German-made Pi Rope showed us yet another example of superlight XC wheels built up with textile fiber spokes, and gave us the lowdown of why they actually outperform traditional steel spokes.

We recently saw Berd polyethylene spokes on Tune’s prototype wheelset slip under the 1kg mark, but those aren’t the only fiber spokes to be found on a mountain bike wheel these days. In fact, these polyester fiber spokes made by Pi Rope are actually already available. And Pi Rope can build them up into a XC wheelset as light as 1065g.

Pi Rope ultralight textile spoke mountain bike wheels

Quickly looking at the difference from these Pi Rope fiber spokes to those Berd ones found on the Tune wheels. Pi Rope’s textile fiber spokes are made of braided Vectran polyester fiber (vs. Berd’s Dyneema polyethylene).

The spokes are generally a bit thicker in diameter and utilize a nipple attachment methodology designed for the hollow braided structure that necessitates hubs & rims specific to this system. Pi Rope developed their own spoke end system that they say creates a better mechanical connection between spoke & nipple than the competition without extra weight or stress on the braided spoke.

Tech Details

They were a bit tight-lipped on exactly how the connection is made, but confirmed that it is a two-piece joint with one part inserted into the end of the hollow spoke, which then compresses into the nipple with its external male threads. In the end the spoke is held in the nipple both mechanically and with an adhesive.

To make that work Pi Rope has a development partnership with German wheel maker Newmen who supplies quality rims and hubs designed to accommodate the unique thread in nipples. For now Pi Rope is only having Newmen make Boost-spaced, 6-bolt hubs, but offers both alloy & carbon rims with the appropriate drilling. That is mostly to keep things simple as they establish their production capabilities relative to demand.

To eliminate any twisting (or wind-up) of the spokes, the wheels are built by initially threading the flexible textile spoke into the hub shell. Then the wheel builder inserts the nipple into the rim, and holds it fixed in place while they tighten a nut onto the end of the nipple through the rim. The result is no spoke twist, but it also limits the ease of adjusting the wheel with a tire mounted. In theory, it does retain some adjustability while turning both hub & rim nipples at once, but real adjustment should be done from inside of the rim well.

Why Pi Rope polyester textile spokes are better than steel spokes?

Pi Rope’s founder Ingo Berbig explained to us the benefits of their Vectran spokes over a traditional stainless steel spoke, essentially coming down to the much higher breaking force (or ultimate strength) of the polyester fiber spoke vs. steel. Essentially the Vectran spokes can withstand up to 6-8kN vs. 2.5-3kN for steel. With that in mind Pi Rope can lace and tension a textile spoked wheel with stiffness in mind, leaving plenty of extra spoke strength in reserve.

How that benefits a wheel build, is that the extreme of forces a spoke is subjected to get close enough to the limits of steel that the steel spoke will deform plasticly under a large impact which stretches the steel spoke to the point that it doesn’t bounce back. Now with the textile fiber spoke, that extreme impact force still happens entirely within the elastic range of spoke elongation, so even under a big impact the textile spoke will rebound to its original length. That means less need for wheel truing, especially when built up with a carbon rim that can move more elastically as well.

Durability is of course an important factor in spoke design, since you can’t just walk into any bike shop in the world and pick up a spare Pi Rope spoke. First off these Vectran spokes are already cut & abrasion resistant, remember this is the same material that gives tires like the Conti GP 4000 its puncture resistance. Plus, like the Berd polyethylene spokes, their own tension keeps them from collecting much in the way of contamination. Then to make the naturally golden fibers more durable, Pi Rope applies a milky white treatment to the completed spoke that reduces its tendency to abrade or fray and also protects against UV degradation. Additionally dying the spokes is possible, with the Pi Rope team already have made some in black, red & blue.

Pricing & Availability

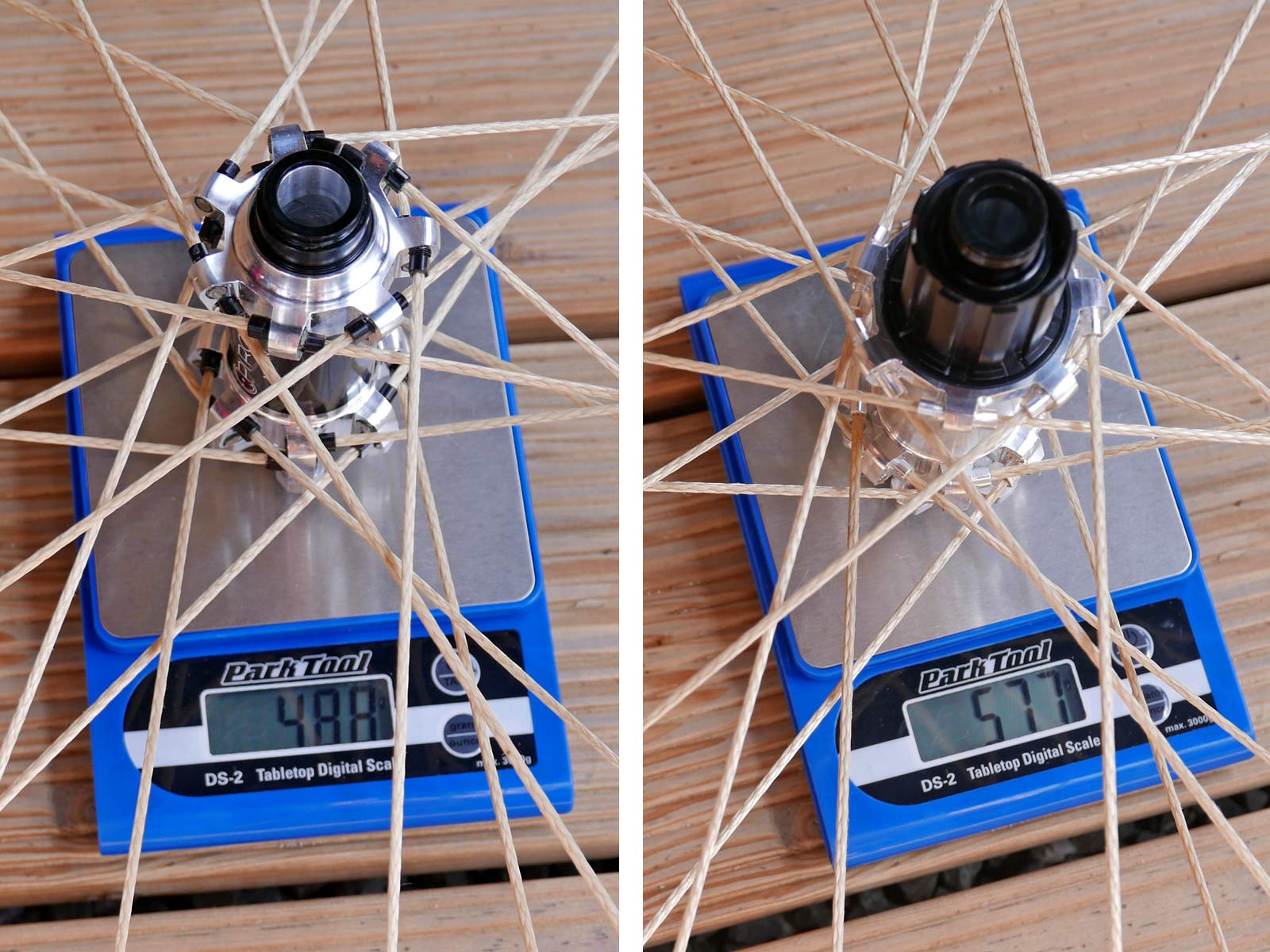

Pi Rope builds up three different cross-country and trail mountain bike wheelsets with their spoke system. The top of the line is the RL Squirrel X.22 29er wheels that tipped our scale at just 1065g (488g F, 577g R). The Squirrel wheels with their carbon rim sell for 1950€.

Additionally Pi Rope also has two alloy wheelsets that sell for around 1050-1200€ with 30mm (1445-1513g) or 25mm (1193-1236g) inner rim widths. Both of those wheelsets are built in both 27.5 or 29″ variants and geared for everything from cross-country racing up to all-mountain riding.

As for actual availability, Pi Rope is building the wheels now based on their patent application from 2016. As they are finalizing production setup it may take a little while to get a set of wheels, but you should be able to order them by contacting Pi Rope directly, with expected summer into autumn delivery based on availability.