Hailing from east coast mountain bike destination Brevard, NC, upstart Gulo Composites is weaving its way down the road & trail with unique, US-made carbon spokes.

They’re paired to their carbon rim design and custom hubs, rounding out a complete wheel system. Offered in road, gravel and mountain bike variants, they combine aerospace materials in a lightweight, tough package. Here’s how they’re made…

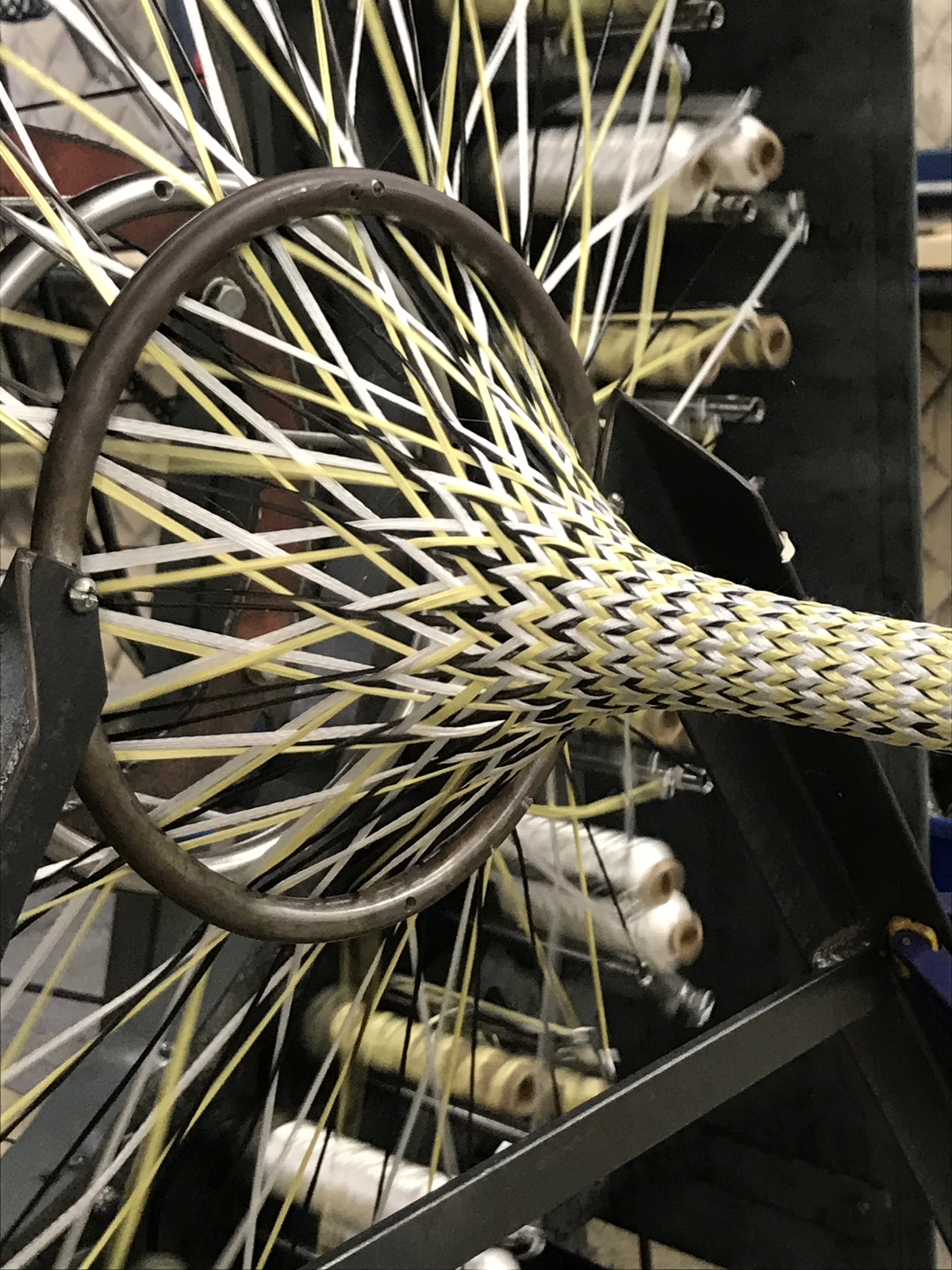

Gulo’s triaxally braided carbon fiber spokes

Quick background: Gulo’s parent company, Keir Manufacturing, has been in the technical ceramics & abrasives business for almost 40 years, serving a wide variety of industries. About 10 years ago, Keir acquired a carbon fiber business from an aerospace company, which got them in the composites game. Their main claim to fame was a technological process called triaxial braiding, in which they create 3-dimensional carbon structures from the fiber up. This lets them, quite literally, braid and weave specific shapes and designs.

Brevard being a mecca for cyclists, they landed on the idea of making a braided carbon fiber spoke. After a hundred or more iterations, the G1 spoke was born. They claim it has far greater impact resistance and resilience than steel spokes, but at 40% of their weight. Claimed weight is just 2.6g per spoke.

Their setup uses multiple spools and bobbins of individual fiber tows (each tow, or strand, is comprised of 10,000 or so fibers) that are able to rotate in sets around other sets, creating a tube. Whereas regular carbon fiber is woven into a flat sheet, this is woven into a three-dimensional shape.

What about the rest of the wheel?

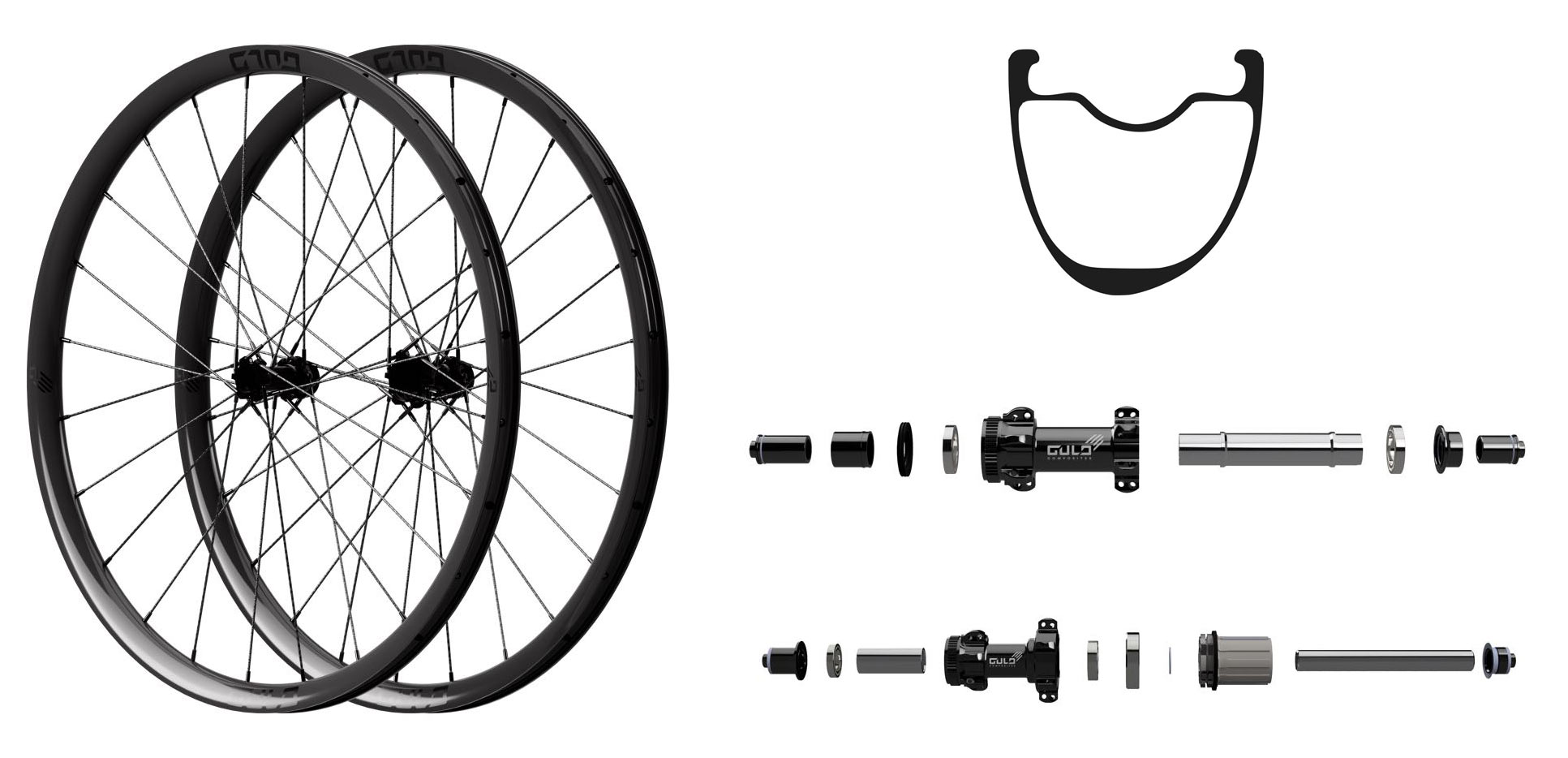

Their wheels are designed as a system, using custom tailored components so that they all work together to equal more than their parts.

The hubs are machined from 7075 alloy, with threaded holes aimed directly at the rim’s spoke holes. They create a straight pull design, minimizing stress on the spokes at both the rim and hub. The spokes use an aerospace alloy head on both ends, bonded onto the carbon spoke.

They have a 6.66º rotational engagement, using six pawls in two sets of three. Steel bearings and your choice of XD, HG and Microspline freehub bodies for mountain bike. For Road, they offer Shimano 10/11, SRAM XDR, and Campagnolo.

The rims are made at a partner factory in China, using their own specifications. The layup, resins, and drilling angles are unique to them. And they drill the spoke holes to align with the spoke, so you get a truly straight pull.

The mountain bike rims come out of the mold as smooth as you see them in the photos, there’s no sanding or finishing work required. UV protection is blended into the resin, so there’s no need for any clear coat. The road and gravel rims use different molds and resins and do get a bit of sanding and finishing for now…they do have a new gravel rim coming soon that’ll use the same process as the MTB rims.

Long term plans are to open their own molds, then eventually move the rim production in house, in the U.S. And they’re working on expanding the capacity of their braiding process to other components, too. While that plan does include rims, which would mean continuous fibers and no cut pieces of carbon sheets, they don’t want to be just a wheel company. But these plans are years in the making. For now, here’s what’s on offer…

Gulo Mountain Bike Wheels

They offer two different mountain bike wheelsets, the trail-worthy GME-30 (shown above and in detail photos), and the XC GMX-25. The number refers to the rim’s inside width, and they both use a hookless design.

Claimed weights are 1,460g (GME) and 1,290g (GMX). Both are 29er only, with Boost spacing, and 24 spokes per wheel. The XC wheelset has a 220lb (100kg) rider weight limit.

They ship with rim tape and valves pre-installed, and you can choose between black or gold spoke ferrules. Retail is $2,360 (GME) and $2,525 (GMX).

Gulo Gravel Bike Wheels

The GRX-SL wheelset is ready for gravel and cyclocross, and you can get them with 9mm QR, 12×100 and 15×100 front axle setups. For the rear, there’s QR, 12×135 and 12×142, giving older bikes a great upgrade option. They’re disc brake only, though, so you’ll at least need that on the bike.

Rims are 22mm wide inside, and claimed weight is 1,275g. Retail is $2,625 for the set, tape and valves pre-installed.

Gulo Road Bike Wheels

With the same hub endcap options as the gravel wheels, they give you two depths for road. The GRA-46 (on left) is 46mm deep, 21mm wide internally, and retails for $2,575. Claimed weight is 1,365g, making them among the lighter options for that depth.

The GRD-36 wheels are 36mm deep and share the 21mm internal width. Both use a hooked bead design, like the gravel wheels. Claimed weight is 1,320g, retail is $2,490.

They’re small batch, so inventory comes and goes…check their website for details. We’re reviewing a set of the GME-30 trail mountain bike wheels and will post our thoughts later this summer.