I know what you’re thinking. Another bike brand launching their own wheel line? But before you write off Revel Wheels as just another carbon-fiber-copy, you have to check out the technology Revel is using in their rims. It’s exciting enough that Revel Owner, Adam Miller, says that this is the most exciting project he’s ever been a part of. Both a process and a material, Fusion-Fiber represents a new way of looking at composite construction that claims to be stronger, lighter, more cost effective, better riding, 100% recyclable, and all made in the USA by CSS Composites.

Like some of the best stories in the bicycle world, the partnership between Revel and CSS Composites started with a chance encounter on a mountain bike trail in Ogden, UT. At the time Joe Stanish (now the COO of CSS Composites) was the VP of operations at ENVE composites, while Adam was staring down his 10-year plan to eventually get his third, and most ambitious, bike company launched with Revel Bikes. Fast forward to early 2019 when Joe approached Adam with the idea to create the first mountain bike rims using Fusion-Fiber – the rims that would eventually become the Revel RW30.

Forget Epoxy

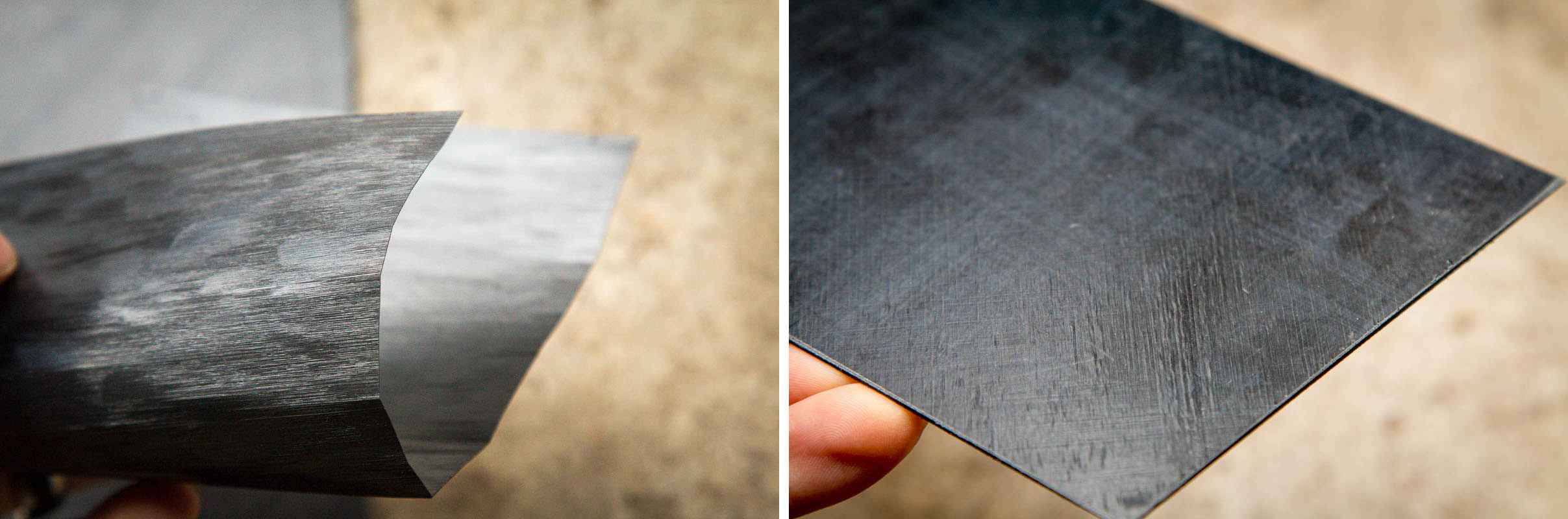

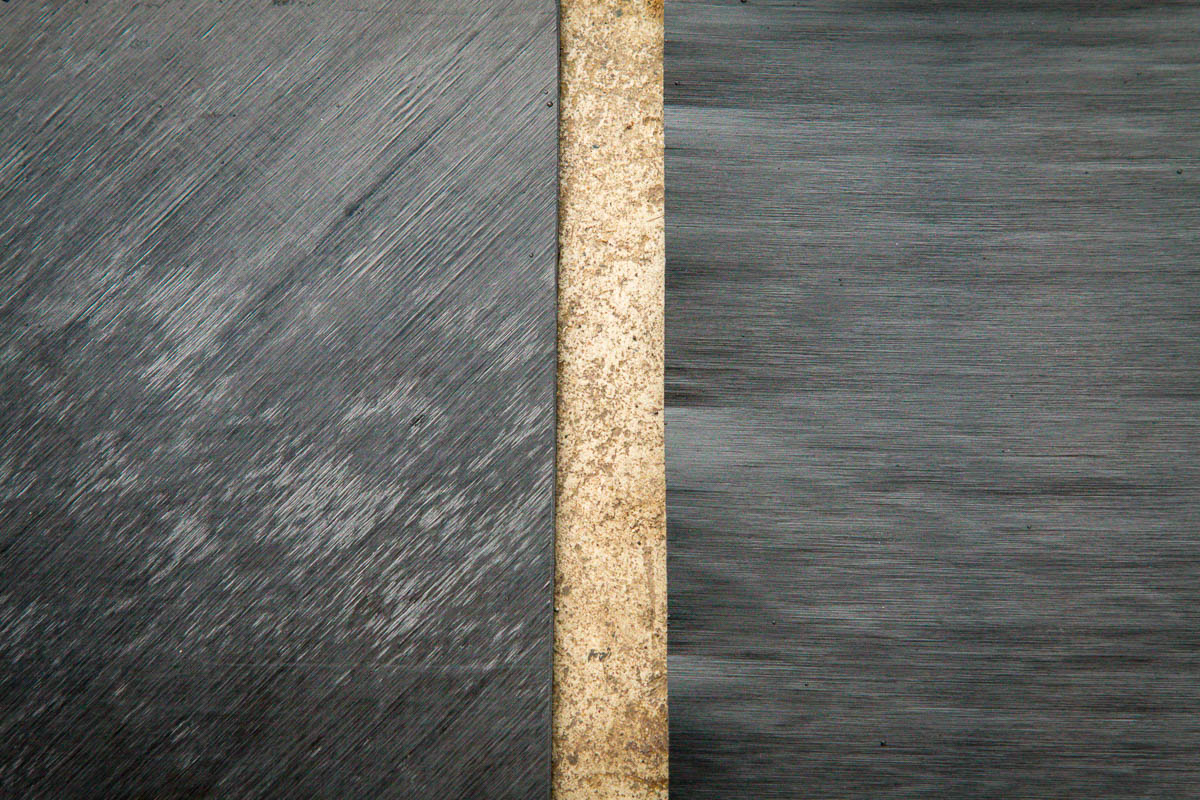

Where traditional carbon fiber relies on epoxy resin as a curing agent, Fusion-Fiber completely eliminates the epoxy resin. Instead, a nylon polymer curing agent is used which results in a number of benefits. Compared to an epoxy based composite, Fusion-Fiber is supposedly better for both the workers building the rims and the environment itself.

Without epoxy, the raw carbon fiber isn’t as sensitive to outside contaminants like pre-preg carbon, and Fusion-Fiber doesn’t have to be refrigerated either, resulting in a longer shelf life. With flex built in at the “between-the-fiber level”, Fusion-Fiber also claims to have the ability to dampen the ride feel, resulting in less trail buzz transmitted to the rider.

The list goes on – rather than relying on humans to lay-up and cross-ply the long fiber German and Japanese carbon fibers, this process is done robotically. That results in a much more consistent final product, which is enhanced by a curing time of just 20 seconds. Compare that to the ~45 minute curing time of a standard rim with pre-heating and cooling on either side. After this flash cure, the rims pop out of the molds without the need for any additional sanding or a clear coat. All that’s left to do is apply decals and build the rims. Pretty impressive.

What about the weight? According to Adam Miller, the Fusion-fiber material is almost exactly the same weight as an epoxy resin based carbon of similar modulus. There’s even the potential to make products even lighter due to the material’s increased strengths. Adam didn’t provide specifics, but claims that they have bench marked the rims against their major competitors and the Fusion-Fiber rims tested better in terms of durability across the board.

Broken? Why not Recycle?

Even with a more durable rim, shit happens, right? In the event that you manage to break one of the Revel rims, things get even more interesting. Instead of just tossing yet another rim into a landfill, Revel Wheels has the ability to recycle a broken rim and give it new life. Obviously, once you chop up a rim that was built with continuous long fiber carbon, it’s no longer long fiber. So while the recycled rims won’t end up as a new rim, they will end up as other products which can be manufactured using the short fiber carbon.

Better still, if you manage to break a Revel Wheel, the company has your back. Each rim or wheel includes a lifetime warranty and crash replacement policy to the original owner. Not only that, but Revel will send you out a set of loaner wheels to use while they rebuild your existing wheel with a new rim. They’ll even cover shipping both ways.

Rim Details

As far as the rim design itself, the first Revel Wheels product is the RW30. Rated for enduro or trail riding, the RW30 features a 29mm internal width and 35mm external width. Available in either 28h or 32h, each rim is tubeless ready with a hookless design and is optimized for 2.3-2.6″ tires.

Actual Weights

Offered in 27.5 or 29″ sizes, the claimed weights for a single rim are listed as 440g for 27.5 or 480g for 29″. As for complete wheelsets, claimed weights are given as 1730g for a 27.5″ I9 Hydra Boost and 1840g for the same build in 29″. On our scale, the 29″ set came in at 1857g with tape and valves, so the wheels are likely under the claimed weight.

Pricing

The RW30 will be available for purchase as a rim only, a complete wheelset, or as an upgrade for a new Revel mountain bike. The rim only option is priced at $699 which includes rim tape and valve stems. Complete wheels start at $1975 with Industry Nine 1/1 hubs, Sapim D Light spokes and black brass nipples. Jump up to $2200 and you’ll get a complete wheelset with the new Industry Nine Hydra hubs. Both complete wheelsets are built with 28 spokes front and rear, and include XD or Shimano Microspline freehub options.

If you’re purchasing a new Revel bike, the I9 1/1 RW30 wheels will be included on any Revel X01 build. From there, any SRAM AXS XX1 build will include the I9 Hydra RW30 wheels as stock. Even if you’re purchasing a complete bike with the SRAM GX build, you can upgrade to the RW30 carbon wheels starting at $1100.

Availability

With the introduction of Revel Wheels, any Revel Bikes dealer is automatically a Revel Wheel dealer as well. But Revel is also hoping to set up new dealers – even if they want to just be wheels only. All of the wheels and rims are available today.

Stay tuned for a first ride review coming up soon!