We’re just back from the 2018 edition of the Philly Bike Expo, and as usual, there were tons of impressive bikes and great people. But there were also a few surprising smaller items like bags, accessories, and tools. If you happen to be a bike nerd and/or a mechanic or former mechanic, one of the most interesting had to be the new Disc Brake Mount Facing Tool from VAR.

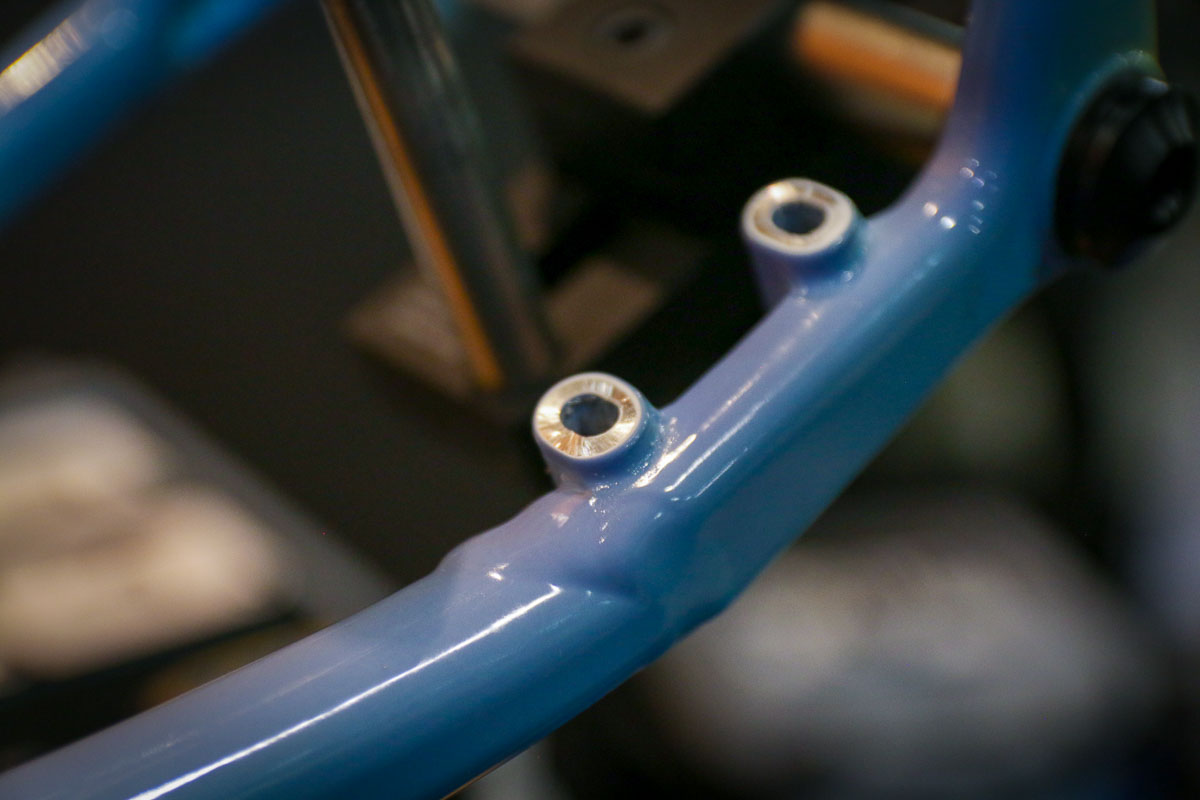

For those unfamiliar with disc brake mount facing tools, once a frame is welded or bonded and then painted, powder coated, or otherwise, even the best frames won’t have perfect brake mount alignment. Now, the better companies will face their mounts before the bike is sent out the door, but the majority of them end up shipping out with mounts that are “good enough.” Improperly faced mounts can cause brake calipers that can’t be properly adjusted leading to noisy braking or worse.

The best shops out there will catch these frames before they head out the door and face the mounts during the build. That usually involves an apparatus that positions a single cutter at each brake mount, one at a time, to remove paint and extra material to create a flat and properly aligned mounting surface.

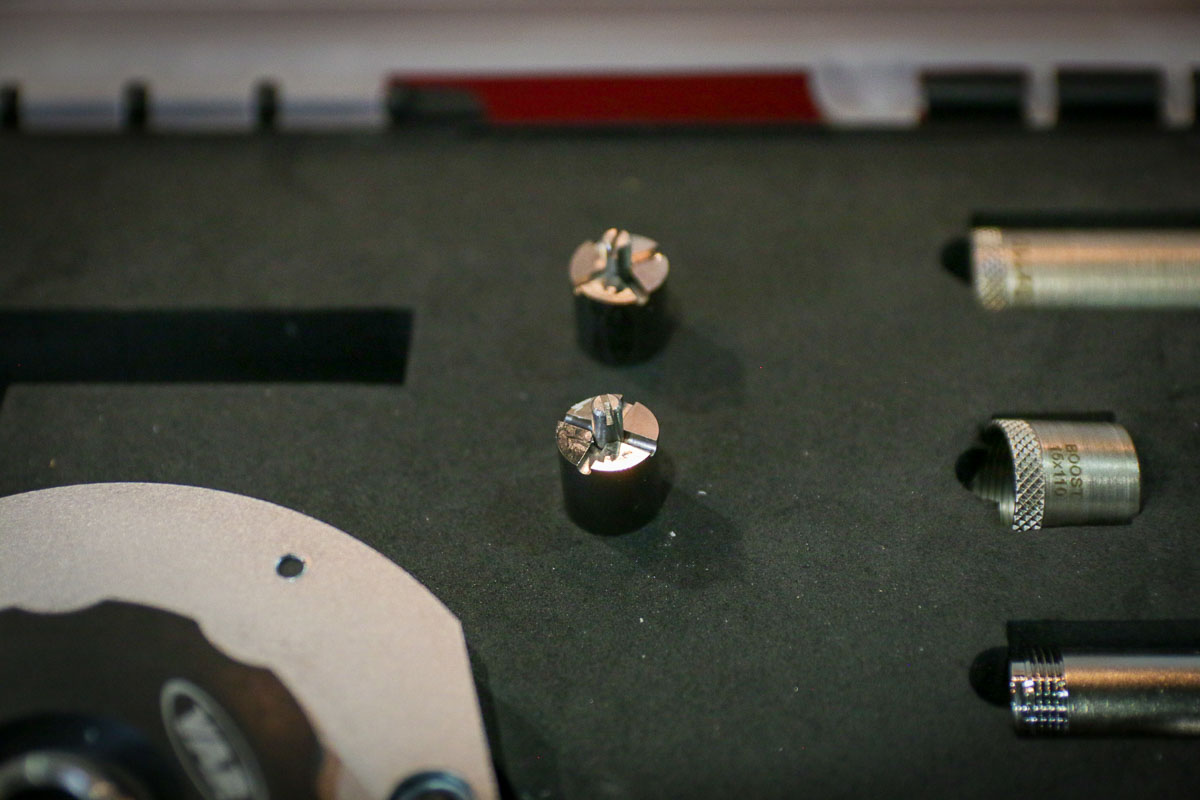

The addition of the flat mount brake brake standard adds another layer of complexity to the process, so VAR’s latest tool will work with the new standard. But they took it one step further and created a tool that not only works on flat mount, but also faces both mounting holes at the same time for perfect alignment.

The tool will also work with standard IS mounts and post mounts as well, plus it will work with quick release (9×100 and 10 x 135mm), and standard and Boost thru axles making it an all-in-one solution for shops. The kit included two sets of cutters, one for post mount and flat mount and one for IS mounts.

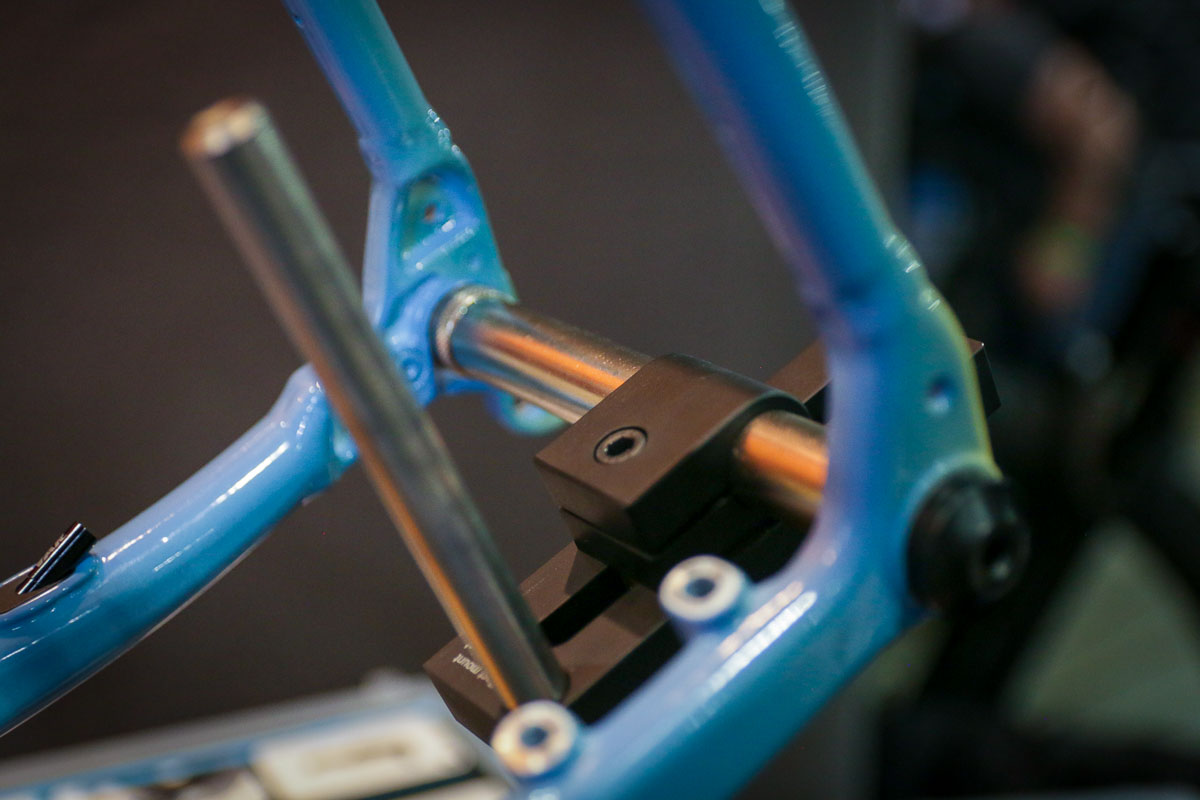

Once you mount the tool to the fork or rear axle, the cutter disc is placed on the mounting post. After adjusting the position to fit the frame or fork, you simply push down on the tool body and turn the dial with your other hand to turn both cutters at the same time.

As you might expect from a tool of this caliber, the price will put it out of reach for the average consumer (who probably shouldn’t need to do this enough to justify it anyways), but interested shops in the U.S. should reach out to Mel Pinto Imports who has limited stock.