The bikes of the future are being created today. Really, that’s how it’s always been, as it takes years for a new bike to go from a drawing to a finished product. But Decathlon is looking even deeper into the future, and they’re doing so through an intriguing partnership with Autodesk.

We’re sure that Decathlon is far from the only brand using Autodesk, but a recent bit of news focused on what the French retailer has been up to. As part of a goal to have all of their products “eco-designed” by 2026, Decathlon states that their teams “are always exploring more sustainable, better-performing designs. We have entire product design teams working to push the boundaries when it comes to performance, affordability and sustainability. So far, the results have been promising, so our team is conducting additional research.”

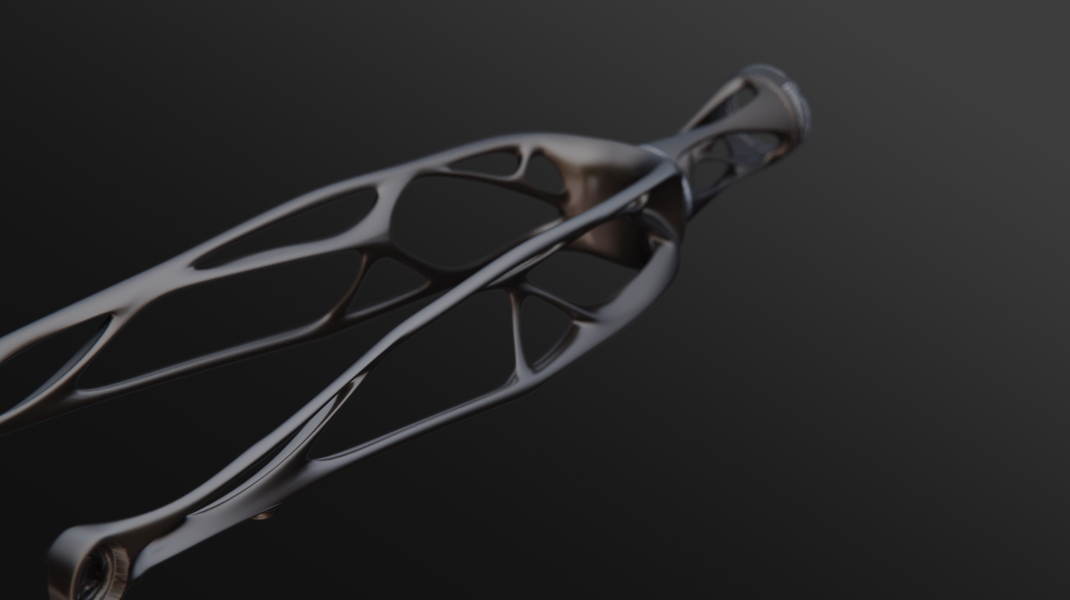

That research seems to indicate future plans to create 3D printed aluminum frames, that could even be customized for individual riders. Using Autodesk’s Generative Design technology, artificial intelligence can be used to rapidly create many solutions to how you can create a bicycle frame to withstand the forces normally experienced. While these options may not be feasible with traditional construction methods, the ability to 3D print an entire frame would open up a world of possibilities – giving us wild potential products like the fork shown above.

Decathlon is quick to state that this won’t affect their current bicycle line up in the short term, but it could have a big impact on the future. Say, if the technology allows for aluminum frames that are lighter and better performing than carbon, then it has the potential to reduce the raw materials needed, cut down on shipping those materials around the world, and create bicycles that are easier to recycle at the end of their useful life.

Decathlon is quick to state that this won’t affect their current bicycle line up in the short term, but it could have a big impact on the future. Say, if the technology allows for aluminum frames that are lighter and better performing than carbon, then it has the potential to reduce the raw materials needed, cut down on shipping those materials around the world, and create bicycles that are easier to recycle at the end of their useful life.

For more, check out the full release from Autodesk at the link below.