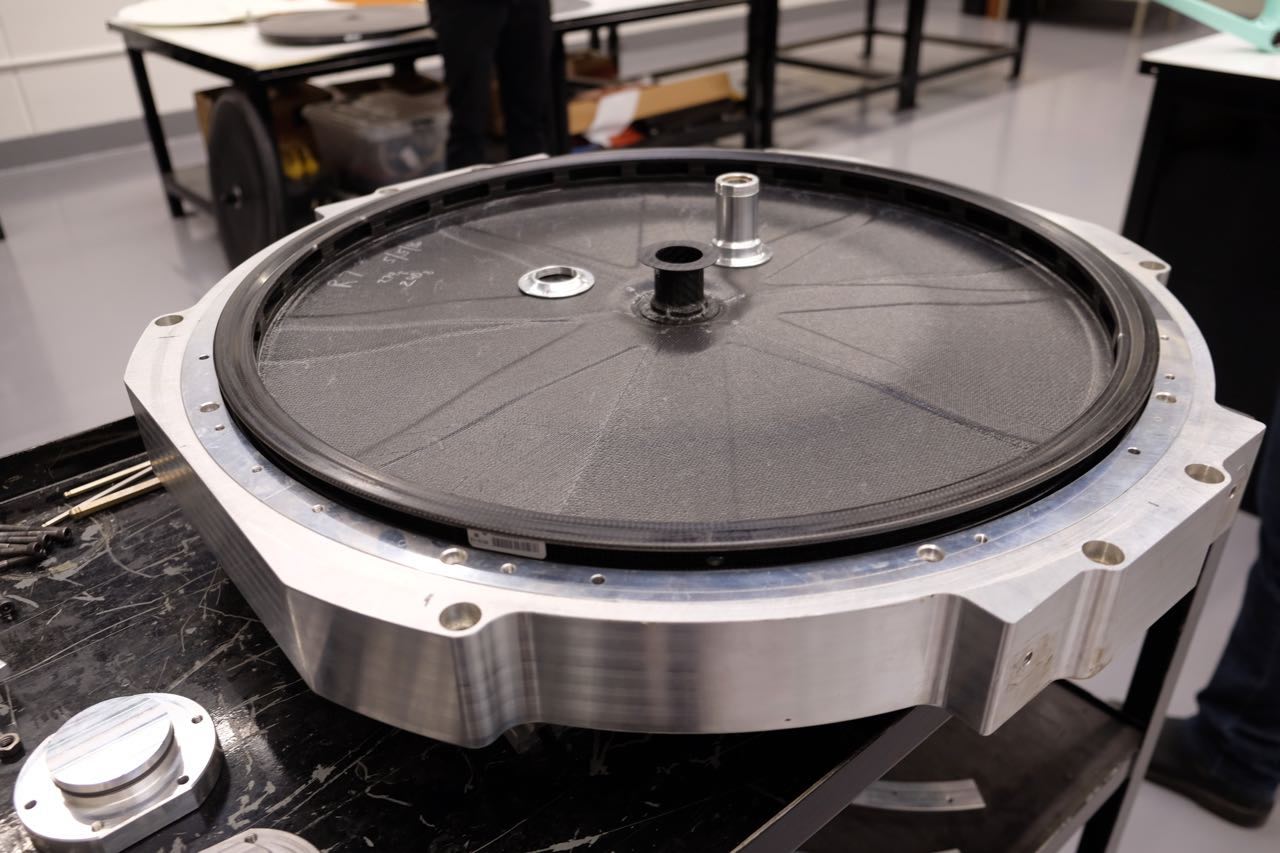

To achieve their aerodynamic, weight, rolling resistance, and stiffness objectives, the Roval team leaned on the comprehensive resources at the Morgan Hill facility. That includes their advanced machine shop, new carbon fiber lab, and other testing tools. They now use advanced imaging machines to inspect the internals of every component. No design, engineering, or testing stone is left unturned.

Central to the process is their ability to now create the tools and processes by which Roval 321 wheels will be made by manufacturing partners overseas. They have the resources to construct special tooling components which simplify the manufacturing steps with devices used to help shape the wheel lenses, facilitate the joining of the rim, and serve as the jig for any necessary drilling. They can design, test, and fabricate test wheels while simultaneously creating the exact manufacturing process, on-site, that will be used to produce all of their wheels going forward. Many of the first wheels used by sponsored riders during the last year were manufactured start-to-finish in the Morgan Hill office.

It’s that holistic approach from prototyping to manufacturing that allowed the Roval 321 to hit its design marks in such a short amount of time.

The 321, named in part after the iconic countdown before every time trial, is available in rim and disc brake versions with a retail of $2,500. Some of you may have noticed Specialized does not currently have a disc brake equipped time trial bike in their quiver. That speaks to their desires to build for the overall market but certainly hints to a reboot of the Shiv.