We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. This time it’s all about clutch derailleur mechanisms! Hit the link at the bottom of the post to submit your own question.

If you’ve a 1x drivetrain on your mountain bike it’s highly likely the rear mech features a clutch mechanism. A what now? You may not have even noticed it, especially if your bike runs a SRAM groupset. On others, like Shimano and MicroSHIFT rear derailleurs it is more noticeable. What does it do? How does it work? And, do you really need one? We asked the experts at MicroSHIFT these questions and more.

Q&A: Clutch Derailleur Mechanisms

How does a clutch rear mech work? Basic and technical explanations welcome!

MicroSHIFT: The basic explanation is that the clutch resists movement in the tension pulley of the derailleur (the bottom pulley). If that pulley doesn’t move back and forth as much, the chain tension will stay more uniform over rough terrain and the chain will stay on the bike better. We’ve got a basic explanation video that shows all of this in action.

The technical side of things comes into play when you start to look at how the clutch internals work. You want constant tension on the chain, so you don’t want to slow the tension pulley as it exerts force toward the back of the bike to keep the chain tight. You do want to resist the pulley moving forward, so you need a way of providing friction in only one direction.

Different companies use different solutions. Most have a tension sleeve that wraps around a one-way bearing that’s attached to the cage of the derailleur. The one-way bearing allows the cage to move freely toward the back of the bike, but it engages the tension sleeve as the cage moves toward the front of the bike. As the tension sleeve stretches out, the clutch force weakens, and the clutch needs to be adjusted.

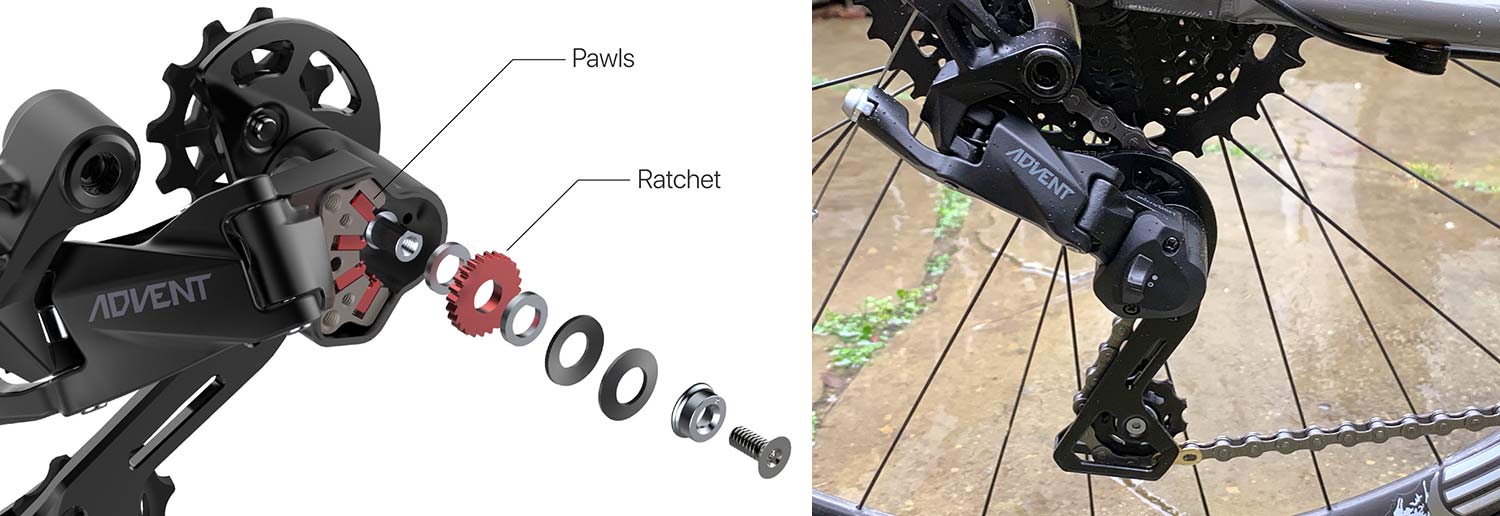

The clutch in our ADVENT and ADVENT X derailleurs is a little different. We wanted a system that didn’t lose clutch force quickly, and was extremely easy to adjust if needed. Instead of a one-way roller bearing, we use a ratchet and pawl system much like in the cassette body of a hub.

The ratchet and pawl are attached to a pair of friction washers under side-load, similar to the systems used in a coaster brake. These friction washers don’t stretch like a tension sleeve, so the clutch force stays consistent over a longer interval. To adjust tension, you just need to remove the clutch cover and turn the Torx bolt on the side, which takes about 30 seconds to complete.

Are there any disadvantages to running a clutch derailleur?

MicroSHIFT: Since the clutch resists movement in the tension pulley, it does increase the shifting force needed to change to a larger cog / easier gear. This can be minimized through derailleur geometry, but every derailleur will have an easier shifting action with the clutch off vs. having it engaged. Still, this difference won’t be noticeable to most people and the clutch is so useful for 1x drivetrains that the benefits vastly outweigh this minor negative.

Can I service the clutch on my rear mech?

MicroSHIFT: We designed ADVENT and ADVENT X derailleurs to be incredibly easy to service. Adjustment is easy, just pull the clutch cover and give the clutch tension bolt a quarter turn in either direction. We also offer a replacement ratchet ring and pawl assembly if those parts are showing extensive wear, although the system is durable enough that we haven’t sold many.

Does a clutch derailleur introduce drag into a drivetrain?

MicroSHIFT: Having a clutch that’s too strong can resist movement in some rear suspension designs, but in terms of pedaling it doesn’t create any perceptible drag. Anyone who tells you it does probably has some bearings to sell.

If I downshift into my gear of choice, rather than upshift into it, does this affect how easy it is to pedal? I’ve the feeling this has something to do with the clutch on my rear mech, but I don’t understand the mechanics of it. Can someone please explain this phenomenon?

MicroSHIFT: Shifting to a larger cog that’s easier to pedal can take a bit more force with a clutch derailleur, but if you have everything set up properly that difference shouldn’t be too noticeable. 1x systems with a clutch (especially 12-speed systems with tight tolerances) tend to need a pretty specific setup in terms of chain length and B-limit adjustment, so I would double check that everything is set up precisely to the manufacturer’s spec.

Is a clutch derailleur still necessary now we have quality narrow wide chainrings and chain guides?

MicroSHIFT: You can absolutely run a non-clutch derailleur with a guide, people did that for years! The trouble is that the chain will still bounce around like crazy over rough terrain, causing chain slap and imprecise shifting.

With a clutch, you don’t need a guide unless you’re riding technical terrain at super high speed, and shifting will be more predictable because it keeps the chain closer to the right place so that it can move from cog to cog without trouble.

Does a clutch derailleur interfere with a bike’s rear suspension?

MicroSHIFT: It depends on the design, but yes, it can have a noticeable effect. The biggest factor is how the distance between the rear axle and the bottom bracket changes as the bike goes through its travel.

The tension pulley needs to move forward as the rear center distance grows, and the clutch will resist that motion. It’s another reason why ease of adjustability was important in our design process – it can take a couple tries to get your clutch tension in the perfect spot where it’s not messing with your suspension, but also isn’t dropping the chain.

Thank you to Gus Juffer from MicroSHIFT for contributing to this week’s Ask A Stupid Question!

Got a question of your own? Click here to use the AASQ form to submit questions on any cycling-related topic of your choice, and we’ll get the experts to answer them for you!