Building on 25 years of Star Ratchet hub experience, the new DT Swiss Ratchet EXP drive system takes what was great about it, then improves on pretty much every hub metric. Lighter, stiffer, and more durable, it also has a drastically simplified layout with fewer parts. The new Ratchet EXP launches at the top-level in 180 hub, where it has already been ridden to a Cape Epic win this year, but DT expects that these improvements will make their way throughout their hub lineup…

DT Swiss Ratchet EXP introduces Star Ratchet 2.0

25 years ago DT Swiss patented their Star Ratchet freewheel engagement design with their original DT Hügi hubs, creating a generation of reliable, serviceable high performance hubs. Now that that patent has expired, we’ve been seeing more ratchet-style hubs vs. pawl hubs, so DT is upping the ante with promises of lighter weight, added stiffness, higher precision performance, longer durability, easier maintenance & simpler compatibility.

Ratchet EXP: It’s what is (or isn’t) on the inside that counts

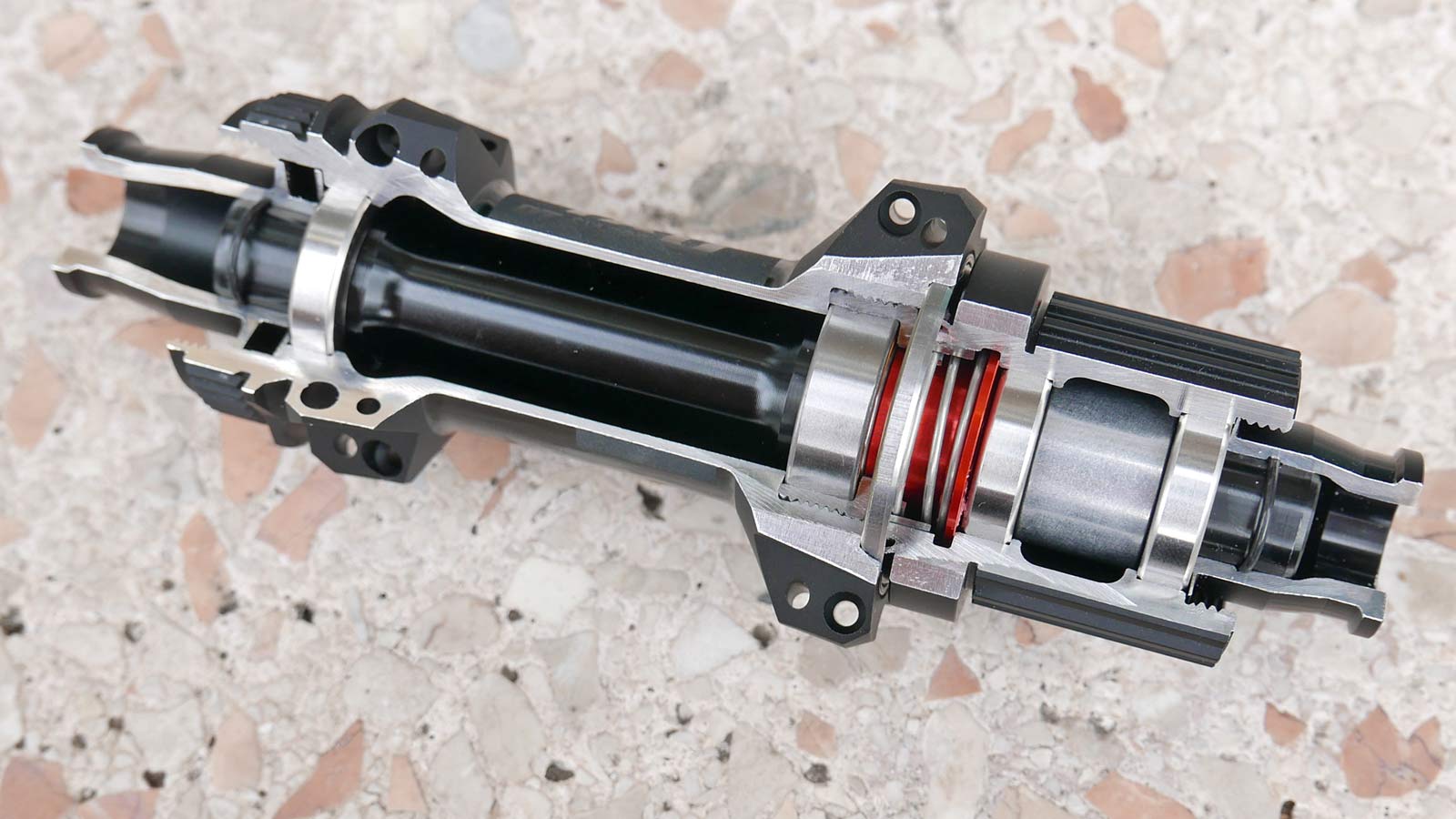

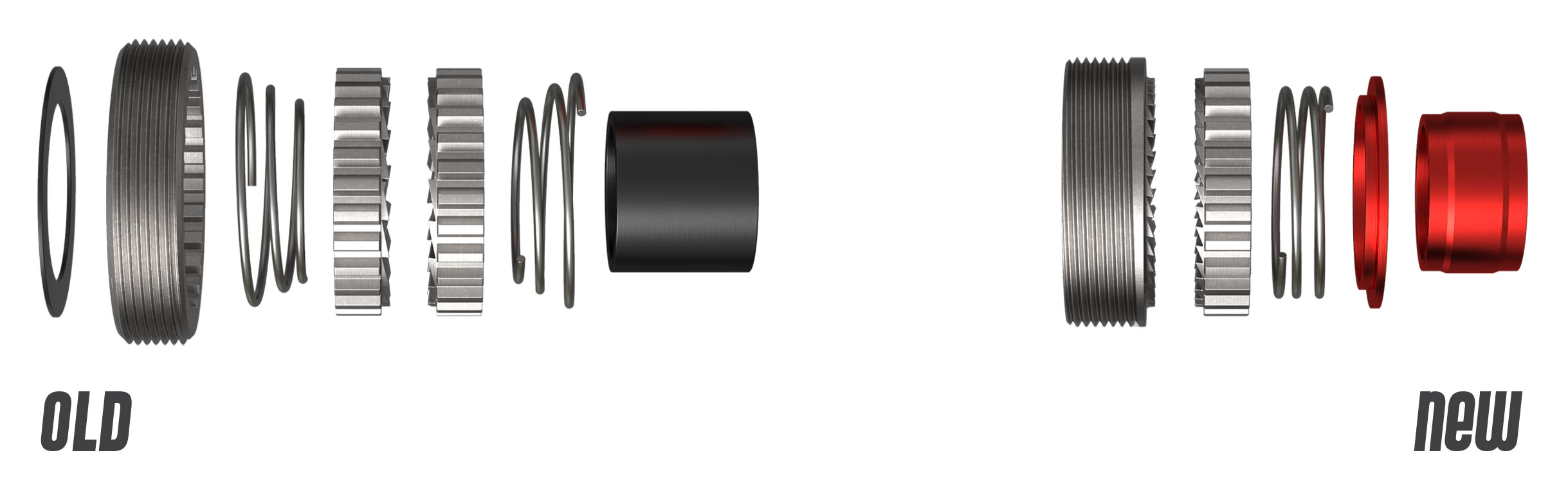

The trick to almost all of the improvements in Ratchet EXP (the EXP is for Experience, BTW) is fewer internal parts. Everyone wants lighter weight with the same performance, so DT redeveloped the internals of their hubs to use fewer individual components. Now just 13 components make up the hub (with the freehub body also including its two pressed-in bearings).

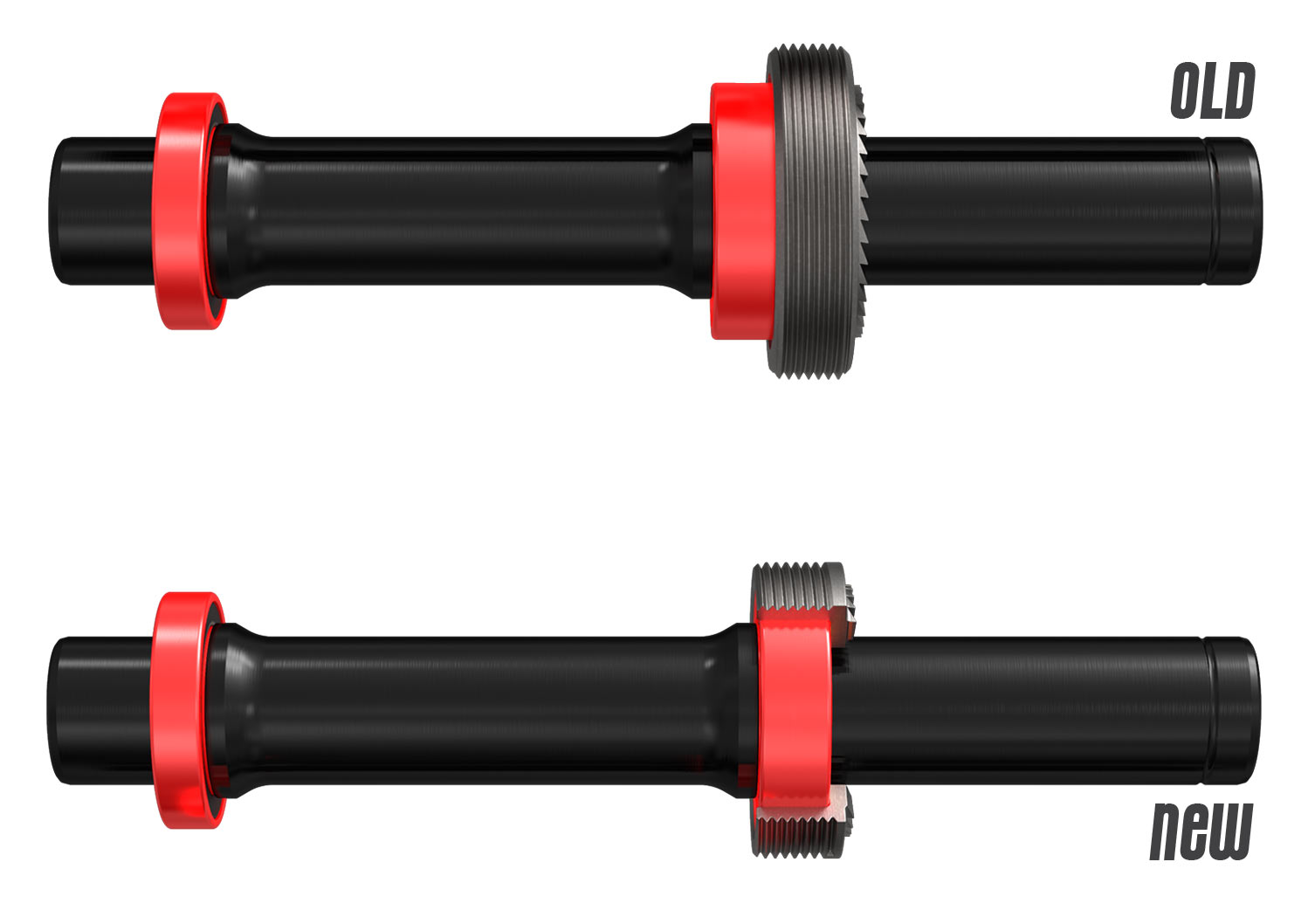

DT has also tucked in another easy maintenance trick with the new endcaps incorporating a notch/lip design that make it easier to remove them tool free.

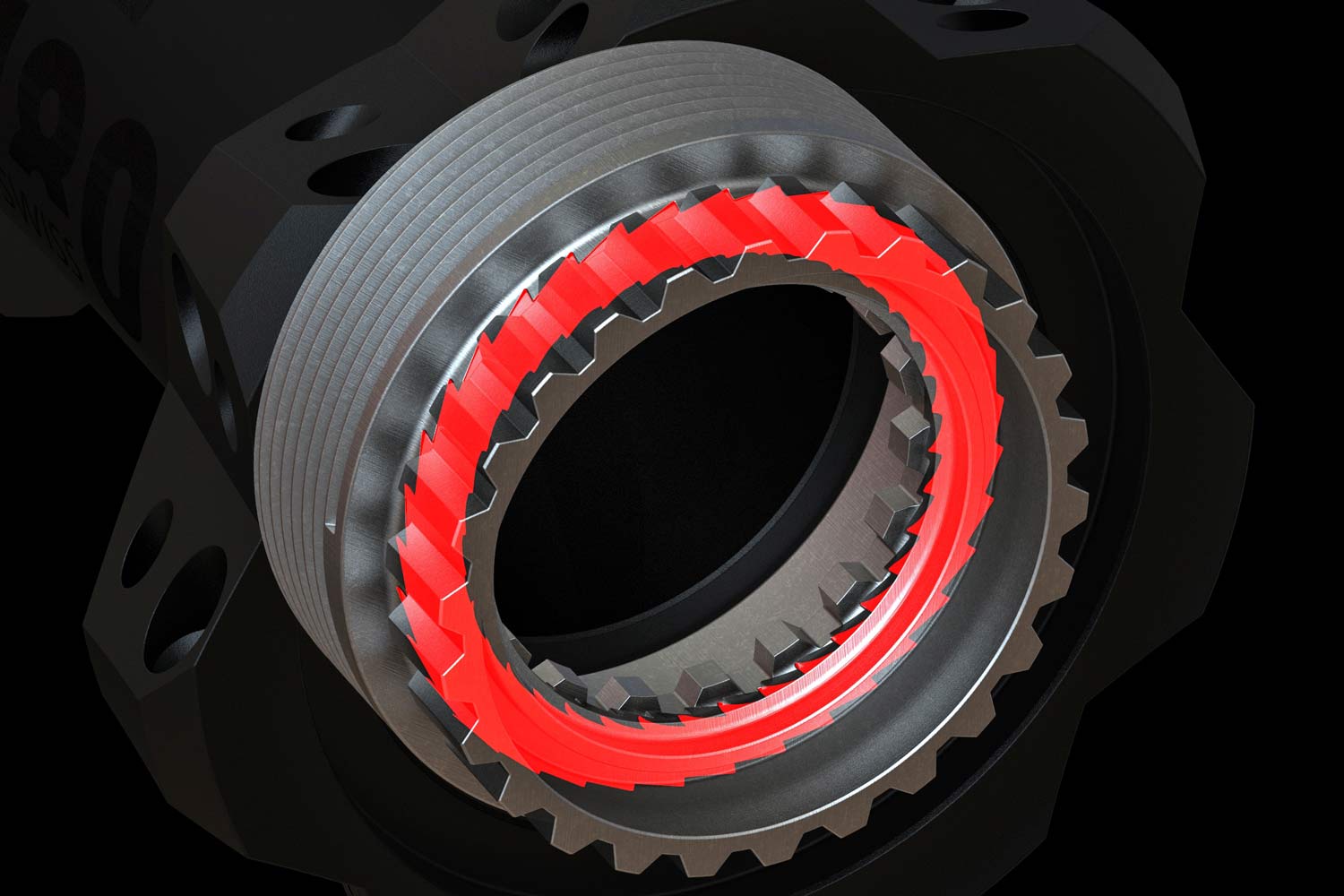

How did DT get rid of parts? By making the inboard ratchet & its threaded ring into a single, lighter element, one of the old conical springs also is no longer needed. That helps drop a little weight, but also results in more consistently precise placement of the new inboard ratchet. Threaded into the hubshell (with a new DT-made tool), the inner ratchet stays in place when the hub is opened up or you go to swap freehubs, making everything easier to access as well, with fewer parts falling out.

The new outboard ratchet ring is also now pushed against its opposing ratchet with a single cylindrical spring. DT says this results in faster, more complete engagement of the ratchet teeth for more precise contact, and therefore a longer lifespan.

Integrating the inner ratchet & threaded ring also allowed DT to tuck the primary driveside bearing inside the new ratchet mechanism moving the bearing about 7mm closer to the dropout. The result is a claimed 15% increase in stiffness. And while DT says hub stiffness was never a major issue for them, the extra stiffness means more precise alignment of the forces the bearing are exposed to, resulting in a significant increase in bearing durability.

As an example, DT says they hadn’t really ever supplied their top SINC ceramic bearings to their pro MTB teams, because they preferred the traditional reliability of precision steel bearings. But with these new Ratchet EXP hubs, Scott-SRAM has been racing now on the ceramic bearings and Schurter & Forster have already won the Cape Epic with the new hubs.

DT 180 hubs with Ratchet EXP options & tech details

DT Swiss’ overall concept for their hubs is to deliver high performance and durability, but never at the expense of usability. All major freehub body styles are available for the new Ratchet EXP design. While each build offers only the standard spec appropriate to the hubshell spacing & brake type, all of the new hubs can be converted to any of these six freehub bodies.

DT Swiss’ overall concept for their hubs is to deliver high performance and durability, but never at the expense of usability. All major freehub body styles are available for the new Ratchet EXP design. While each build offers only the standard spec appropriate to the hubshell spacing & brake type, all of the new hubs can be converted to any of these six freehub bodies.

The new EXP-equipped hubs all come standard with a 36 tooth ratchet ring for 10° engagement – what DT thinks is the sweet spot for high performance. More engagement point means smaller teeth for slightly decreased long-term durability, but also measurably increased drag. With that said, the recognize that some riders would prioritize engagement over the addition drag, so 54T rings are also available separately as an upgrade.

Availability & pricing

The new Ratchet EXP engagement system is first being made available exclusively in DT’s not-cheap, top-level straight pull 180 hubs with SINC Ceramic bearings.

Rim brake hubs are offered for road bikes with traditional road spacing and QR/RWS levers. The Road front hubs sells for $380/262€ with a claimed 87g weight and 20 hole drilling. The Road rear is $706/487€, just 175g and gets 24 holes. It can be spec’ed with Shimano 11s road, SRAM XDR, or Campagnolo.

A Centerlock Road Disc brake hubset is also available with 12mm thru-axles (100 & 142mm), again for Shimano 11s, XDR, or Campy. The Road Disc front hub sells for the same $380/262€ with 92g claimed weight and 24 holes. The Road Disc rear is $706/487€, just 180g and gets 28 hole drilling.

A Centerlock Road Disc brake hubset is also available with 12mm thru-axles (100 & 142mm), again for Shimano 11s, XDR, or Campy. The Road Disc front hub sells for the same $380/262€ with 92g claimed weight and 24 holes. The Road Disc rear is $706/487€, just 180g and gets 28 hole drilling.

Centerlock disc Mountain Bike hubs are also available, only with 15mm/12mm thru-axles & Boost spacing. They can be configured with traditional Shimano freehubs, the newer MicroSpline, or SRAM XD. The MTB front hub sells for $394/272€ at a claimed 94g with 28 holes. The MTB rear is $750/497€ at only 185g, again with 28 hole drilling.

All of the new 180 Ratchet EXP hubs are in production now, with consumer availability expected within the next month or so. While the new hub engagement mechanism is available now exclusively in these super premium pricepoint hubsets, DT suggested to us that they can be expected to trickle down through their hubs, replacing current ratchet hub internals with these high performing internals.