What if you wanted to completely rethink a bicycle drivetrain to have less drag, less weight, and take up less space? That’s what CeramicSpeed has done with their new Driven drivetrain concept, relying on a pair of roller pinions on a carbon driveshaft mated to a completely flat cassette.

CeramicSpeed’s tests show that a typical Dura-Ace drivetrain’s peak efficiency is around 98%, and a CeramicSpeed optimized version of that is 98.5%. We truly are talking about incremental gains. The new Driven system achieved 99% efficiency in the same test. When you start adding in things like chain lube degradation and cross-chain friction, things get worse for the traditional drivetrain. And those peak numbers? That’s at an average power output around 500 watts. If you’re not putting out that kind of power, the numbers get a little worse. At 200 watts, DA is around 96.75% and the optimized version is 97.75%. The Driven system is up at 98.75%. Putting the numbers into another format, they say at 250 watts, Driven has 32% less friction than the CeramicSpeed optimized DA drivetrain, and 49% less friction than a stock Dura-Ace group.

If the drag numbers don’t impress you, there are other benefits, too. It’s potentially far more aerodynamic, and it’s definitely lighter. The power meter can be integrated into the drive shaft, and the gear combinations are nearly endless. The cassette can add as many speeds as they want (within reason, of course) because it doesn’t need additional width to add more speeds.

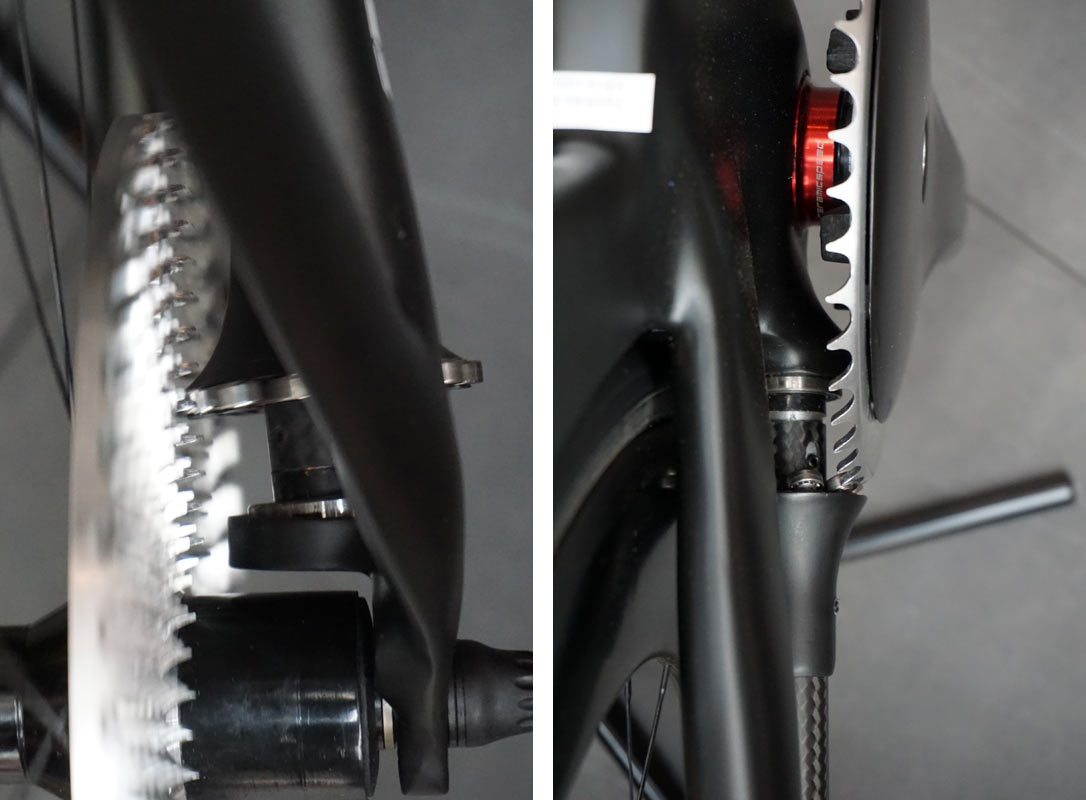

The roller pinion slides fore and aft to shift gears.

The fixed front pinion can be designed to move, opening up the opportunity for a double gear set up front, too. This concept is limited to a single front cog, though.

This one’s left open to show how it works, but it can easily be placed inside a cover, or possibly even inside a chainstay, to protect it from the elements. As is, it requires an elevated chainstay, and therefore a custom frame. Should it make it into production, frame builders would be required to build the bike specifically for this. Don’t hold your breath…the concept has only been in development for nine months and still has a few bugs to workout.

There’s also the opportunity for using different materials to save more weight, and angling the teeth and/or bearings to further optimize its motion. Even double-row bearings could be implemented.

For now, it’s purely a concept, but this is how great ideas start. Well done, CeramicSpeed!