Back in the day, if you were going to build a custom set of wheels, chances were pretty good you’d be surrounding them with Mavic’s alloy rims. Over the years, they’ve continued to offer those, updating them with their latest tech, machining tricks and designs, even if complete wheels have mostly take over. Now, though, they’re bringing their real latest and greatest to the custom wheel building market: Carbon fiber.

Four Mavic carbon rims will be offered, the Open Pro Carbon UST Disc, and the CXP Pro Carbon UST in both rim and disc brake versions. Quick specs are:

CXP Pro Carbon UST Disc

- 450g

- 19mm internal / 28mm external / 45mm deep

- 20/24/28/32 hole options

CXP Pro Carbon UST

- 425g

- 19mm internal / 25mm external / 25mm deep

- 20/24/28/32 hole options

Open Pro Carbon UST Disc

- 405g

- 21mm internal / 27mm external / 32mm deep

- 20/24/28/32 hole options

Open Pro Carbon UST

- 425g

- 19mm internal / 25mm external / 25mm deep

- 20/24/28/32 hole options

All are tubeless ready and ship with tape, valve stems and nipple washers. All three start shipping in April 2019, $499.99 each. Rim brake models get the laser-etched braking surface and they recommend their brake pads, but those aren’t included.

The point? To give riders options. Their high end wheels will still use their Zicral or stainless elliptical or bladed spokes, but they know that some people want to build with other things. And they know that using standard spokes (or letting people build with standard spokes) increases user friendliness in some situations. So, in addition to the rims…

…they’re also making standalone hubs. They’ll use traditional flanges for J-bend spokes, with rim brake versions available in 20h front/24h rear, and disc brake versions with 24/28/32 hole options.

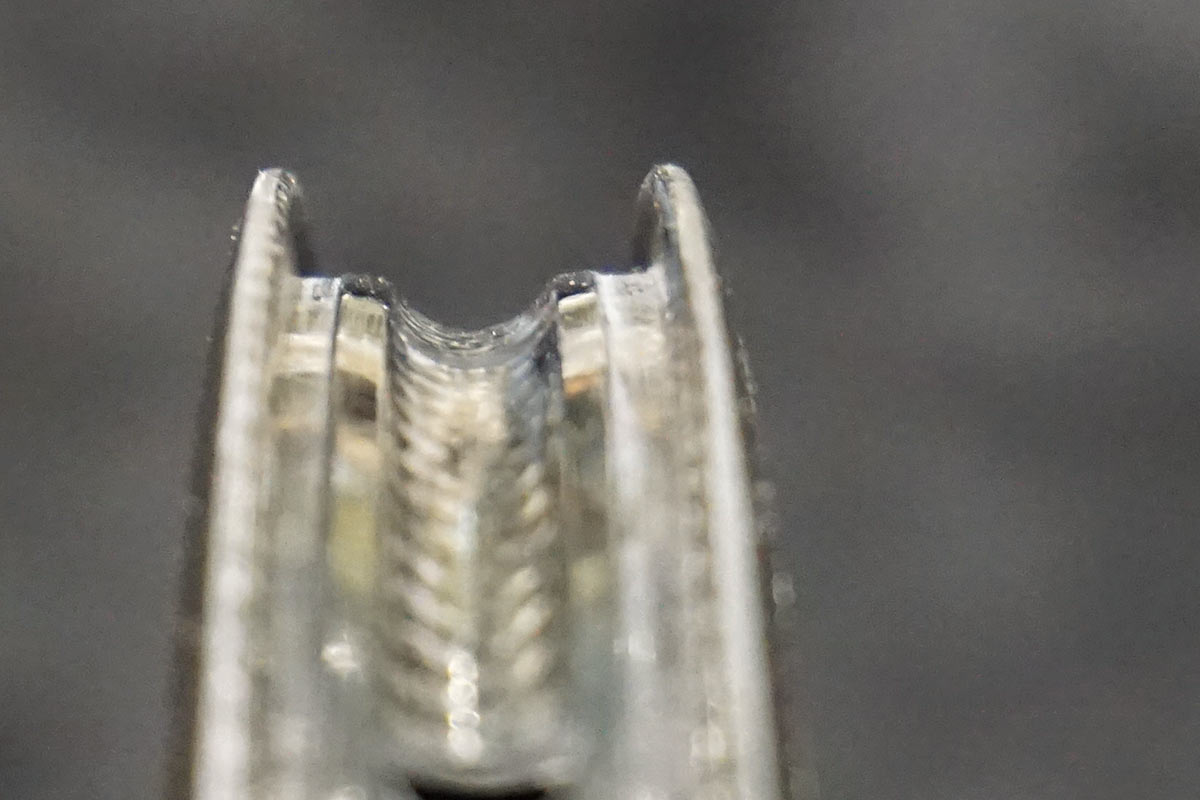

The rear will use their ID360 engagement mechanism (you can learn more about that in our recent AASQ installments with Mavic – Part 1 and Part 2), and both front and rear will use their QSM wave washer system to automatically maintain proper bearing preload.

Price and weights are TBD, these will come a little later this summer, but Mavic’s rep said they’ll be light…they’re aimed at the high end.

The Open Pro alloy rim is still available and looks sleeker then ever.

Prototype Carbon Mavic Gravel Wheels

These prototype carbon gravel wheels are coming this year, probably in summer, and they wouldn’t say anything about them just yet. But they’re out for all to see, and they look plenty wide.

They gave the 700×40 Yksion Elite Allroad XL tires a nice round profile. The bottom set is 650B with a WTB Resolute 42.

They’ll use Mavic’s proprietary direct-pull bladed spoke design with the QSM/ID360 hubs. More on these as they get closer to launch.