The latest Specialized Project Black project has taken foam padding out of an S-Works Power saddle to create a 3D printed structure that is both lighter & more comfortable than a conventional design. The S-Works Power Mirror saddle is made up of a lattice of 14,000 liquid polymer struts that provide tuned support & flex to offer varying density and comfort that foam simply cannot match.

2019 Specialized S-Works Power Mirror 3D printed saddle

Project Black is how Specialized develops pre-production prototypes and tests them in the real world with their pro athletes. And while that normally means new tech that won’t likely see the light of day for quite some time, take a look at the model year of that heading above.

This new Mirror Tech saddle may be something they’ve just developed, but 3D printing seems to have let Specialized fast track the new saddle design, giving it a 2019 label and telling us that early production samples will be available in a couple of weeks.

Tech details – What is a 3D printed saddle?

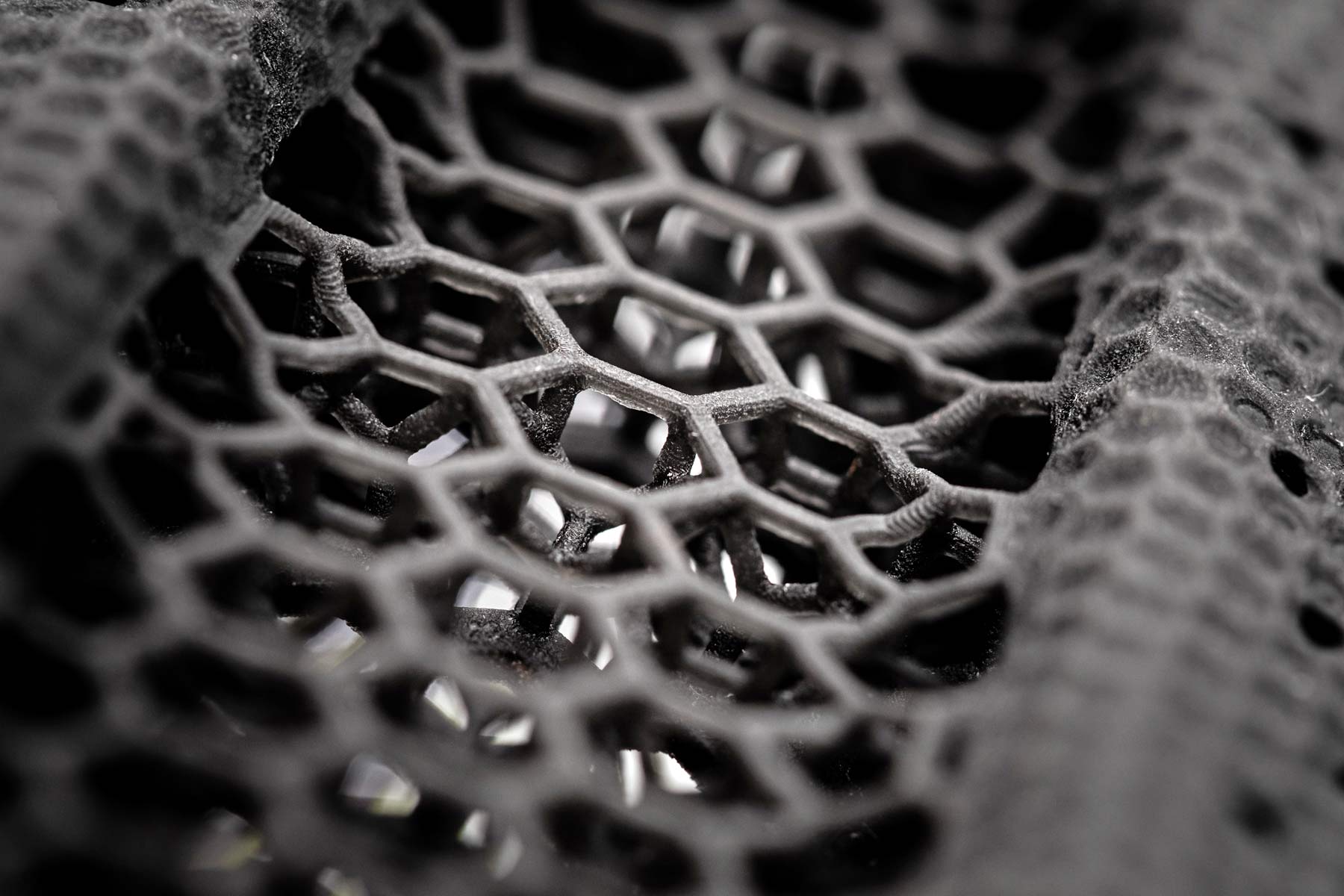

The technology that Specialized is using for these Mirror Tech foam-less saddles is called Digital Light Synthesis, which pretty much sounds like using intense UV light to solidify a liquid polymer to create this intricate structure, one tiny layer at a time.

By doing so, they created a lattice of 14,000 struts and 7,799 nodes forming the saddle shape. And each element can be ‘individually tuned’ to offer varying density throughout the saddle to mimic what you might do with multiple foam densities, but on a much more precise level. The process even results in the more-or-less closed top of the upper design, which is then bonded to a more conventional carbon fiber base with carbon rails.

That’s how you end up with a saddle with internal structure to offer more support under the weight-bearing sit bones, but more flexible comfort under soft tissue – with the possibility for nearly infinite variability. The material is also said to provide improved pelvis stability while pedaling AND improved vibration damping potential.

The all-new Mirror Technology uses a new 3D printed material that Specialized says “can replace foam in cycling touchpoints forever, delivering rider benefits that foam cannot match.” They see this as taking Body Geometry design to the next level, both for men & women-specific designs.

This S-Works Power Mirror saddle is only the first real application, but talk like that suggests it may make its way deeper into the Specialized lineup fairly quickly. Interestingly Specialized is showing the new S-Works Power Mirror on both road bikes above with team Bora-Hansgrohe, and with their Specialized Racing cross-country mountain bike teams as well (here on a BikeYoke Divine SL dropper post).

That reaffirms no issue with strength or durability for riding on or off-road. (Although, we imagine cleaning mud out of that open latticework could be a pain!) The new saddle was even raced at the Val de Sol XC World Cup by mountain biker Christopher Blevins.

Specialized say the new Mirror Tech equipped S-Works Power saddle is currently undergoing Project Black testing with their Decueninck–Quick-Step & Bora-Hansgrohe road, and Specialized Racing mountain bike pros.

Real-world availability

Even though Specialized gives the new S-Works Power Mirror a 2019 designation since it is being raced on now, they have not yet released any pricing estimates or concrete delivery timetable. The current pre-production saddles have been produced together with the Silicon Valley company that pioneered the 3D printing process, named Carbon.

In reality, consumer availability is slated for early 2020 in the new Power saddle. We do hope to get one before then, so we should be able to report on its comfort & performance before you can buy one.