Ibis Cycles turned 38 at the beginning of April, and to celebrate they’re launching the 4th generation Ibis Ripley full suspension mountain bike. It’s a new bird, flying straight into the popular lightweight trail bike category with fully modern features and geometry. Beyond the updated angles and lower, longer, slacker (yet also steeper) design, there’s a new suspension layout that is both simpler and way, way lighter than before.

The original Ibis Ripley soft tail mountain bike.

The original Ibis Ripley soft tail mountain bike.So, what’s new, Ripley?

The original Ripley debuted in ‘99 as an alloy soft tail. The model was relaunched in 2011 as an XC marathon bike. Or, rather, it was announced in 2011 and finally made it to market in 2013. After which is was quickly pushed to do more, even being used in EWS. The Ripley v3 added a bit more travel and tire clearance, offering 120mm of travel and clearance for 2.6” tires. Both the 120mm travel and massive 29×2.6″ tire clearance carry over for this v4 Ripley, but that’s about it.

The big change is the switch from the original eccentric pivot system to a more traditional pivot system, and it’s all about that seat post drop. With more dropper posts getting longer and having more travel, they needed to make room for more seatpost insertion and lower the overall standover.

It still has a one-piece rear triangle, which manages to shorten the chainstays to just 432mm thanks to a forward-offset seat tube. That seat tube has a 76° angle, and reach stretches 45mm longer on all sizes. They say this combo puts you in a more centered position, which really keeps the weight over the pedals for better climbing traction. They also made the seat tube as short as possible to allow for the longest possible dropper posts…even size small frames can run a 125mm-150mm dropper and fit a full size bottle in the front triangle. All other sizes fit a 175mm dropper. Impressive.

Even more impressive is that the frame is one half pound lighter. They claim it’s just 5lb (size M, without shock), and that the top-level XTR build shown at the bottom of this post can is just 26lb with a 175mm dropper post.

Weight savings come largely from removing the eccentric pivot system, but also from using a combination of bearings and bushings. They spec’d a 2g bushing in high stress, low rotation positions, saving a lot of weight over the 25g steel bearings they replaced. They say these work better for the application, since the lower pivots only move 8° and 20° max, so the bike still comes with a lifetime warranty.

And, it’s just as stiff as the enduro-ready RipMo, though, so there’s no sacrifices in handling or performance, just less travel. This means you probably won’t see any mid-model linkage upgrade kits like the Gnar-Core.

BB height actually increased a 5mm, giving it more clearance. Cables run mostly internally, and the bike is not set up for wired electronic drivetrains, but obviously SRAM AXS will work. It has cable tunnels in the front and rear of the bike, but no accommodations for Fox Live Valve. They say “it pedals well enough uphill that they don’t need to add a pound and $2k to the bike.”

It has ISCG adapter now, too, but no front derailleur mount.

The Reply v4 gets a 66.5° head angle with 44mm offset fork, which they say makes it feel like a 65° HA, but with the ability to keep your weight over the front tire better. Those measurements are based on a 130mm fork, but they say you could sub in a lightweight 120mm fork to create a marathon race bike, or bump it to 140mm for a more aggressive all-mountain bike. Whatever travel you choose, they recommend sticking with a 44mm offset fork.

So, do all of these changes make for a more talented Mr. Ripley? Check out our first ride review and find out.

Ibis Ripley v4 specs, pricing & geometry

The Ibis Ripley 4 will come as a frameset for $2,999, with complete bikes ranging from $4,099 with SRAM NX up to $9,399 with the new Shimano XTR paired with Race Face Next SL cranks.

Click any image to enlarge.

Another big improvement? They’re actually available and shipping as of this launch post…a big upgrade from the years of teasing the Ripley v2 gave us. Frames come in Blue Steel or Matte Braaap and are backed with a 7 year warranty, and bushings have a lifetime replacement guarantee.

Where are they made?

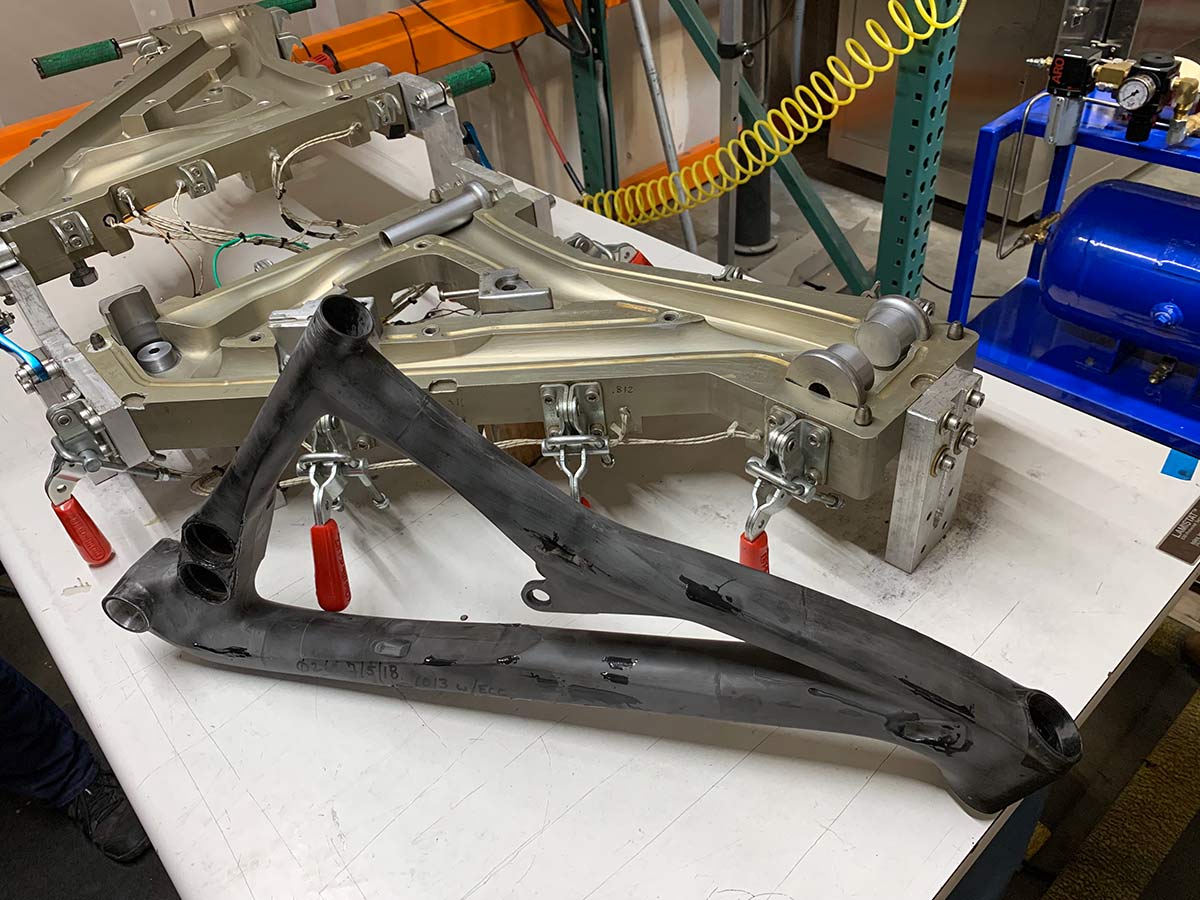

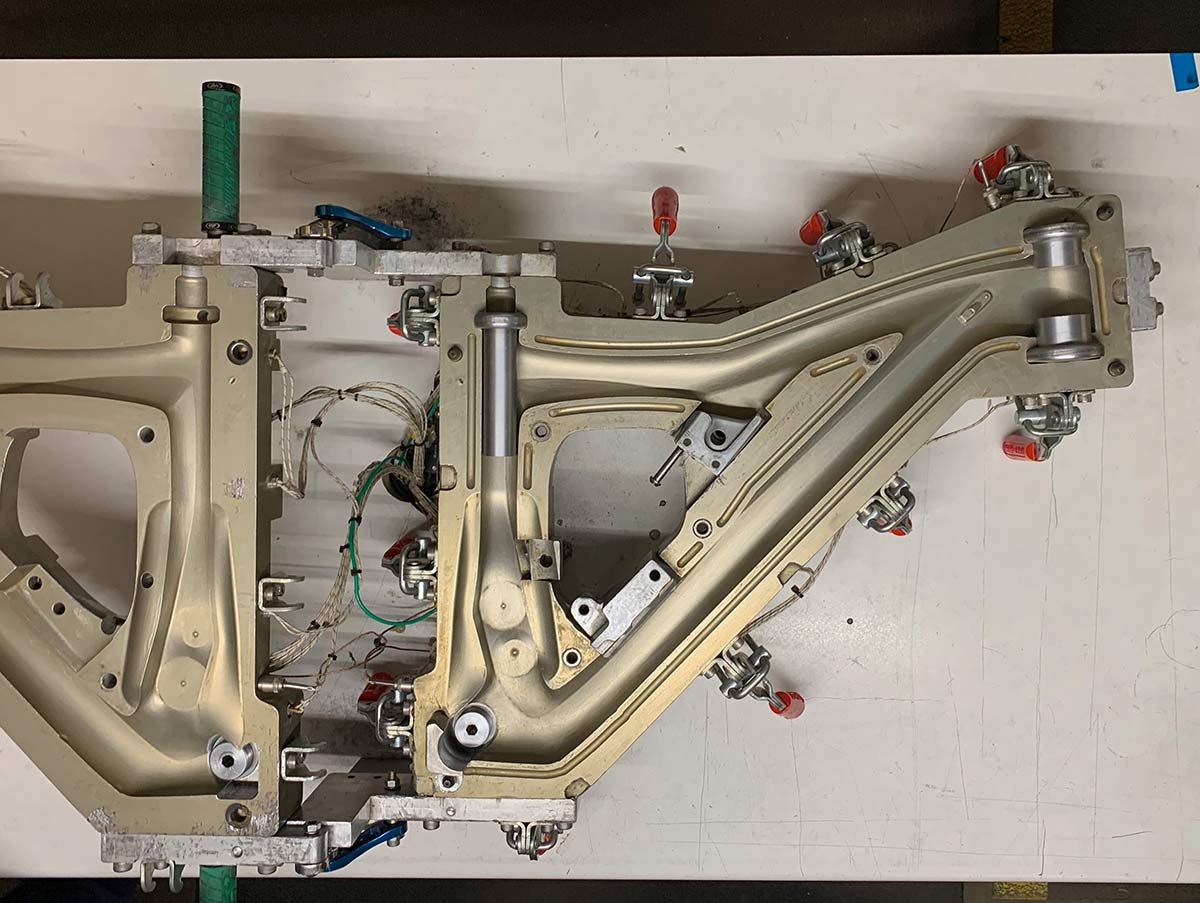

Do you recall the Carbon 831 Project they launched for the prior Ripley v3 bikes, where they were making the small frame sizes in house in Santa Cruz, CA? Well, that project is still something they’re developing, but not for the Ripley v4.

All sizes of this new bike are made in Asia, but they are still developing their US-made program to try to bring some of their carbon frame manufacturing back in house. Why? Or, rather, why not the v4? The point of the project was to prove that a really small full suspension 29er frame could be made at high volumes and with high quality. The challenge they originally ran into was that their factories looked at the layup required for the smaller frames and simply told them ‘no’. So they proved the concept in house, and took that knowledge to their manufacturing partners and showed them how to do it. It also taught them how to use fewer pieces of carbon to accomplish the same strength and stiffness, which reduced build time and complexity. So, the in-house project lets them test ideas and best practices, then apply them to the mass production factories they use in Asia.

And eventually, they say, bring some of that back to the U.S. The molds you see above are aluminum, and they use higher efficiency heat coils to get to temperature. This is not only way more energy efficient, but gives them much better control over the curing process, time and temperature, which is a huge technological improvement over the processes used by most factories…so they’re actually testing more than just layups, and they say this streamlined, efficient process could be the key to bringing some of this back to the U.S. and do so cost effectively.