Four years ago, while interviewing Dave Weagle we got a hint at what was to come. There were no definitive plans at the time, but Weagle mentioned that he had an all new suspension platform named Orion that would be perfectly matched to a 1x drivetrain – only there were no plans for it to be used on a bicycle. Originally developed for motorcycle use (hence the 1x specific nature, just with a sprocket instead of chainring), Weagle was keeping his options open in terms of licensing the design – to motorcycle or mountain bike companies.

About the same time, Tim Krueger was just starting to form his rider-owned empire. His long term plan would be to have a high performance mountain bike company with carbon frames, but the lengthy development time of carbon meant that he could pursue other things in the mean time. While Esker Cycles was being created in the background, Tim went on to found Advocate Cycles as a way to learn more about the ins and outs of owning a bike company while simultaneously giving back to the community. Then there was Terrene Tires – another way to learn more about the industry while creating a “house brand” tire so to speak that was purpose built to fit the needs of first Advocate, and now Esker.

Fast forward four years, and we’re seeing the first results of Tim’s massive investment in carbon molds with his first carbon bike, the Elkat. Not only is this Esker’s first model, but it’s the first bicycle in the world to use the Orion suspension system that Dave Weagle designed. As it has been in the past, the development of the Elkat around the Orion system was a very hands-on affair with Esker’s engineer Anders Broste working directly with Weagle to ensure that the suspension system lived up to its potential.

Throw in some killer design work from Jason Ness, and you have a mountain bike that rides as good as it looks – if not better. Combined, the team of industry veterans behind Esker have over 100 years of collective experience according to Krueger – and everyone rides. That’s a big part of the Esker brand philosophy. As a rider owned company, they want to design products that the end consumer can “ride any trail, anywhere, and know that they will be fully capable,” and know that it will stand up to the abuse.

The Orion Project

Originally, the Orion project was slated for motorcycle use and because of that, Weagle was holding off on licensing it to mountain bike companies. However, in an apparent win for the world of mountain bikes, the motorcycle project never panned out and in December 2014, Tim and Dave started discussing an Orion equipped mountain bike.

According to Orion’s original patent filing in 2010, the system’s biggest advantage is the ability to “maintain a stable squat response magnitude under powered vehicle acceleration.” It goes on to discuss how many suspension systems allow this squat magnitude to vary widely based on where the wheel is in the travel which causes an inefficient design that results in a loss of energy. The Orion system maintains a stable squat response throughout the full range of travel to make for a very efficient pedaling bike that also increases the ability of the suspension to absorb bumps while also improving traction.

To do it, the Orion system has a one piece swingarm assembly that rotates around the bottom bracket with two short links below, and a clevis shock yoke up top. The bottom link rotates around the bottom bracket, but the bottom bracket itself does not move. The massive size of the main lower link should help with frame stiffness along with the blend of high modulus carbon fiber with Smooth AF carbon molding. All suspension pivots utilize sealed cartridge bearings with dual row bearings used on the swingarm.

The frame shown in all of our photos is the last prototype version so a few things will change – like the cable mount on top of the upper link. That will be gone for production. Not shown is a custom e*thirteen taco bash guard that will make use of the splined interface on the 73mm threaded BB shell and the 2/3rds ISCG 05 mount.

As mentioned, the Orion suspension system is specifically designed around a 1x drivetrain – so no front derailleurs here. As Tim points out, when the bike was first being developed four years ago, building a bike that was 1x only was still considered a risk. But as we’ve seen with 1x everything for mountain bikes, it’s a risk that seems to have paid off. Not to mention the Orion system seems to finally make good on those promises of better suspension designs thanks to the chain being in a single chainring position when 1x systems were first appearing as early as the days of Truvativ Hammerschmidt.

Key to the design of the suspension is that the kinematics of the frame are responsible for the performance of the system, rather than relying on shock technology. That means the shock runs lower compression and rebound damping for extremely active suspension when you need it and efficient pedaling when you don’t. You’ll still find a custom tuned Fox Float DPS rear shock with metric sizing, but it’s not far from your average Fox Float – just with a custom level of damping.

150mm of travel, 27.5″ wheels

While the suspension is sure to get a lot of attention, there’s also the addition of an entirely new bike company and their first carbon frame. Named after the geology term referencing a serpentine ridge formed by streams in glacial ice, Esker joins Terrene Tires as another brand under the Krueger Outdoor Inc. roof.

The Elkat is a 150mm travel all-mountain bike that is built around 27.5″ wheels and has clearance for up to 2.6″ tires. Bikes will ship either with 150mm or 160mm forks. The cable routing is a mix of internal shift and external brake, though we’re told a few changes have been made to the cable ports for production.

The frame has all of the features you’d expect like Boost 148mm rear spacing, internal dropper compatibility, a 44/56mm ID internal headset, and frame protection for the chainstay, seat stay, and two spots on the downtube (lower section, and upper section for tailgate pads). We’re told that rather than molded plastic, Esker is opting for custom 3M helicopter tape application since it ends up lighter than the molded pieces and offers a surprising amount of protection. That, and we’re sure it’s a lot less expensive for a new brand to produce than custom molded plastic/rubber pieces. You’ll also find a bottle cage mount inside the front triangle with plenty of room for a larger bottle even on our test bike which was a medium.

Rather than try to hide it, the Kruegers have always been proponents of the idea of “Handmade in Taiwan.” These frames are indeed made by hand in Taiwan by people that take a lot of pride in their work. My first carbon frame factory tour in Taiwan was actually arranged by Tim years ago, and it wasn’t until writing this post that I realized he was actually showing me the factory that would later make his bikes. And that factory was extremely impressive – clean, well organized, and home to some other big name brands.

Slack & Steep Geometry

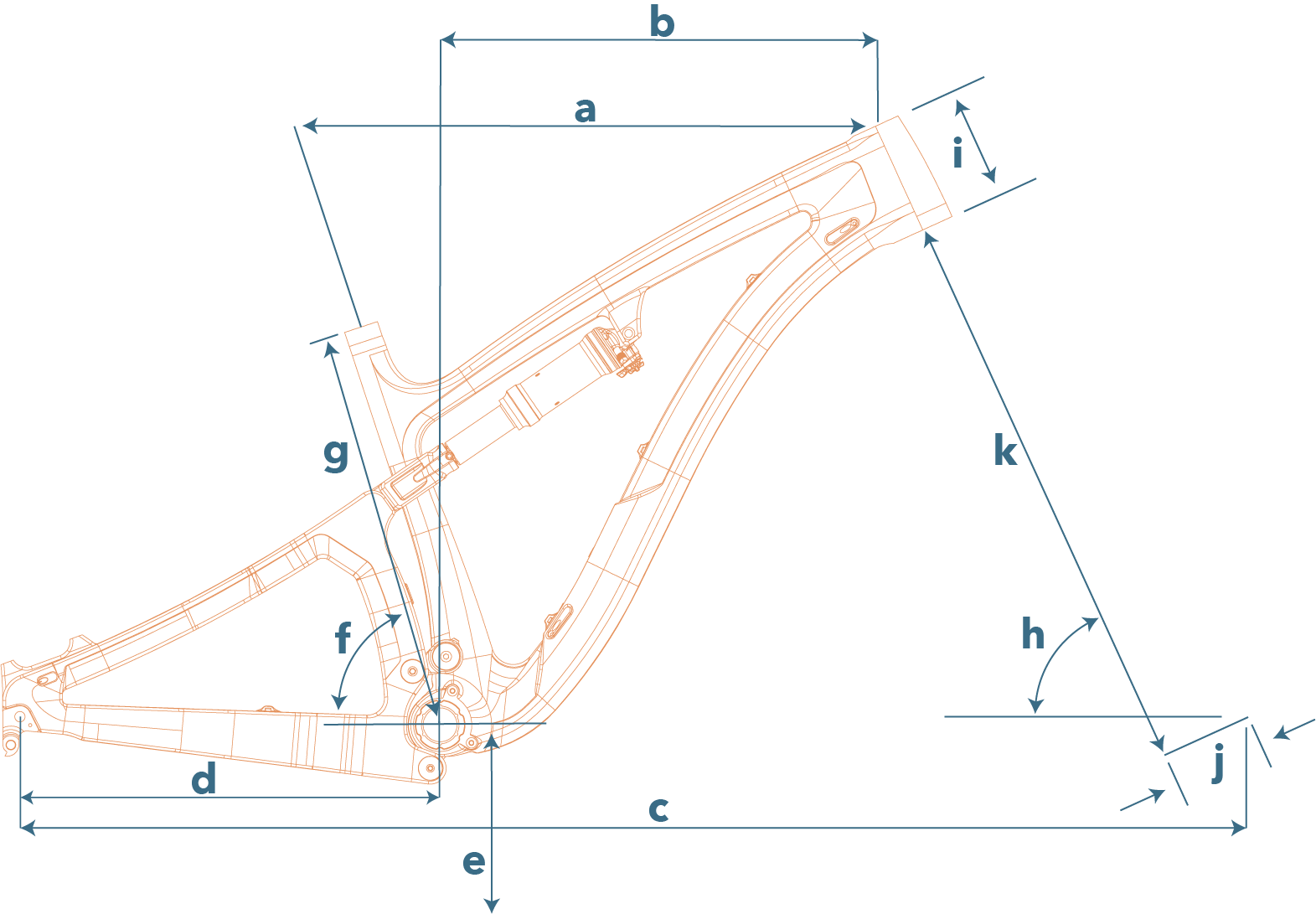

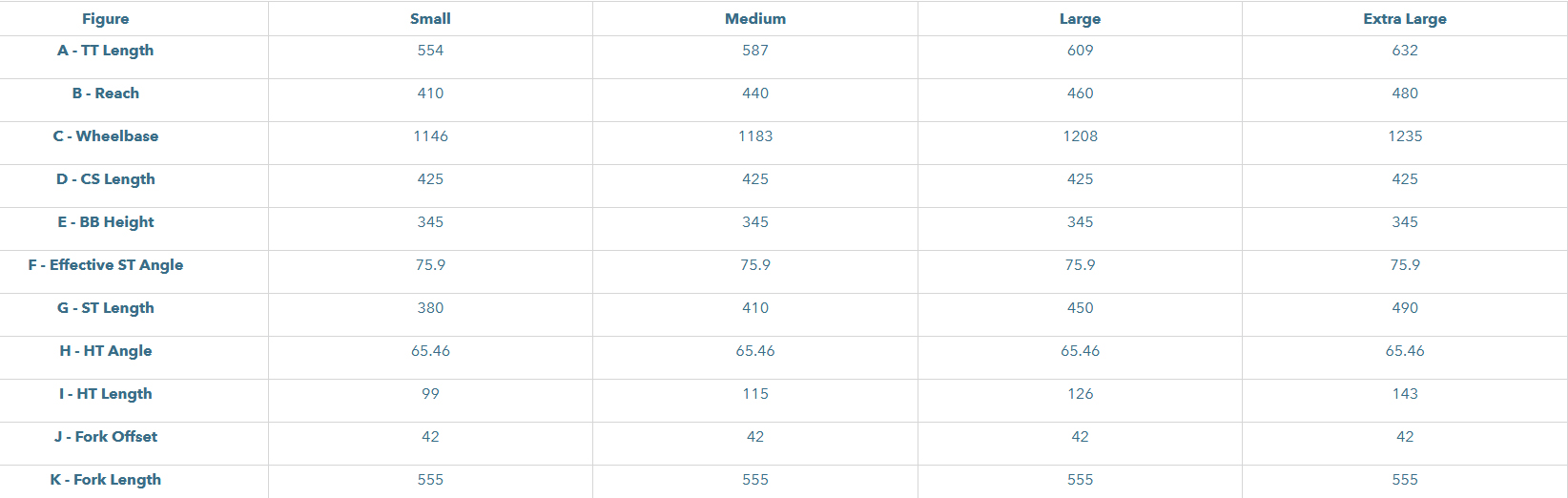

We’ve been seeing a steady evolution of mountain bike geometry and the Elkat continues that. If you’re not used to modern mountain bike design with steep seat tube angles and slack head tube angles, the Elkat will take a bit to get used to, but the idea is that it’s designed for dual purpose. When climbing, the frame’s steep effective seat tube angle of 75.9° puts you in a position that’s ideal for maintaining traction and using the muscle groups best suited for climbing.

But when the trail points down, the advent of the dropper post has allowed bikes like the Elkat to drop the saddle so that it’s out of the way, letting you get into an attack position for controlled descending. The Elkat is definitely not an ultra long reach monster like a Mondraker however, as the resulting saddle position of the bike actually makes it feel fairly short when seated and pedaling, but more on that in our first ride review.

Pricing / Availability / Builds

Starting with your choice of four frame colors, riders will have the ability to purchase frame kits for $3,000 which includes the seat collar, the Fox DPS rear shock, Wolf Tooth Components headset, spare derailleur hanger, and pivot service tools. Complete builds will start at $4,000, but the idea is that each bike will be hand assembled to order with the individual owner choosing all of the parts based on their needs and wants. Because of that, Esker will be primarily consumer direct, though we’re told there will be a limited group of national retailers that will offer the same kind of service – start with the frame and hand pick your build.

Your first chance to demo an Esker Elkat is this weekend at Outerbike Crested Butte. But if you don’t happen to be within driving distance of Colorado, Esker will have demo bikes at a number of consumer events for the remainder of the year with the goal of delivering production bikes by December. If you want to guarantee your own bike from the first batch, Esker will be offering pre-order reservations for $500 which includes immediate delivery of an Esker gear pack with a hat, t-shirt, and a custom High Above x Esker hip pack shown above. That $500 will of course then be applied to the price of the bike once delivered.

What about Advocate Cycles?

The Advocate Cycles brand has evolved into Esker, but that doesn’t mean favorites like the Hayduke are gone for good. We’re told that a new and improved version of the (now) Esker Hayduke is on its way, and we’ll see more bikes under the Esker brand in the future.