Cannondale builds on almost 40 years of crafting Advanced Aluminum Design alloy frames for their 13th generation CAAD road bike. The new CAAD13 is more race-ready than ever with aero-optimized tube shapes, modern wider tire clearance, rim & disc brake options, and improved rider comfort. Developed to toe the start line against much more expensive carbon bikes, Cannondale gives one more reason to first consider an aluminum road bike.

2020 Cannondale CAAD13 aluminum road race bike

Cannondale Advanced Aluminum Design (CAAD) again expands the possibilities of alloy road bikes in this v13 – claiming a faster, more comfortable, more capable lightweight road bike made from the 13th element on the periodic table. Cannondale built their brand on getting more out of aluminum than most bike makers, so we’re always keen on seeing where they take it next.

While alloy frames originally carried the stigma of a harsh ride, Cannondale have managed for years to create alloy bikes that bucked that trend. The latest CAAD13 promises to take it a step further by building in aero tube shaping, while preserving round tube weights and surprising comfort.

The heart of the CAAD13 in a new SmartForm C1 premium 6069-alloy that Cannondale says gives ultralight weight, plus high stiffness & strength through careful control of tube thicknesses throughout the formed tubeset.

The idea to create more aero tubing was a direct takeaway from the aerodynamic optimization of the latest SuperSix Evo.

This new integrated design CAAD13 uses the same basic truncated airfoil profiles as that premium carbon racer – at a much more attainable price point. Cannondale says they were able to maintain the same light weight & high stiffness of the old round tubes with these carefully shaped & butted aero shapes, while lowering drag by as much as 30%!

SAVE-ing your butt

The new alloy bike claims to also be more comfortable thanks to Cannondale’s SAVE system tech (remember that was the idea of built-in micro-suspension flex developed on their endurance road bikes as Synapse Active Vibration Elimination.) Beyond careful material placement in the new tube shapes, dropped seatstays are one key part of allowing a bit of vertical flex, as is the new full BallisTec carbon tapered steerer fork across all models.

But the CAAD13 also incorporates the same proprietary KNOT 27 aero seatpost & integrated seatpost clamp first debuted on the SuperSix Evo – said to be lighter & more comfortable than the previous SAVE iteration.

One other good way to add comfort (and control) is bigger tires. The new CAAD13 fits up to 30mm tires on the disc brake versions, and 28mm tires on rim brake models. The direct mount rim brake bikes are said to be limited by actual brake caliper clearance, so maybe some aftermarket brake option could even allow bigger tires on those as well – although the 28mm claimed clearance appears to be pretty conservative.

CAAD13 tech details

In addition to the aero shapes of the new bike, the CAAD13 adds the same multi-position, triple water bottle cage mounts on the down tube (check photo further up) that we see across most modern aero road bikes. A high position lets two bottles fit. But since most riders usually need just one bottle for racing, the lower position is always more aero with just a single cage.

The disc bikes also feature Speed Release axles for all of the strength benefits of 12mm thru-axles with quick QR access, which should still work with most thru-axle wheelsets.

All bikes get a new SwitchPlate modular internal cable routing system, BB30 bottom brackets, and full coverage fender mounts with a removable seatstay bridge mount.

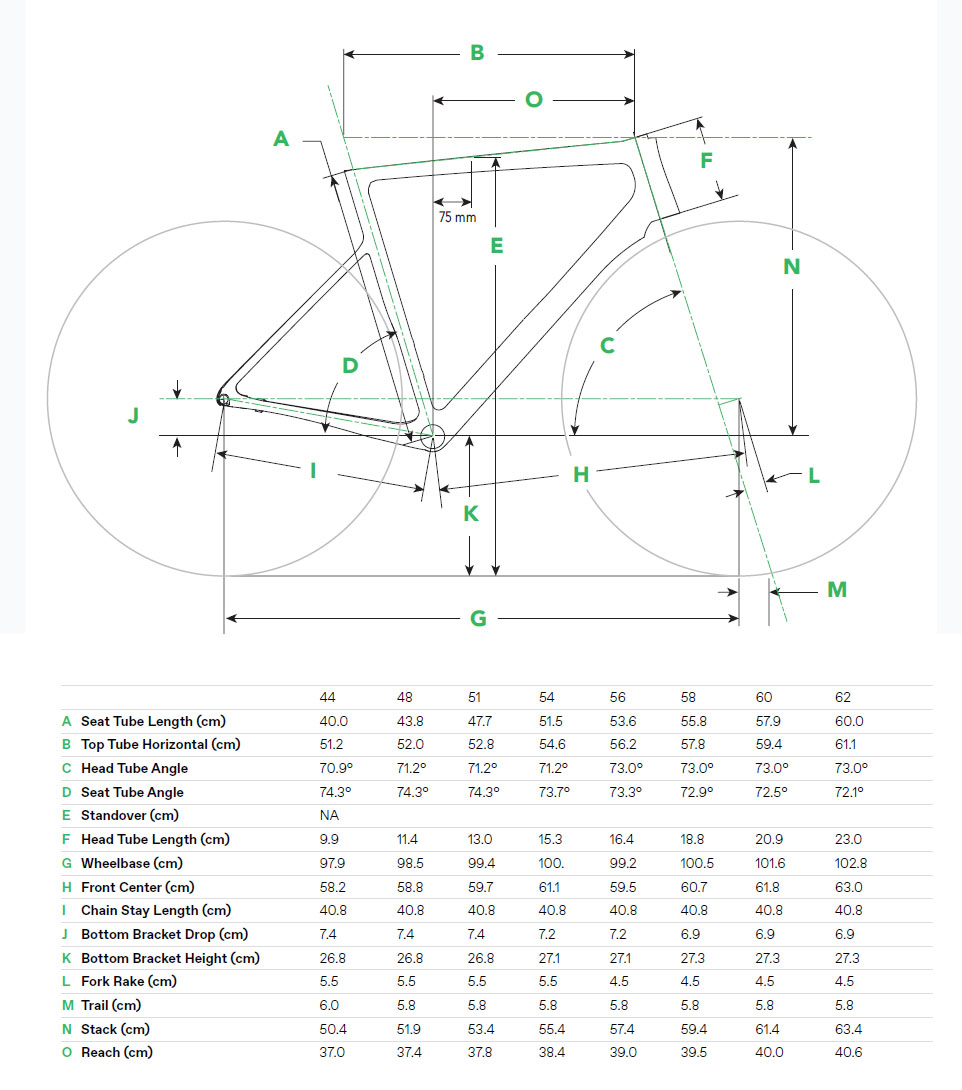

Geometry

Geometry of the new CAAD13 carries over the identical fit as the premium carbon SuperSix Evo – in eight frame sizes (44-62cm). Cannondale has always touted their CAAD road bikes as the everyman’s race bike, so they get the same low, aggressive race fit & precise handling as their top carbon race bikes. The CAAD13 does add a higher stack headset option too though, so you can get a more upright position without looking too out of place.

Pricing, Spec & Availability

The new CAAD13 road frames are offered in a number of complete rim & disc brake bike builds across many price points with 105, Ultegra, or Force eTap AXS – although a bit varied which version is available in which market. All can all be ordered today from your local Cannondale dealer.

The North America-only crit race-ready $5,750 CAAD13 Disc Force is by far the most expensive option with deep, wide HollowGram 45 KNOT carbon wheels and a carbon cockpit.

But stepping down to Ultegra is a big drop in price – 2,700€ for the CAAD13 Disc Ultegra in Europe, $2,400 / 2,100€ for the rim brake CAAD13 Ultegra with its wider global release.

A Shimano 105 group build is the most affordable. Disc brake CAAD13 Disc 105 bikes run $2,100 / 2,000€, while rim brake CAAD13 105 bikes are the lowest price of entry at $1,800 / 1,800€. A couple of women’s 105 rim & disc versions are also available that offer the same geometry & spec as the men’s bikes, with gender-friendly contact points.