Has it ever occurred to you that your bike’s wheels do two different jobs? Well Crankbrothers says that is the case, so they’ve tuned the front and rear wheels of their new Synthesis carbon wheelsets to perform their separate duties as well as possible.

The theory, in short, is this: Your front wheel’s job is to find traction, so this wheel has more compliance than the rear and is slightly wider. The rear is stiffer and stronger as it will bear the brunt of most hits and lateral cornering forces.

This article covers the development and tech specs on the new enduro, DH and XC/trail Synthesis wheelsets, but I’ve actually been riding the E 11 wheels since late August; be sure to check out my review to see how they handled on the trails.

To develop the Synthesis wheelset, Crankbrothers brought together two wheel builders with opposite approaches. On one side is Jason Schiers, founder of ENVE, whose wheels were known among MTBers to be very stiff. On the other hand, Mello Bouwmeester was building compliant, single-wall carbon rims under his own brand in Australia. With expertise on both ends of the scale Crankbrothers started building test wheels to determine what level of stiffness, and in what combination, was best for mountain bikes.

The company put test riders on unmarked prototype wheelsets that offered different stiffness levels and combinations front to back, and eventually the test group’s preferences narrowed down to one set – the pair with a compliant front wheel and a stiff rear ticked the most boxes, and the Synthesis formula was found.

The concept certainly seems logical – the softer, compliant front wheel offers a slight degree of flex to keep you better connected to the trail as you thrash through rough terrain. The rim is also slightly wider than the rear, to spread the front tread wide and round. Pairing different rim widths isn’t a new idea, but it simply furthers the concept of running wider front tires with narrower rears, which many riders have done for years.

Since it takes the hard hits and deals with torque and cornering forces, the rear wheel was kept stiff and strong. The rear rim is a bit narrower than the front so the tire keeps a sharper profile and solidly bites into corners.

One obvious way Crankbrothers kept the front wheel softer was using fewer spokes than the rear – the Synthesis wheelsets all come with 28 spokes up front and 32 out back. What the eye won’t see is that the front spokes are under less tension than the rears, and while the front rim is wider it actually weighs less than the rear rim. Out back, higher spoke tension, heavier gauge spokes and a stronger rim keep things tough enough for off-road abuse.

If you’re skeptical about carbon rims because you’ve seen them blown to pieces, you might want to hear this; while building the Synthesis wheels, Schiers honed in on how to make these rims fail without doing so catastrophically. The Synthesis rims are designed to crack like an alloy rim would, and not explode upon impact. And since they’re carbon, you can’t flat spot them like aluminum rims.

Crankbrothers wasn’t shooting to create the lightest wheelset available, but favoured durability and ride-tuning instead. There is no rider weight limit, and the Synthesis wheelsets all carry a lifetime warranty to the original buyer.

There are three different Synthesis wheelsets with two specs for the trail/enduro models and one premium-level DH set. The lesser models offer the same ride qualities as the higher-end options, but the pricier wheels are lighter. The rims follow the same design across the board but the rim width, hubs and spokes vary between models.

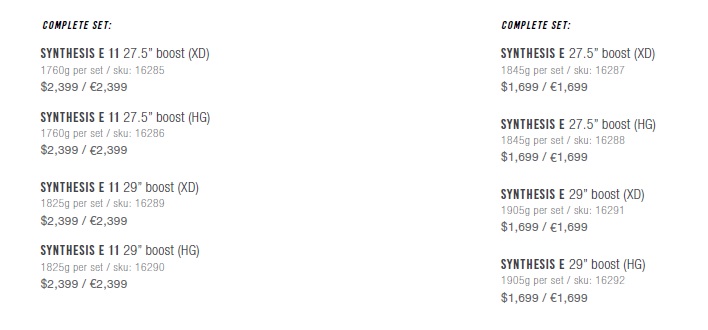

Synthesis E and E 11:

As you might guess, the E series wheels are intended for enduro riders. The front rim has an inner width of 31.5mm, while the rear is 29.5mm. The E model runs a three-pawl Synthesis Standard hub with 17° engagement, and they’re laced with Sapim’s D-light front and Race rear spokes.

As you might guess, the E series wheels are intended for enduro riders. The front rim has an inner width of 31.5mm, while the rear is 29.5mm. The E model runs a three-pawl Synthesis Standard hub with 17° engagement, and they’re laced with Sapim’s D-light front and Race rear spokes.

The premium E 11 wheels (pictured above) have a Project 321 built Synthesis 11 hub with 2.5° engagement, and bladed Sapim CX-Ray front and CX-Sprint rear spokes. The Synthesis 11 hub has six low-drag magnetic pawls (as they come stock) that make the hub run nearly silent. However, an optional ‘loud kit’ is available for those who like to hear their hub buzzing. The loud kit uses the same number of pawls and offers the same quick engagement, but the pawls are shaped differently to create more noise.

Both sets are available in 27.5” and 29” with Boost spacing for Shimano/Sram. See the below graphic for pricing and weights.

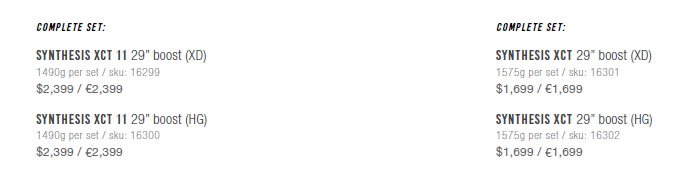

Synthesis XCT and XCT 11:

The XCT wheels are the lightest option for XC/Trail riders, and come in 29” only. This set’s front rim is 26.5mm wide, and the rear is 24.5mm. The basic XCT set uses the Synthesis Standard hub and Sapim D-Light spokes front and rear. The XCT 11 steps up to the Synthesis 11 hub and Sapim’s CX-Ray spokes. The XCT wheels come in Boost spacing only, and are Sram/Shimano compatible.

The XCT wheels are the lightest option for XC/Trail riders, and come in 29” only. This set’s front rim is 26.5mm wide, and the rear is 24.5mm. The basic XCT set uses the Synthesis Standard hub and Sapim D-Light spokes front and rear. The XCT 11 steps up to the Synthesis 11 hub and Sapim’s CX-Ray spokes. The XCT wheels come in Boost spacing only, and are Sram/Shimano compatible.

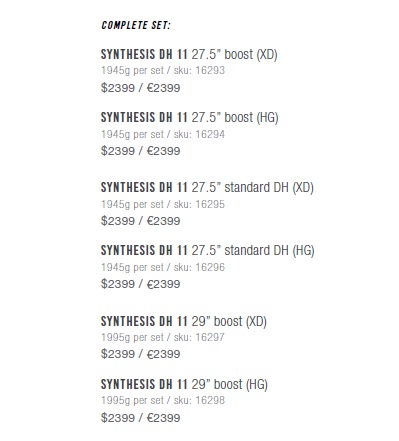

Synthesis DH 11:

The DH 11 wheels are intended for downhill riding. Since DH riders typically run 2.5” treads front and rear this is the only Synthesis wheelset where both rims are optimized to the same 31.5mm width. This set runs the Synthesis 11 hub, and Sapim’s CX-Ray front and CX-Sprint rear spokes. The DH 11’s are available in 27.5” Boost and Standard DH spacings (157x12mm rear/20×110 iso front – a separate axle kit is available for 150x12mm rear hubs too). 29” models come in Boost only, and all are Shimano or Sram compatible.

The DH 11 wheels are intended for downhill riding. Since DH riders typically run 2.5” treads front and rear this is the only Synthesis wheelset where both rims are optimized to the same 31.5mm width. This set runs the Synthesis 11 hub, and Sapim’s CX-Ray front and CX-Sprint rear spokes. The DH 11’s are available in 27.5” Boost and Standard DH spacings (157x12mm rear/20×110 iso front – a separate axle kit is available for 150x12mm rear hubs too). 29” models come in Boost only, and all are Shimano or Sram compatible.

The Synthesis enduro wheelsets are available online as of today (Oct. 1st), and in stores for November. The DH and XCT sets will be coming later this year. The E, DH and XCT rims are all also available separately for $699 USD per pair, with 27.5” and 29” options for the DH and enduro sets and 29” only for the XCT.

Eventually, ‘super boost’ 157mm rear hubs will become an option on the Synthesis wheels. For those interested in buying rims alone, Crankbrothers will provide wheel building specs to bike shops.