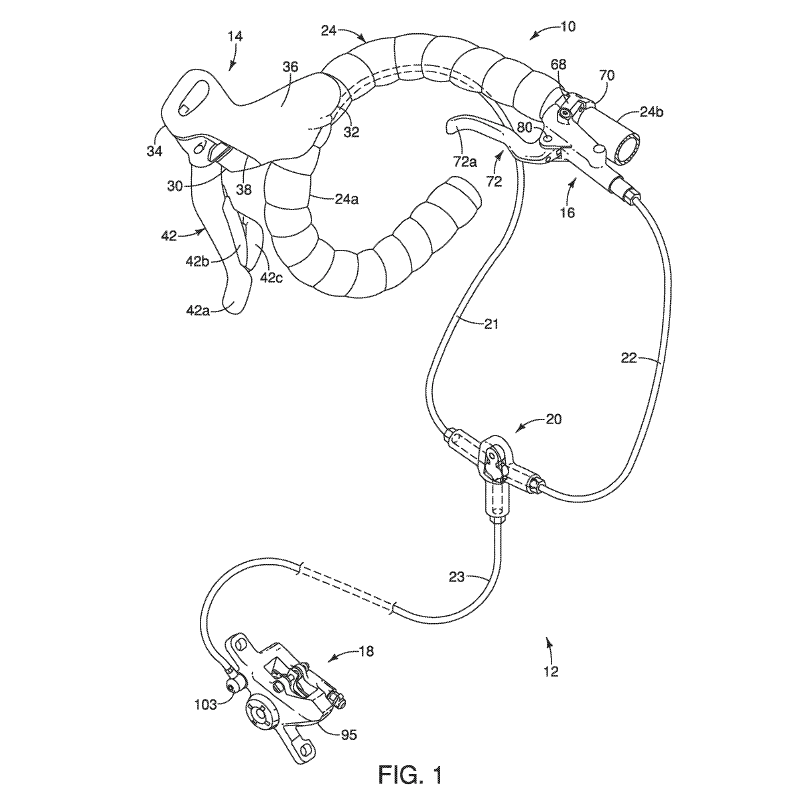

My long-term review of Shimano GRX Di2 will be hitting the airwaves here at Bikerumor very soon. In it, I mention the notable braking power of the sub-levers that live on the bar tops. These levers now sit in line with the main brake levers and the hydraulic fluid from the master cylinder flows through the sub-levers.

With the T-junction outlined in this patent, each lever can operate independently of the other. And, notably, only one of the brake levers requires a fluid reservoir.

Separating GRX’s integrated brakes

Shimano devised an excellent in-line solution for adding a braking position to your handlebars for its GRX groupset. The sub-levers live on the bar flats and give you a great braking feel without having to plant your hands on the hoods.

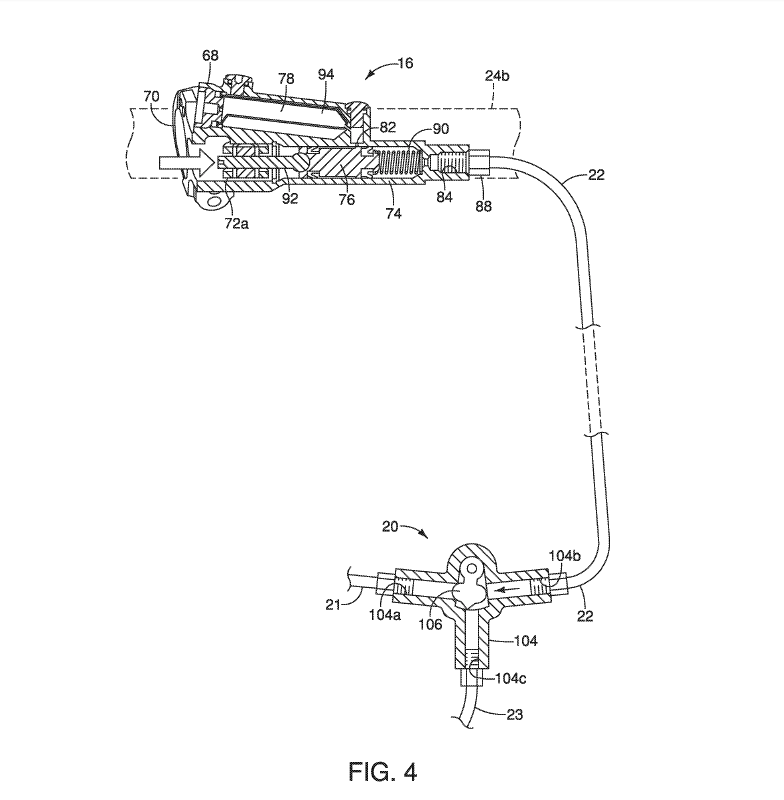

Now Shimano is refining the braking dynamics of the system by adding an apparent inline junction. This T-shaped junction connects the hose from the sub-lever and the main brake lever, and connects both via a single hose to the caliper.

The question is, why add this extra component to a system that already works wonderfully?

But why?

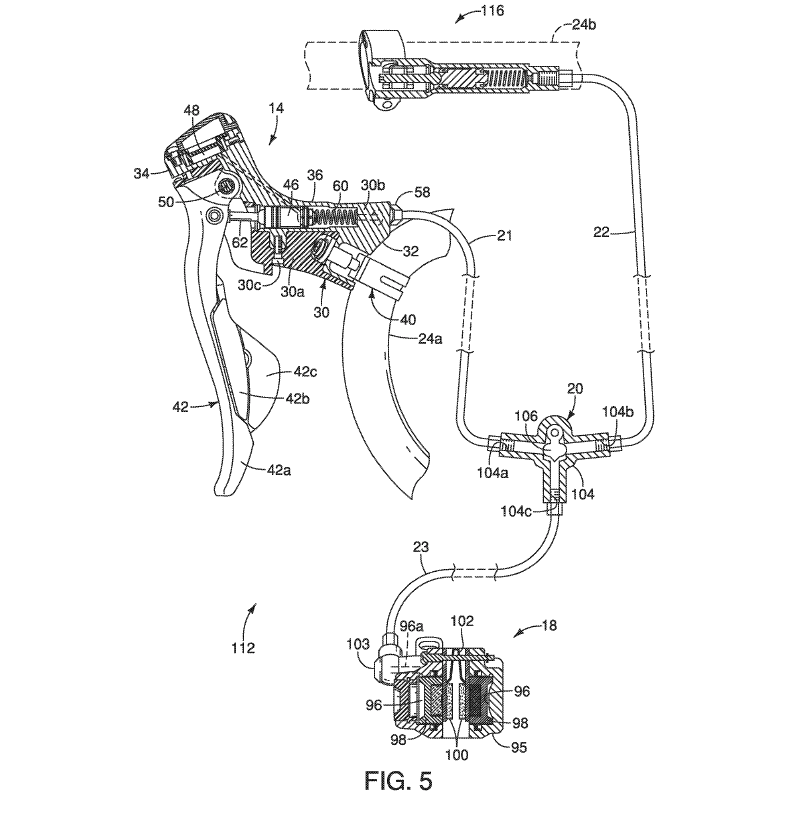

As Shimano states in the patent, the patent outlines a system in which “an actuating device and an additional actuating device can be selectively used to operate a single hydraulic operating device.”

The junction features a pivoting guide inside that essentially closes off one of the brake master cylinder systems when the other is activated. For example, if you’re using the sub-lever to actuate the brake, the pivoting guide will swing to close the hydraulic fluid in the main brake lever’s system before it meets the junction. And vice versa: actuating the main lever will shut down the fluid system from the sub-lever.

Notably, the pivoting guide prevents whichever lever that’s not being activated from losing hydraulic pressure.

You can also use an open hydraulic system lever with another open hydraulic system lever, or you can use an open hydraulic system lever (with a main reservoir) and a lever with a closed hydraulic system. An open system features a reservoir of fluid and air that accommodates heat expansion. A closed system lever features no reservoir, just a piston that pushes on a fixed volume of fluid.

T-junction benefits

That means you can use a different lever — rather than the GRX sub-lever — within the system. You could, for example, use a Shimano Deore brake lever as your sub-lever, which offers a larger brake lever and some more adjustment options.

And you should be able to configure the actuation ratios of each lever independently. You can make the sub-levers more positive and sensitive, for example, than the main levers.

A guess, based on my GRX experience

The second reason is a conjecture, and it addresses something I experienced in my year-long review of GRX. The problem: if you decide you don’t want or need the sub-levers after you’ve installed them, you’re going to have a bit of surgery to do in order to remove them. From there, you’ll need to re-run a hose just for the brake levers at the drops.

While the sub-levers feel great and do exactly what they promise, I found I didn’t really need them. Yet they’re still on my handlebars because I don’t want to do the surgery.

The solution: The T-junction. Of course, this assumes it’s possible to simply block off the input port that would otherwise accept the sub-lever’s hose. You can basically install this T-junction into the hose run between your main brake lever and the caliper. Then, if you decide to use the sub-levers, you can simply run a hose between the sub-lever and the T-junction in the main hose run.

At least that’s what I’m hoping you can do here. It certainly would be nifty to be able to add the sub-levers for a race or long ride when I want them, and remove them the rest of the time.

But primarily, it seems the GRX T-junction is designed to allow you to tailor the braking feel between the two brake systems and open up more options for various lever configurations (like using a closed or open system lever).

Patent research assistance provided by Wheelbased.com. Check them out for deeper dives on some of these patents and more.