Welcome to Tire Tech, Bikerumor’s mostly-weekly series on bicycle tires. Like our Suspension Tech and AASQ series, we take your questions about tires, whether it’s road, cyclocross, fat, plus, gravel, or mountain bike, and get answers from the brands and people behind them.

Whether you’re chasing your pals at a local weekend race or vying for a top spot at a World Cup event, tire choice plays a critical role in the performance equation. For this installment in our Tire Tech series, we dive into the science of cross country tires.

If you caught our interview with Tom Ritchey, you know he was the first to create tires purpose-built for high performance mountain biking. Some of his most advanced offerings were cross country tires and released long before that category officially existed. His pioneering principles are still a driving force in modern tire design, particularly on the XC front.

Objectives & Tech

As we have heard time and again, tire development is all about compromise. You can’t have the ultimate in traction without eroding rolling speed. Durability will always come at the expense of added weight. Tire designers must choose which attributes they feel are most important to achieve their desired objectives.

On the race course, XC tires must roll fast and hook up for short punchy climbs and quick accelerations. A lot of time is lost in turns, so a tire has to bite well enough to brake late and carve hard to help maintain speed. The best way to go from first to last is with a flat, so puncture and cut resistance is important. It’s a lot to ask of a tire with strict weight limitations.

Borrowing from road bikes

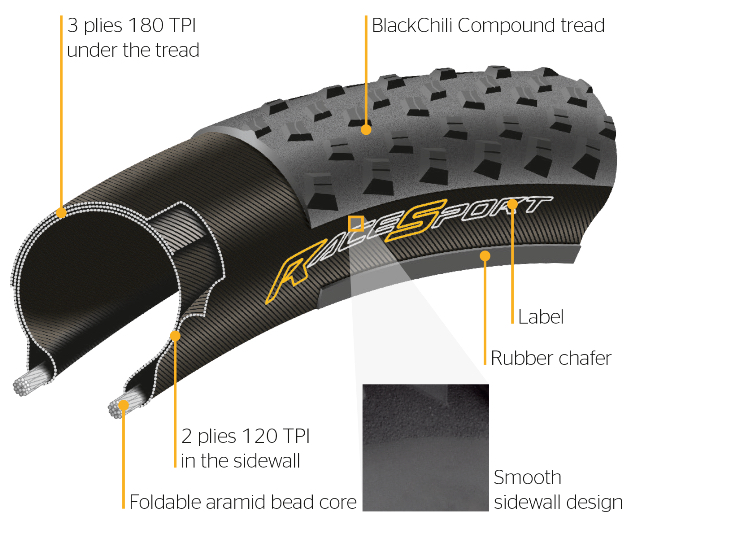

Early on, people like Ritchey understood the importance of the casing. He was the first to put road bike technology in a mountain bike tire. He understood how a supple and light carcass translated to speed. Brett Hahn of Continental echoed that sentiment and mentioned how their advances in road bike tires transfer to the dirt. Continental’s RaceSport casings start with 120tpi fabric overlapped at the tread cap for a light 3-ply construction. The sidewalls remain light and supple while the contact patch gains an extra layer of material for protection.

According to Tim Krueger of Terrene Tires, it’s not enough to start with a good casing. If you slather it with too much rubber all of the benefits of a high-quality casing are lost. Equally important are the additional layers added between the casing and tread features. Primarily used to improve puncture resistance, these high-tech layers offer support to the tread pattern and help reinforce the overall structure of the tire.

Knob shape, patterns, and pitch

With the casing sorted, the next step is establishing the objectives of the tread pattern. As we learned from Vittoria’s Ken Avery, tire design is about balancing the application with the conditions. An XC tire made for dry hardpack won’t work well in wet and sloppy terrain. This is why they offer a lot of different tread patterns aimed at the same application—racing.

When Ritchey set out to build his first fast-rolling tire, he created a knob pattern concept still in use today. By linking the knobs at the center of the tire he reduced the rolling resistance caused by the sawtooth effect as the tires roll over the ground. Other patterns like the uber-sleek Continental Speed King virtually eliminate central knobs altogether. The SpeedKing uses, “propulsion-oriented profile geometry,” or what look like fish scales to reduce rolling resistance. Obviously this won’t work for anything other than dry, hardpack courses, but it’s nice to have a tire optimized for such things.

Knob shaping & spacing

As we discussed in our Tire Tech article about knob types, the size, shape, and spacing of the tire lugs has a tremendous impact on rolling speed. The most important knob element for a fast tire is the use of ramps. Ramps help transition the weight of the load onto a lug with reduced resistance. This is why you will often find ramped knobs along the center of an XC tire but not along the edges where rolling resistance takes a back seat to cornering traction.

Another aspect easily overlooked is the “pitch” of the tread pattern. This is the term used to describe the spacing between the knob arrangements within the contact patch. A representation of how many times that arrangement is repeated within the contact patch, the pitch also determines rolling efficiency. Too tightly spaced and it may roll faster, but weight goes up. Too many voids in the pitch and traction and smoothness are compromised.

Rubber compounds and additives

Within the evolution of knob shapes and tire patterns, the final ingredient comes down to what’s mixed in with the rubber. According to Ken Avery, the most significant advancement in mountain bike tires is Graphene. The hot new wonder-material used in everything from running shoes to fighter jets, Graphene allows tire engineers to craft tread lugs that can endure the rigors of riding without premature wear and still have good grip.

Graphene is not the only way to achieve the ideal XC rubber compound. Continental’s 4C compound blends are the result of decades of science, all funded by their $42 billion automotive division. According to Brett Hahn, they can blend unique rubber compounds with the rebound qualities they need to improve rolling speed while not impeding durability or traction. It’s easy to overlook the importance of a dynamic knob. Mountain bike knobs are not static cleats. They are designed to move and bend as the tire rolls. How they do so imparts specific qualities to speed and traction.

How it all comes together

If it’s done properly, a good XC tire will have a light and supple casing, thin protective flat-prevention layers, a mild amount of rubber, and tread features designed to roll with as much speed and efficiency as possible. The rubber compound will provide optimal rebound with overall weight kept to a minimum. Hopefully the end product won’t give up too much durability so you don’t have to buy a new set of wheel skins every month.

Not all XC tires are built to the same end goal. Your best bet is to shop carefully and closely evaluate the various components within a given tire based on your local terrain. Not everyone needs extra cut and puncture protection, and those things add a lot of rotational mass. Some trails all but require it to finish a lap. If you’re chasing a podium spot, the last thing you want to do is make the wrong choice.

Pumped on this? Got a tire-related question you want answered? Email us. Want your brand or product featured? We can do that, too.