Ibis claims that when they started their Carbon 831 Lab, they didn’t initially set out with the goal of in-house manufacturing. Initially, they simply wanted to use it as a tool for prototyping and development, but along the way, they got curious. What is possible when it comes to making carbon frames in the USA? What would Ibis have to do to make it feasible?

They set out to find that answer with a trial run of a single size for a single model. Those Small Ripleys were a success, and it led Ibis to pursue their first model completely built in-house – the all new Ibis Exie.

Now Ibis kind of snuck this bike onto their site without much information, but we have a general idea of what’s coming thanks to the video above. In it, Ibis partner and CEO Hans Heim details the process that got them here, along with additional commentary by their Development Engineer Preston Sandusky and Engineering Manager Colin Hughe.

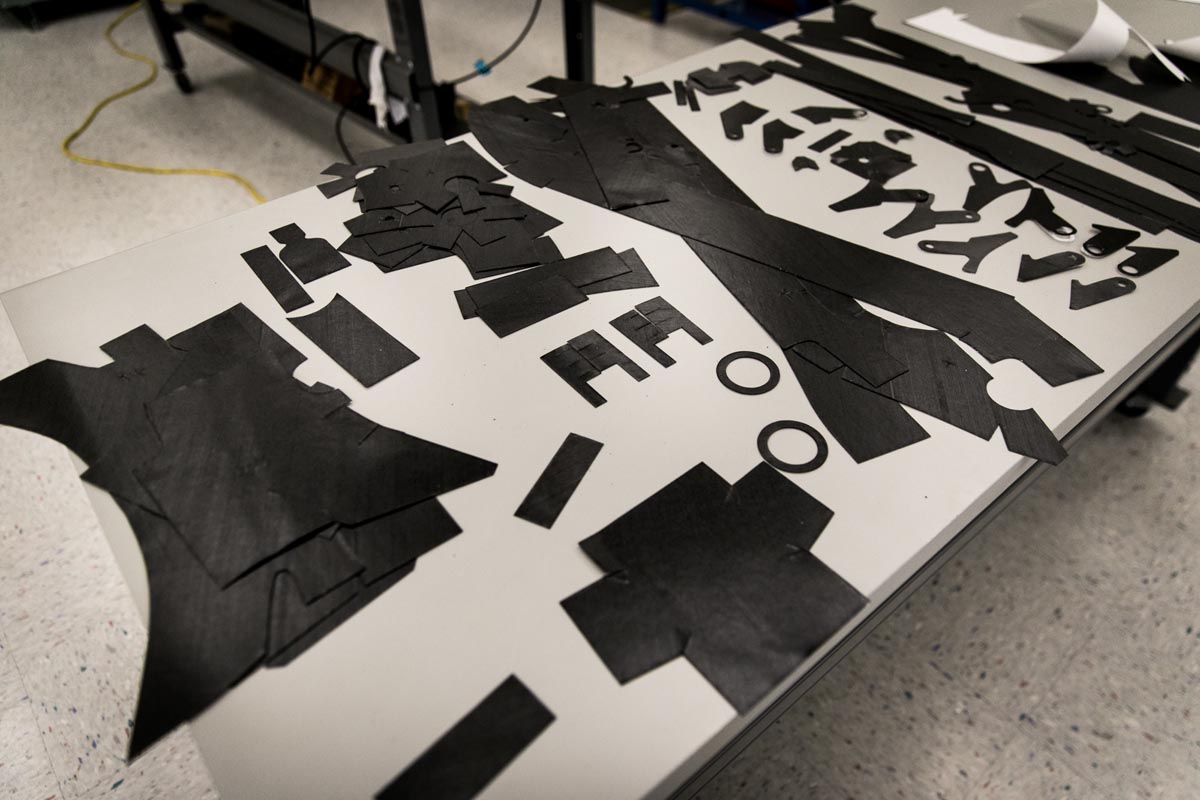

Remaining true to their claims with the initial Carbon 831 project, Ibis says two main things really set their process apart from Asian carbon factories like those that make other Ibis models in Taiwan and Vietnam: the layup and the molds.

While other factories certainly have automated cutters, Ibis claims that they use them differently. Instead of making many smaller pieces that require a lot of time to lay by hand, Ibis makes fewer, more complicated and intricate pieces that reduce the parts count from 300-400 pieces, down to about 100-120. That saves time both prepping the materials and in the layup process, which helps cut the overall time needed to make a frame substantially (the claim is roughly 40%).

Ibis also points out that the molds are internally heated which makes them more energy efficient – enough so that they can power the process with their own solar panels on the factory roof. All of this results in fewer hours spent building each frame, and less energy used to manufacture them, all while offsetting the energy needed to build the frames through renewable sources.

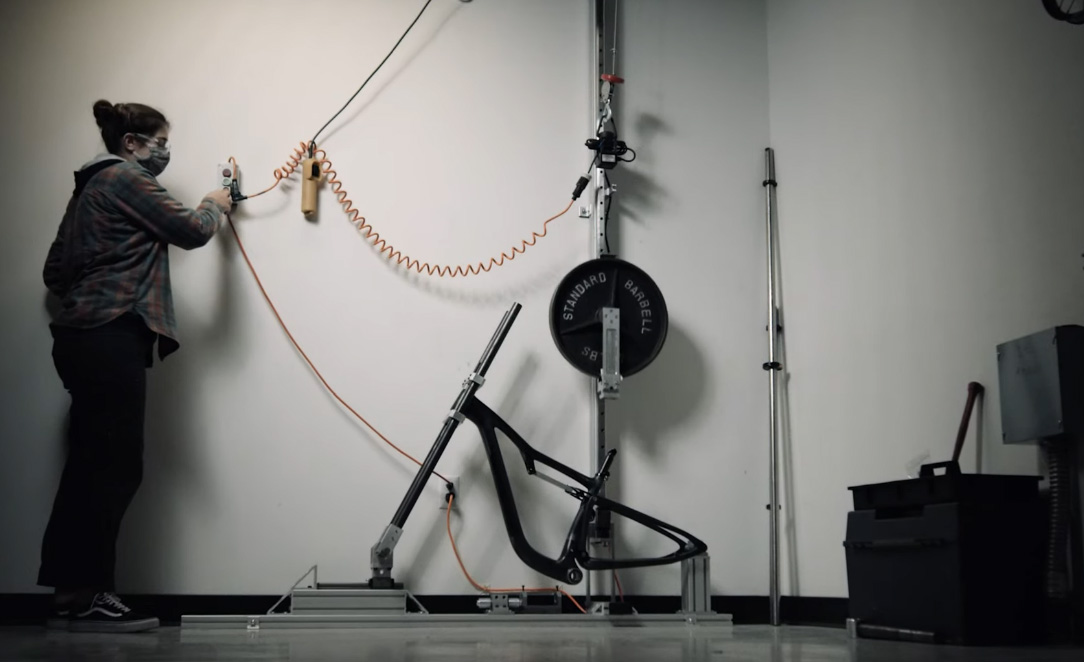

Hans goes on to say that they’ve invested in their own testing facility so that they can go back and forth between prototyping and testing quickly. That has given them the opportunity to do more iterations of each prototype, making lighter and stronger parts.

If you’re wondering why more companies haven’t gone down this route already, the answer is simple: it’s really, really hard. Hans mentions that the project has increased their respect for their factories and made them how good they really are. But that doesn’t mean there isn’t room for improvement. It’s just that that improvement doesn’t come easy.

2022 Ibis Exie Details

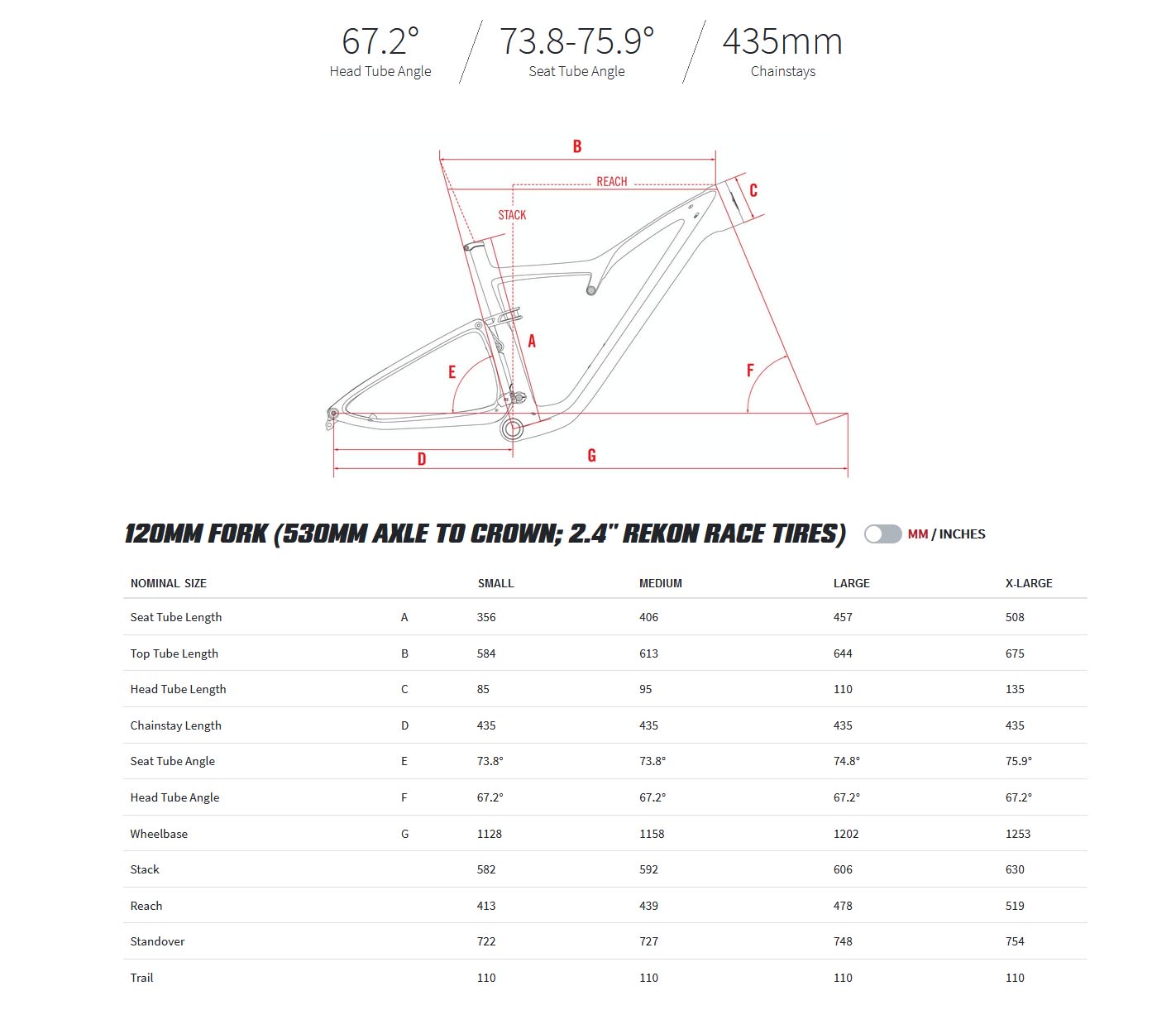

When it comes to the bike itself, Ibis hasn’t unveiled the completed bike, but we know the general layout. Designed around 29″ wheels with clearance for 2.4″ tires, the bike started life as a World Cup worthy XC bike, but evolved into more of a “BC Bike Race XC bike” for all day adventures. That means a 100mm travel frame paired with a 120mm travel fork to keep things light but capable.

Suspension comes from the legendary dw-link system with bushings for the lower link and bearings for the upper. There’s also a custom top guide that’s mounted to the lower link.

A threaded bottom bracket keeps maintenance simple, and there’s a ribbed chainstay guard to keep things quiet.

Cable routing is internal with tube-in-tube construction, and there’s room for two bottle cages inside the front triangle.

Four sizes will be offered, with a 67.2° head tube angle, and a 73.8°-75.9° seat tube angle depending on the size.

Pricing & Availability

Want one? Like all bikes at the moment, the big question mark is the supply chain needed for Ibis to spec the bikes. They’re hoping to have complete bikes rolling out the door this summer. But because of the uncertainty with what will be available, when, they’re saying that builds are subject to change.

But we can tell you that pricing for complete bikes will start around $7,999 and top out somewhere around $12,799. The frame only will also be offered for $4,499 which includes a 7 year warranty on the frame and lifetime replacement for the bushings. You can sign up at the Ibis site linked below for more details as they become available.