Leave it to the Black Forest residents at Tune to drive real technical innovation, while also shedding grams. The German lightweight specialist had several new products in various stages of development to share at Eurobike last weekend, highlighting new ways to look at their core carbon and aluminium manufacturing techniques

Tune carbon & alloy Prototypes and Concepts

A few of the most innovative concepts are still in prototyping, currently being subjected to Tune’s rigorous testing procedures at the Black Forest Test Centre. But Tune’s engineers have one proto almost ready for production, and one already for sale….

First up, a heavily engineered and lightweight self-adjusting thru-axle. The prototype concept under development is designed to eliminate all bending force that may be applied to the axle. Despite high-end modeling tech and the precision engineering involved in frame design and manufacture, it is still very difficult to build frames where the rear axle alignment is perfect. Measuring (and maintaining) parallelity requires some very expensive kit which many manufacturers just don’t have.

Using spherical contact points and a spherical washer, load can be applied homogenously throughout the axle as it self corrects any misalignment. With the absence of bending force, Tune have been able to reduce material throughout the axle. Weighing in at just 23g, it is 7g lighter than the lightest competitor on the market. An additional benefit to the self-adjustment concept is that a significantly reduced torque is required to tighten the axle sufficiently for riding.

Usually, an axle needs to be tightened to around 20 Nm to cope with the bending force, yet 5 Nm is all that is required to tighten this axle, and it can be done by hand with the spherical closing nut. Tune are yet to decide on whether or not to pursue development of this axle and if they do, it is likely to be targeted at OEMs.

Ultra-light Tune Skyracer injected carbon saddle

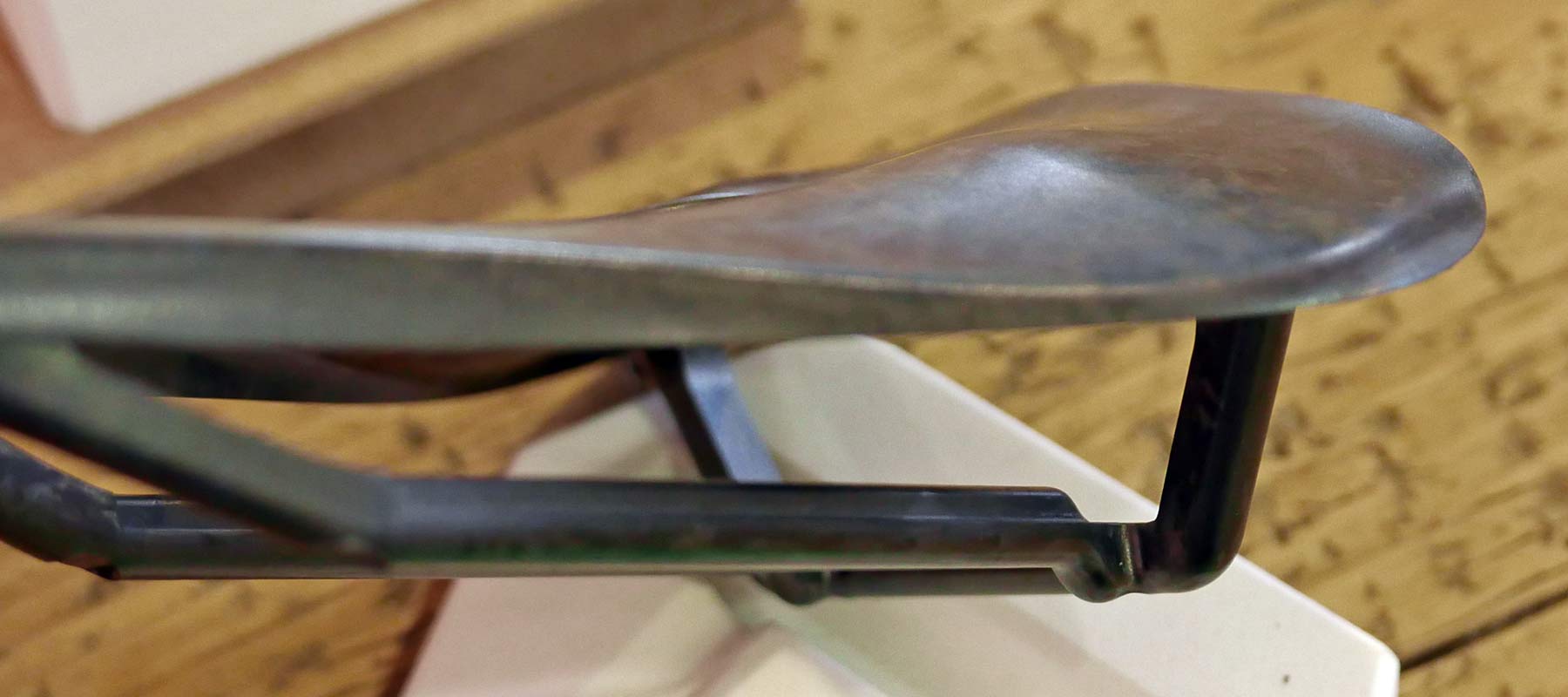

Secondly, a new one-piece super lightweight carbon saddle is being made using tech adapted from the aircraft industry. Manufactured using a complex, multi-part carbon compression mold at an unusually high 400°C temperature and 300 bar pressure.

Designed with ergonomics in mind, the Skyracer saddle features two stepped seating positions to choose from. It also uses a unique rail profile that is round overall to fit with the most seatpost head designs, but cuts away extra material that Tune says didn’t add any strength.

Interestingly, the saddle is also fully recyclable. Most carbon components use thermoset resins, which can be recycled to a certain extent, first being broken down into much smaller fibers that can be reconstituted into new products; however, the quality of the carbon fiber is severely reduced after this process. This one-piece saddle though is a thermoplastic, which can then be reshaped again under that extreme heat & pressure.

Weighing just 69g for this prototype, the Skyracer will sell for around $380 and will include a refined 3D printed nose cap that adds a bit of color and protects thighs from the carbon shell’s edge. While the new saddle has no padding, Tune expects to utilize the manufacturing techniques to make their other saddles even lighter & fully recyclable in the future.

Black Burner 29 Textile Edition, 999g MTB wheels

Thirdly, the Black Burner 29 TE (Textile Edition) XC mountain bike wheelset is pretty wild, but not as close to production. Yes, the spokes are made of textile (ultra-high-molecular-weight polyethylene, or UHMWPE, think Dyneema). And yes, they are for XC mountain biking. I have to admit my initial scepticism coming from the rugged and notoriously wet weather of Scotland’s Tweed Valley. However, I have been assured that the PE is tensioned so high that all voids between the fibers are closed such that dirt, dust, grime, mud, sand, gravel, or whatever else you might throw at them, can’t get in amongst them.

Tune even tells us they will stay white, as the closed voids will keep dirt & mud out. Curiously, the fiber spokes made by Berd fit within standard hubs & rims. The get a looped end at the hub with a short piece of fiber inserted as a plug, and they capture a short section of steel spoke with threads at the nipple, held in place finger trap style.

The wheelset is made with Tune’s lightest carbon mountain bike rims and therefore is set to be one of the lightest for MTB on the market, weighing in at just 999g. The use of the textile-based spokes is marginally less stiff, providing greater vibration damping and said to improve ride quality. Tune’s innovation efforts were rewarded, winning the Eurobike Award for componentry.

Lastly from the prototypes, the Ahead Cap AL Skyline or more simply dubbed the GumGum’s headest cap moves the fastest from prototype to production. Machined down to just 4.9g including its bolt, this is the cheapest way to add a little fancy Tune customization to your bike, in all of their anodized colors. For just about $20€ it is as light as anything out of carbon but stronger.

New kit, already on the market now

Two new wheelsets were launched at Eurobike, for both road and gravel riding. Their deepest aero rims drop a few spokes, hubs get updated with more rotor & freehub options, and the elusive carbon Schwarzes Stück retruns as the Beste!

The first wheels are the carbon Schwarz Brenner 45 wheelset with an inner width of 18mm. While the majority of carbon rims are handmade, automated production has been rolled out for these new rims. This will undoubtedly reduce variation among the rims and reduce manufacturing defects. The rims and hubs are made in Germany while the nipples and spokes are made in Belgium. The wheelset weighs 1448g and comes with Kong centre lock hubs available in 6 anodised colors.

A second option comes in the form of the aluminium TSR35 rim-braking road wheelset. With an inner width of 19.9mm these rims will host tyre widths of 25-33mm. The black brake track is twice-anodised to ensure the rim stays black for as long as possible.

Also on show at Eurobike were the new lightweight centre lock hubs from Tune, evolved from their previous 6-bolt predecessors. We saw them last year as a tease, with super limited availability.

1 lockring bolt instead of 6, and a smaller alloy interface means these hubs are considerably lighter. And now centerlock is available in all of the light King, Kong, Prince & Princess hub variants.

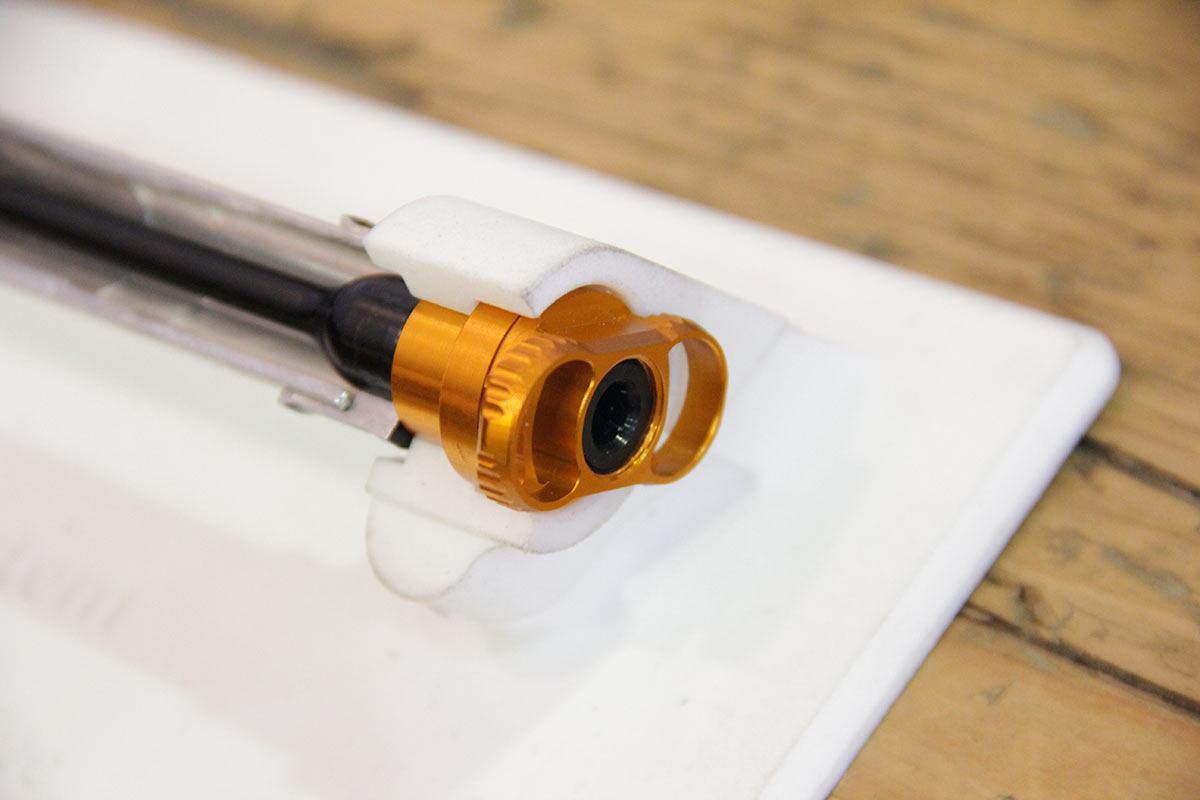

A sneaky new introduction was also this gold (in the future orange ano) hubshell. Hidden inside is Tune’s new XD high torque freehub body.

While it adds only about 10g, it is said to more than double the strength of the freehub body to withstand the added force from e-MTBs, heavier riders, and now the much higher torque being put on drivetrains by the giant 50, 51 & 52 tooth cogs of new 12-speed cassettes.

Liechtes, Schwarzes into Beste Stucks

Another update to something we’ve seen before… Tune has now fully launched their alloy seatpost with its newly refined two bolt head clamp. The 27.2 mm aluminum Liechtes Stuck seat post is not only aesthetically pleasing with the CNC machined bridge-like pattern – this also makes the post ultralight (155 g) ensuring strength is provided only where it is needed.

Now the aluminium light stick also comes in a shorter 340mm version to suit road bikes too.

Even bigger news is the return of a carbon variant. It was called the Schwarzes Stück back when Tune fought to make it as strong as the alloy version. Now they sorted it all out and the carbon post is back and better than before. So now it’s renamed the Beste Stück, with weights from just 122g, and 27.2 & 31.6mm versions and 350 or 400mm lengths.

Finally, (but still not quite available in the US) an updated production version of the Tune Linientreu laser derailleur alignment tool was unveiled. We saw it as a prototype last year, but the weightier new version promises to be even easier to use.