On a chilly winter day, I got the chance to visit 7mesh’s headquarters in Squamish, British Columbia. 7mesh has been making premium cycling clothing since 2013 when the company’s founders left the skiwear brand Arcteryx to start their own business. Growing from three to 23 employees, 7mesh’s Squamish headquarters is not only the home base for operations, this is where all product design is done, prototype garments are fully constructed, and of course, field testing takes place on Squamish’s world-class MTB trails and roadways.

I met with Ian Martin, vice president of product, who showed me around 7mesh’s facilities and gave me some eye-opening insight on how incoming environmental regulations are about to shake up the outdoor clothing industry — and how 7mesh plans to keep riders comfortable in its gear.

7mesh Headquarters

Unassuming from the outside, 7mesh’s headquarters is an industrial unit with downstairs and upstairs areas. Downstairs is the lunch area, washrooms, and design/prototyping zone with computer workstations and machines that build clothing and test fabrics. Upstairs, there is an office where operational tasks get done like finance, marketing, and e-commerce.

In separate nearby units are more storage space and 7mesh’s warehouse, where online and wholesale orders from Canada are picked and processed. 7mesh’s employees can also work from home, so at times there can be a pretty small crew at its headquarters.

Rest assured, 7mesh has the essentials for bike industry staff covered; there’s an espresso machine in the lunch area and a popular local brewery (Backcountry Brewing) right across the street!

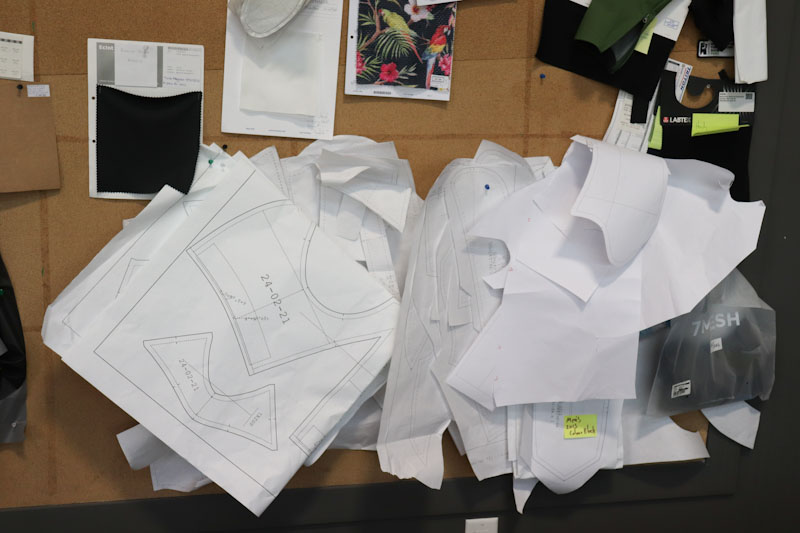

While this certainly isn’t a full-scale “factory tour” article, 7mesh basically has a mini-factory so it can construct complete prototype garments in-house. Many larger companies don’t assume such tight control over their clothes — allowing manufacturers to decide upon some design or construction details — but 7mesh doesn’t put an item into production until it’s finalized everything on its own. Designs typically begin many seasons before the products are released; 7mesh is already testing fabrics for its 2025 clothing.

The above photo shows a lengthy rack of prototypes, all of which were constructed right here. Almost all the staff at the 7mesh HQ are constantly testing prototype clothing on the local roads and trails (and do so nearly year-round due to Squamish’s typically mild winters).

Prototyping Equipment

Let’s check out some of the equipment they have on hand at 7mesh HQ, starting with this suter tester machine, which tests the waterproofing capability of seams. A sample of fabric is clamped over a rubber ring and a pump forces water from the white tank against the fabric. The pressure can be adjusted by hand as desired.

The crew at 7mesh can equate this machine’s findings to water column tests to determine how waterproof its garments really are. What’s cool to know is that 7mesh doesn’t just test brand-new fabrics, it also tests fabrics that have been through many wash cycles and samples that have been contaminated by oil.

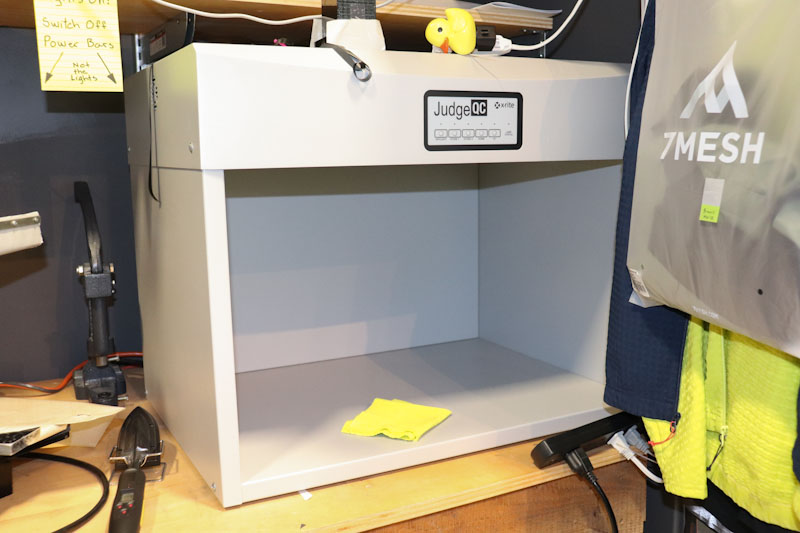

This color box replicates different light conditions and spectrums so employees can compare various fabric samples to ensure they match under all spectrums. Martin explained how one jacket uses several different fabrics and components (like zippers), so they have to ensure the different materials all look similar enough to make a uniform finished product.

7mesh’s aesthetic is on the simpler side, often with single color schemes, so it doesn’t want any clashing like glossy main fabrics against matte trim materials, for example. The color box produces more consistent results than the early techniques used by 7mesh: walking around inside and outside with samples in hand!

Next to the color box are a couple of various heat presses, which Martin says are basically fancy irons. The presses are used to laminate pockets and zippers and seal seam junctions, so they’re an essential tool for producing waterproof clothing. 7mesh also uses the presses to apply its logos.

Of course, there’s a selection of sewing machines suitable for various applications. Two of these machines get used more than the others, usually following simpler stitching techniques to bring prototypes to life.

I didn’t expect to shoot a photo when I used the washroom, but this washer and dryer are pieces of test equipment themselves. Fabric samples and garments are put through many wash cycles so the designers can see how their products will hold up to extensive use.

Beyond Squamish

Of course, not everything happens at 7mesh’s Squamish headquarters; the company sources materials from nine different countries in North America, Europe, and Asia. All manufacturing is done in southern China, and 7mesh’s biggest partner is KTC Group, which produces workwear, sailing, skiing, cycling, and other outdoor products. All of the company’s manufacturing partners pass regular social and environmental audits. While 7mesh has three international warehouses and sells its gear in 17 different countries, most of its business still comes from within Western Canada.

The Future of PFAS-Free Outdoor Clothing

When I started talking with Martin, he began telling me about PFAS chemicals, and why the entire outdoor clothing industry will soon be unable to use them. While I went with the intention of simply touring 7mesh’s facility, I suddenly realized Martin was giving me the scoop on a major shift in the industry. Here’s the story on PFAS chemicals and why outdoor clothing brands will soon have to find alternatives.

PFAS chemicals are part of the larger category of PFCs, and they are used in all kinds of products like car tires, carpets, smartphone screens, industrial plastics, ski wax, and waterproof outerwear. PFAS chemicals aid in oil contamination resistance, which is key to making waterproof clothing.

Despite being relatively small contributors to the problem, the U.S. government has decided to target ski waxes and outdoor clothing with incoming regulations. While PFAS chemicals are inert, they have been dubbed “forever chemicals” as they don’t easily break down, so potential effects from accumulation are the concern. How bad is the accumulation? Apparently, 99% of humans have PFAS chemicals in their blood.

Most states in the U.S. are expected to have PFAS bans in place by 2025 or 2026, but many clothing brands have already started moving away from them. The most concerning part for consumers is simply the performance of PFAS-free garments … which currently doesn’t match the waterproofing capabilities of clothing made with PFAS chemicals.

“Fundamentally, across the board, you just won’t see the same performance that we saw before,” said Martin. But the good news is, many brands are already getting better at making the best PFAS-free fabrics they can.

“A lot of them are out there already. There are numerous different PFC-free DWRs being tested … just now we’re starting to see that chemistry become pretty good without PFCs,” explained Martin.

7mesh has been working to eliminate PFAS chemicals from both its finished clothes and all production processes for a while now.

“We’ve had to audit our complete supply chain to make sure we’re eliminating these chemicals from it, and that we know what’s in everything we make,” Martin said.

The company has already developed a new suite of PFC-free fabrics that will debut this fall with a new clothing line, and it aims to be completely PFAS-free by 2024.

Every brand will have to adapt to using PFAS-free fabrics (the iconic GORE-TEX membrane will have to change, for one), and time will tell what methods it comes up with. Outdoor enthusiasts can only hope for some breakthrough ideas that will allow the next generation of clothing to match or outperform the PFAS-treated garments that kept us dry in the past.