For many riders, ENVE is a company that needs no introduction. But that doesn’t mean that there aren’t lingering questions related to their products. We asked you to submit your best questions for ENVE in regards to their mountain bike wheels and rims and you delivered. ENVE has answered the majority of them below, and they’ll be back in a few weeks to discuss the world of road and gravel, so start thinking about those questions as well!

I’ve heard that ENVE mountain rims are really stiff, what is the reasoning behind building a super stiff mountain wheel? – Paul

ENVE: This is a great question. First, you have to understand where the mountain bike world was when we started making mountain wheels in 2006. ENVE’s first big win was simply proving to the world that carbon was a viable material from which a mountain bike wheel can be made. 135mm spacing, tubeless, and 29” wheels were all still in early phases of adoption. We proved mountain wheels could be durable enough for daily use by the time we launched the first M Series in 2014. The main goals of that first M Series launch were:

- Solve all tubeless/burping issues – this is where hookless design was first introduced. Going hookless allows for more precise tubeless bead seats on a carbon rim.

- Make the rims tougher and stiffer – We did this, and it was needed because 135mm rear spacing w/ 29” wheels resulted in too much lateral flex. 12×142 was being introduced and this helped, but boost was not yet a thing, so the rim had to compensate for what was lacking in wheel bracing angles. The downside to these rim’s design was that the additional toughness began driving more wear and fatigue into the tires and the tubeless pinch-flat era began. Consequently, most of our competition is still making rims that more closely model the first generation M Series and all those issues we solved with our latest generation M Series persists to this day from those other brands. This is why many are moving back to aluminum and others are stuffing their expensive carbon rims full of inserts…

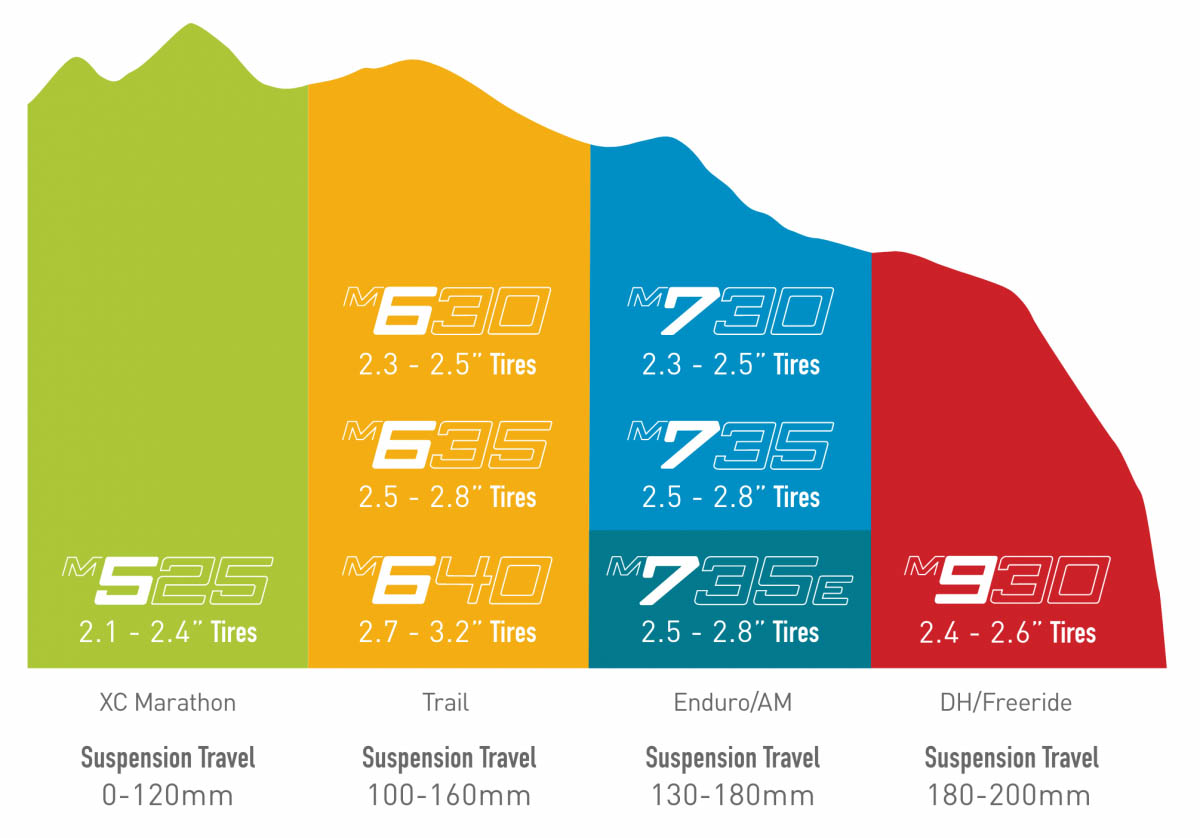

- Models purpose built for the needs of the discipline – The first generation M Series introduced the first tuned rim shapes and constructions for XC, Trail, Enduro, and DH applications.

Fast forward to the current M Series, Boost and Super Boost spacing are the norm today and rims don’t need to be as stiff as they once were. While we won’t say ENVE rims are in anyway soft, they are not as rough/harsh as some would have you believe. Each rim in the M Series family is purpose built for the application, so an XC rim is more compliant and lighter than an enduro/gravity rated rim. Each rim is very different. We are constantly testing and developing product with our athletes, and we make what helps them go faster. Our goal with rim stiffness is to strike the perfect balance between high-speed tracking for precise handling, and comfort.

When we hear from customers who are reporting that their M Series rims/wheels are too stiff or uncomfortable, 9 out of 10 times the customer has failed to account for additional rim/tire volume and is therefore running too high of tire pressure, and/or they have failed to adjust their suspension settings to accommodate for the higher performance mannerisms of an M Series wheel. When tire pressure and suspension settings are adjusted appropriately, you will find that an ENVE wheelset delivers a ride defined by confidence inspiring handling and you’ll go faster. Also, don’t forget the handlebar. The number one bang for the buck upgrade to your mountain bike in terms of handling and comfort would be to upgrade to an ENVE M Series handlebar.

ENVE’s use of internal nipples with molded holes supposedly lends greater strength. If this is a real advantage worth the cost why isn’t the use of internal nipples more widespread? Also does use of internal nipples compromise the use of other design features such as offset spoke holes? Internal nipples sure are a PITA to work on.

ENVE: First we’d recommend reading this.

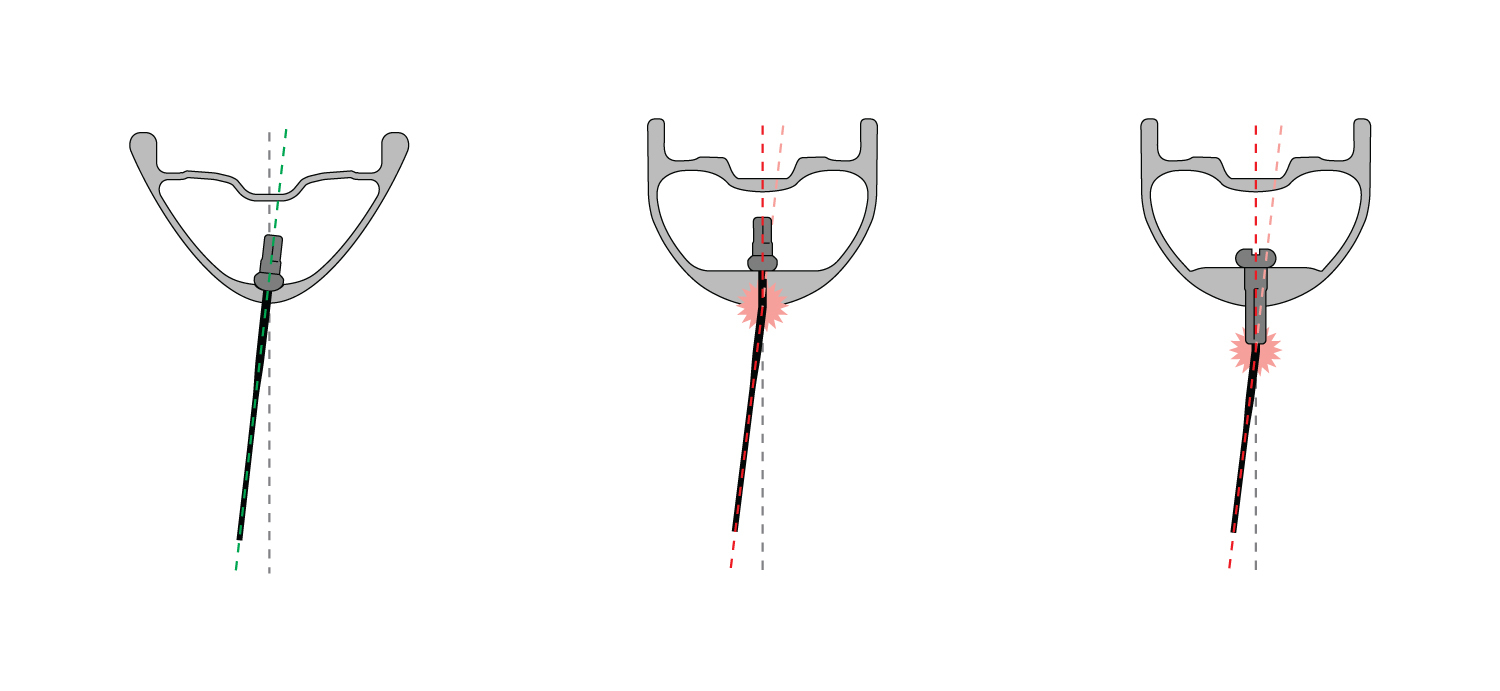

The foundation of the ENVE rim is the patented Molded-In Spoke Hole. This process of molding in the spoke hole allows for a stronger and lighter rim. If you don’t or can’t mold the spoke hole, there isn’t much reason to do internal nipples because you have to reinforce the rim and make it heavier anyway. Hence, why most don’t do it. The back side of each molded spoke hole features a conical seat that allows the internal nipple to articulate with the exit angle of the spoke which further prevents the likelihood of a prematurely fatigued and broken spoke. If we molded a larger spoke hole for external nipples, which we can do, the rim would gain weight as the larger spoke hole, despite being molded, would still require more carbon than the current internal molded spoke hole.

The whole objective of the design and our wheel build is to never have to true a wheel or to do so only at logical intervals like when you change a tire. If you’re breaking spokes, you generally have to remove the tire anyway to replace the nipple and repair the wheel properly. Internal nipples do not compromise rim design unless the rim is really shallow, in which case a super shallow rim does require the use of external nipples, to prevent the spoke from puncturing the tube or tubeless tape when impacted and compressed. As far as offset is concerned, the fact that our spokes and nipples can articulate to accommodate the exit angle of the spokes reduces the requirement of spoke hole offset. This is why most external spoke hole mountain wheels are and should be offset.

Why no asymmetric rims? – Sebastian

ENVE: We don’t have anything against spoke hole offset, it’s just not required with an ENVE wheelset given our rim construction provides all the stiffness we want, and our molded spoke holes w/ their conical nipple seat allow for the spokes to articulate and exit the rim at a friendly angle which is much harder to do with an external nipple rim.

Is there any reason that a mountain bike wheel set wouldn’t be good for gravel riding (given the correct hub spacing and end caps). I’ve noticed that a lot of mountain bike wheels (not brand specific) are lighter for less money than their gravel counterparts… does it all come down to hookless vs hooked bead, max tire pressure, and aerodynamics? Or is there some other reason not to use MTB wheels for gravel? [I typically run a 38mm tire, tubeless, at 40 psi] Thank you in advance! Michael

ENVE: This is a great question! The short answer is – ride quality. If you look carefully at many other brands “gravel” wheels, you’ll notice they are just rebranded XC wheelsets of days gone by, maybe with a different construction, but usually, just a rebadged rim being remarketed to gravel riders. Generally speaking, the two things that make an XC mountain wheel a good gravel wheel are impact durability and width. We certainly used to use and market the XC race oriented wheelset the M525 as a gravel wheelset. It performed really well, but it wasn’t a purpose built gravel wheelset.

So what did it lack? Primarily compliance/damping and ride quality. This is how the G23 was born. Because you don’t need the impact strength of a mountain wheel for gravel riding, we reduced the weight dramatically compared to the M525. Given that gravel riding happens primarily unsuspended, we wanted to build a lot of compliance into the G Series wheels, and if you were to ride a G Series G23 vs. the M525, you would feel that the differences are not subtle.

Gravel is its own discipline and as such deserves dedicated technology. As for aerodynamics, if the tires you are running have tread on them, you can pretty much kiss any aerodynamics goodbye. We’ve found that weight savings and compliance are priority for fast gravel riding. Side note: If your definition of gravel riding is shredding mountain bike trails on your gravel bike w/ a 50mm or larger tire – you should probably be on a mountain wheel.

I currently own 2 sets of M525s, 4.5 AR and 5.6 disc. In the past I also had some M50s, and on this rim I had a tire much later declared incompatible with hookless rims by the manufacturer blow off the rim (despite my opening a support ticket once the manufacturer announced this, ENVE still doesn’t list this tire line as incompatible). ENVE’s recent blog post around hookless rims put forth that hookless is inherently better. However other than manufacturing ease/cost and maybe durability the article offered little to no data on how or why hookless is better from a tire/rim interface, which I thought was the point of the article. I would like a better explanation of why ENVE considers hookless “better”. – Joel

ENVE: Joel, Sure thing. Simply put, hookless isn’t the problem. We are at a unique crossroads as it relates to the wheel and tire interface. Wheel technology has advanced much quicker than tire technology and as a result, the skeletons in road/gravel tubeless closet are coming out. The point of the hookless article was to shed light on how the tubeless interface is supposed to work. How it works in every other application outside of bike. That is, tubeless tires are to establish a seal on the rim’s bead seat diameter, not on a hooked bead. The only reason a tire bead should interface with a hooked bead is if the tire is stretching off the rim. If you take that stretchy tire and put it on a hookless rim, it will blow off. So, why hookless? You mentioned that there are efficiencies in manufacturing and that is true, however, what hookless really allows ENVE to do is mold rims with more exacting tolerances in the rim’s bead seat diameter. In other words, to ensure the safest and most reliable tubeless set-up, we choose hookless. As mentioned previously, we are at a crossroads, and the encouraging news is that there is no shortage of tire manufacturers who get it, the proof being in the ever growing list of “recommended/approved” tires on our list of tires approved for use with our hookless rims. We are working as closely as possible with all the tire manufacturers so that we can to ensure that their tires are constructed in a fashion that is suitable and safe for use with modern wheels using hookless construction.

For MTB hubs, my bike (Scalpel SE) has boost front, non-boost rear. What do you recommend for ENVE rear wheel/hub combo that will maximum flexibility to adapt to boost rear in the future if I get a new frame? I would like to stay with center lock rotors, is that possible? Thanks for making awesome products! -Sunny

ENVE: Sunny, unfortunately, your best option would be to sell the complete bike with its dedicated wheelset and start new when/if you get a new bike with boost spacing. There are spacer kits in the world that can convert 142 to 148, but these are not ideal setups in our opinion.

Context: M40, prebuilt by ENVE, owner @ ~165lbs ride weight in the PNW/Vancouver Island. Primarily AM/Enduro trails with low to moderate hits, gaps, tables, etc. at ~1 – 5 hrs. per week, year round. I started popping spokes in my rear, and – despite the local wrenches working on it to balance tension, etc. with replacements – the popping continued. After the fifth time of having my ride curtailed/toned down due to a spoke pop, the wrenches said ‘ENVE’s are stiff, and it isn’t uncommon to have to re-lace the whole wheel after a season or two’

A chunk of service and material fees later, I have my re-laced wheel – but am seriously considering whether I will sign up for another round on this, apparent, two-year tear-down/rebuild program inherent to ENVE. Is this normal?

ENVE: This is not a normal experience; you should not experience broken spokes at any time with an M Series wheelset with the exception of say unlucky wheel intrusions that cause a broken spoke. But broken spokes are not the norm… If this is happening, it is more likely than not the result of a bad or compromised initial wheel build. There are two things that can cause a spoke to break in the manner you’re describing: 1) spokes were too short or 2) less likely, but possible, one or more of the molded spoke holes are uneven which can cause additional stress on the spokes. If the original wheel build came from ENVE, we’d have asked for the wheelset back to investigate and a rebuild would have been covered under our factory warranty assuming we found something wrong like noted above.

Does ENVE have data on the longevity of the pre-built M-series wheels under ‘standard riding conditions?

ENVE: No empirical data because every rider’s style, skill level, and terrain vary. We offer a 5 Year Factory Warranty which covers defects in materials and workmanship as well as Lifetime Incident Protection for original owners. Lifetime Incident Protection covers incidents – i.e. impacts while riding/racing, crashing, casing, etc… Normal wear and tear is not covered under this program. The thing with carbon that makes it so special is that it doesn’t fatigue like aluminum. In other words, a rim that has 10 years of riding on it isn’t any more prone to crack after 10 years, than it was after 10 rides. To give you some data, since we launched the current M Series lineup in August of 2017, we see < 2% warranty rate for impact damaged M Series rim across all models.

I’m not trying to sound rude when I ask this question and I apologize if it comes across that way, but why are ENVE wheels so expensive compared to other offerings on the market? Will we ever see a budget (i.e. sub $2,000) option from you? Thank you for taking the time! – Nick

ENVE: Nick, no offense taken. It’s fair to ask this question and the easiest way for someone to understand is to simply tour our facilities here in Ogden to realize how much goes into making an ENVE wheelset. Our doors are open if you’re ever driving or passing through. But since that is easier said than done, here’s what you see if you came here. Manufacturing carbon fiber is a craft and one that is highly dependent on skilled manual labor. In other words, there are very few processes that can be automated. We have roughly 150 employees working every day to manufacture the wheels we offer. Walk into any other wheel brand with the exception of a couple and their company consists of 5-20 people mostly dedicated to sourcing and selling the products they brand. As it relates to a lower price point wheel, we are not opposed to delivering a less expensive offering; we just want to do it the ENVE way. Which means, we don’t want to make something less expensive just for the sake of offering something cheaper. Anything that says ENVE needs to be a premium product even at a lower price point. If we do come out with a sub 2K price point, rest assured it will be the best sub 2K wheelset on the market.

How does ENVE plan to remain competitive now that carbon rims are a commodity? How does ENVE support their value proposition at $1000 per rim vs Light Bicycle at $269 (high end Chinese carbon) per similarly high quality rim now with North America support & 5 yr. warranty (+$50 for lifetime)? – Fred

ENVE: This is a great question and certainly one that we ask ourselves often. At this point, ENVE has been making carbon mountain wheels for the top level of the sport for over 12 years and counting. Over that period, we’ve made literally every rim right here in Ogden, UT. We have a vast knowledge-base of what makes a great mountain bike wheel, having prototyped literally 1000s of rims and concepts. It is rare that another manufacturer launch a carbon wheel design that we haven’t already tried. If you look at the lower cost competitors to ENVE on the market, the only technology they share in common is the fact that they’re made out of carbon.

The current M Series wheels possess features, benefits, and a dynamic ride quality that you can’t get anywhere else. For example, M Series wheels feature one-of-a-kind anti-pinch flat technologies and greater strength to weight ratios than anything else we’ve tested, and we test it all… If rim and tire protection are things you want, the only solution if you’re not riding ENVE is to either run tire inserts to mitigate pinch flats, run heavier tires, run too high tire pressure, or some combination therein. Ironically, by the time you buy inserts and replace a half dozen tires, you could have just bought ENVE. While anti-pinch flat technology may not seem like that big of a deal, it is, because if you can eliminate and reduce the propensity of the catastrophic tubeless pinch-flat, you can now run lower pressure for better comfort and traction and therefore gain confidence and speed. You also have the opportunity to reduce unsprung weight further improving your suspension’s performance and the ride experience. Further, because we conceptualize, prototype, and manufacture all our rims here in Ogden, UT we can test and prototype more rim designs and constructions than any brand who outsource manufacturing overseas could dream of.

So, to remain relevant, the product must be the best, which it is. Second, if something goes wrong, it is our goal to provide the best customer service in the industry. We’re not perfect yet, but we won’t settle for second best.

Do you use pressure to cast your rims, and if so what psi? – James

ENVE: Yes, manufacturing carbon requires heat and pressure. As far as the details go, those fall under the category of trade secrets…

Who’s a stronger rider? Neil Pantone or Jake Shirley? Also, is gravel dead yet? – Chuck Norris

ENVE: Chuck, Who is stronger: Jet Li or Bruce Lee…?

Learn more at Enve.com.

Got a question of your own? Click here to use the AASQ form and submit more questions for ENVE. We’ll have ENVE back in a few weeks to answer all things road and gravel related, so get those questions in now!