We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. Hit the link at the bottom of the post to submit your own question.

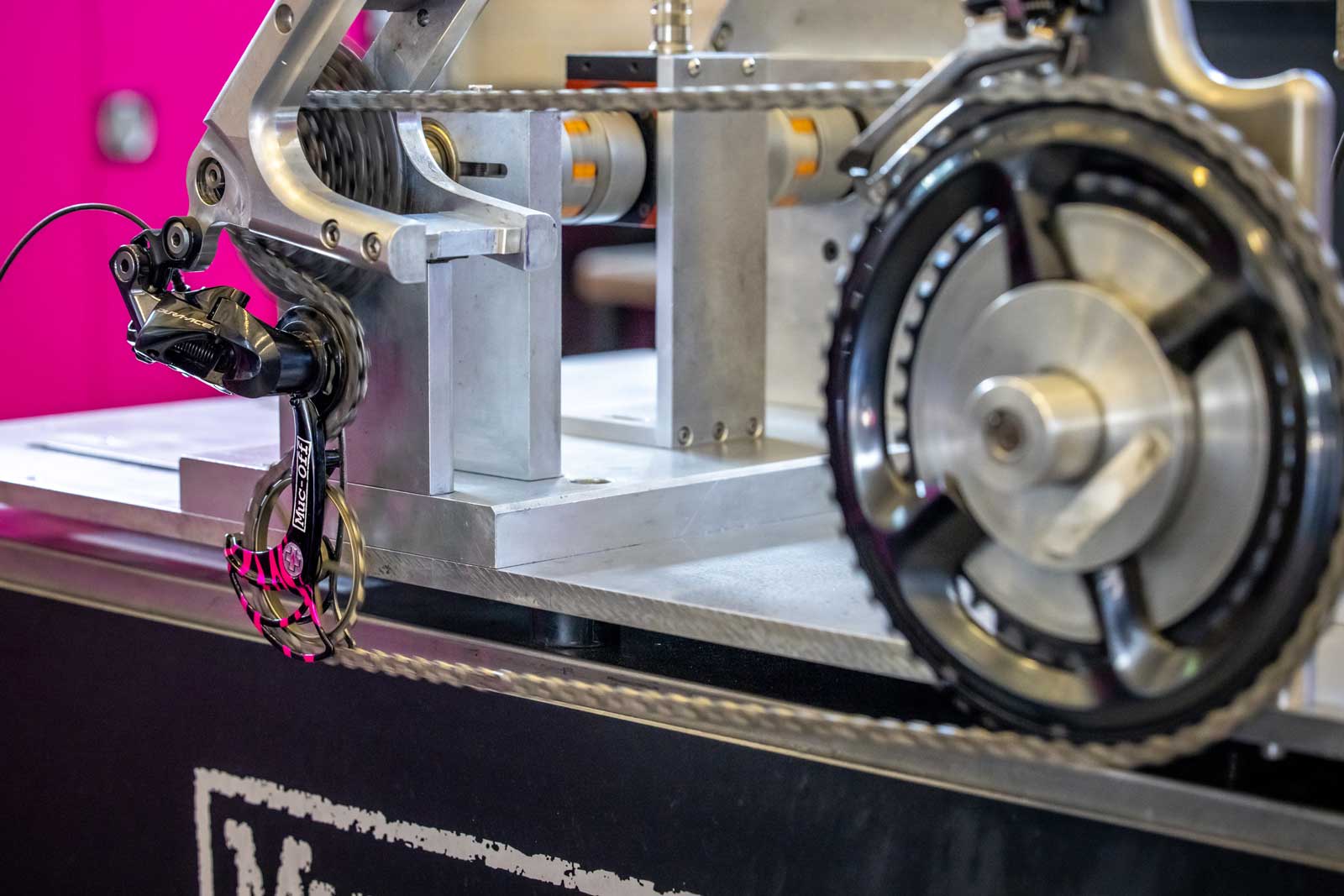

Welcome back to the Bikerumor Ask A Stupid Question series. This week, we’re joined by Kogel Bearings, Muc-Off, absoluteBLACK and CeramicSpeed to discuss the topic of oversize derailleur pulleys and cages. What are the advantages, how big is too big, and what cycling disciplines are they most suited to? Your expert contributors are as follows:

- Ard Kessels, Founder and Owner of Kogel Bearings

- Bruno Nascimento, International Sales and Marketing at absoluteBLACK

- Steve Fearn, Global Cycling PR & Comms Manager at Muc-Off

- Paul Sollenberger, Product Manager at CeramicSpeed

What are the advantages, if any, of running oversized derailleur cages and pulleys?

Kogel: The main goal for an oversized derailleur cage is to reduce drivetrain friction. Larger wheels require the chain to articulate less. Bending a chain causes friction between the plates. By making the wheels larger the chain needs to bend less every time it runs through the derailleur. Additionally, friction is reduced by using high quality bearings, and low contact seals. And lastly, a large wheel will have a lower rotating speed than a small wheel at a fixed chain speed. Although the effect of that last one is minimal.

Muc-Off: The larger the pulley wheel diameter over stock allows the chain articulation angle to be reduced, resulting in a reduction of friction as the chain articulation angle has a direct impact on power loss. Work due to friction is dependent on the articulation angle (sliding distance) the larger the articulation angle, the larger the sliding distance hence the larger the work done (higher power loss).

Being able to design and manufacture pulley wheels allows you to specify geometric details. These include aspects such as efficient tooth profiles and also specific materials and coatings for the wheels that reduce friction and increase performance.

Bearings can be optimised for the specific oversize application giving scope to reduce frictional losses not considered in standard bearings.

absoluteBLACK: The simple answer is power saving in the drivetrain. Most cyclists are familiar with the wattage savings that are possible to achieve with different chain lubricants. However, the lesser known things are the savings (and their principles) possible to achieve on the derailleur cage itself despite the fact that it is an “unloaded” part of the chain.

Many cyclists are led to believe that “free spinning pulley bearings” are the source of most gains/savings in oversized pulley wheel cages but unfortunately that is not accurate. Free spinning without load is not relevant. What matters is how the bearings operate under real load conditions. Or, in other words, what is their coefficient of friction under the load of the chain.

Moreover, bearing friction represents only a very small portion of overall savings. Meaning, both good pulley bearings consume less than 0.3W altogether. Better bearings can improve that by about 0.1W range. The measurable gains come from the cage’s spring tension preload modification, where up to 1.2W can be gained by changing the cage design to accommodate it.

However, the biggest saving comes from the size of the pulleys. Larger pulleys reduce the rotation angle between chain link plates around pins during the operation (on the pulleys) hence why it reduces the friction on the chain itself. Or, in other words, the chain articulates less when engaging with a larger pulley, and therefore, encounters less friction. The value of that saving is dependent on the chain lubrication that was used.

Our HOLLOWCAGE has however another very important advantage that separates us from other products of its kind. It silences the drivetrain. As it’s known, common polymer pulleys are fairly loud and aluminium pulleys are even louder as the material radiates the sound more than a polymer.

We created a new generation of pulleys, which are able to reduce the sound level by 12-14dB when compared to stock DuraAce pulleys thanks to our patent pending solution incorporating special xring rubber bands to dampen the chain impact on pulleys. This corresponds to roughly 60% of the noise reduction. Practically speaking, the cage (and by this drivetrain) becomes very silent.

An interesting fact is that over 80% of noise from a whole drivetrain comes from the top pulley engaging with the chain. Should you buy it? We were always up front saying that you should first invest in better wheels, tyres, a great chain lubricant and, for example, oval chainrings (as those upgrades will give you bigger savings all together) before you invest in an oversized pulley cage.

Our system should be purchased when you have already made other upgrades as it’s the ‘cherry on top of the cake’ of the upgrades you can make. It would be the final step in drivetrain optimization which all together can provide you over 10 Watts of “free” power that is simply saved (not gained) by reducing the frictional losses in your drivetrain.

CeramicSpeed: CeramicSpeed initially began development of our OSPW, or oversized pulley wheel system, to answer the question, ‘what could be done to further improve the efficiency of a drivetrain?’. Looking beyond a direct replacement of the pulley wheel bearings, we spent over 2 years of lab and field testing to validate the efficiency benefits possible by increasing pulley wheel sizes and modifying derailleur cage spring tension. Through this study, we identified three pieces that directly affect drivetrain and derailleur drag.

First, and most obvious, is the size of the pulley wheel and its effect on chain articulation. As the chain moves through the derailleur cage, there are 4 points of chain articulation in which the chain plates and rollers slide against each other. While individually not a large consumption of energy, this compounds quickly during riding to the tune of more than 10,000 articulation movements at the derailleur pulleys per minute (95RPM, 53T chainring).

The second area of friction impact is the overall speed of the pulley when and associated bearing. Pulley wheels have the fastest spinning bearings on a bike, to the tune of 4-5X your crank RPM. The easiest method of increasing the efficiency of a bearing is to reduce its speed, and larger pulleys can do this between 15-50% depending on final pulley size.

The third primary impact comes not from the pulleys or their size, but rather the cage design and spring tension settings. Modern derailleurs rely on backward spring tension to accommodate the range of chain length necessary for your largest tooth count and smallest tooth count options in gearing setup. Factory derailleurs are designed to function reliably in a vast array of conditions, resulting in specifications that aim to be ‘one size fits most/all’.

As the derailleur system is neutral from pedaling forces, chain tension and drag through the derailleur is a constant force that can be safely reduced for riders on moderate to smooth terrain. With our carefully designed OSPW cages featuring up to 4 spring tension settings, we can offer riders the ability to customize their cage tension to best suit their riding conditions and needs, without excess & unnecessary chain drag.

With these friction influences addressed, we measure over a 40% increase in drivetrain efficiency when compared to a stock derailleur arrangement. The simplest way to view this, is more of your riding output makes it from the pedals, to the rear wheel without being wasted. Additionally, some derailleur systems can also benefit from increased cassette capacities, such as a 32T cassette on a 9100 derailleur with an OSPW system, beyond the factory limitations.

Are we likely to see even bigger oversized derailleur pulleys anytime soon?

Kogel: I doubt it. Maybe someone will develop a 20 tooth wheel, just to one-up the other players on the market. We have seen this happen in mountain bike cassettes recently. The main problem that is stopping Kogel from going larger than our current wheel size is ground clearance. As wheels get larger, the derailleur cage needs to be longer, especially on road derailleurs where the upper pulley runs in line with the pivot point.

Mountain bike derailleurs have an offset upper pulley, which allows us to keep the cage length the same or even slightly shorter than the stock derailleur. There might be an opportunity to run a larger lower pulley, but that is not something we have on the drawing table right now.

Muc-Off: With larger and larger pulley wheels there are diminishing returns when considering overall efficiency. For example, there is a point where the extended length of an oversize derailleur cage may create issues in optimizing chain tension.

absoluteBLACK: Everything is possible, but it makes very little sense to go even bigger. As mentioned earlier, the bigger the pulley the smaller the rotation (bending) angle between the chain link plates around the pin when engaging the teeth. However, from 17 tooth size onward the gain becomes exponentially smaller making very little sense to go over 18-19 tooth. In addition, there is a very tight limit on the size of the top pulley to preserve great shifting because the derailleur itself is not designed to handle much more. This is why you usually see a smaller top pulley and a bigger lower pulley.

CeramicSpeed: Not likely, at least if the development is done with a focus on efficiency testing and on bike functionality. In 2013 and 2014, our initial development and testing was done in partnership with Friction Facts (prior to CeramicSpeed’s acquisition of Friction Facts in 2016) to determine the optimal pulley sizes purely for efficiency.

As tooth counts increase on pulley wheels, the diameter (and effect on chain articulation) doesn’t increase as much, resulting in less of a chain articulation, and thus friction impact. The ideal target falls around 17-19 teeth in size. Beyond just the efficiency focus, the difference in size of the stock upper pulley to a larger pulley creates a narrower window for getting the positioning and setup parameters correct and dialed on bike. This is why most systems today have mixed pulley sizes, delivering the best efficiency while achieving consistent and reliable shift quality.

Are oversized derailleur pulleys appropriate for road and off-road use?

Kogel: Absolutely, yes! All our road cages are designed with stiffness in mind to protect accurate shifting. We decided to use aluminum for our cages to make sure riders can finish a ride after a rock strike. A broken cage somewhere out in the boonies is good enough to ruin anyone’s day.

Vlad Dascalu finished second in the Snowshoe mountain bike world cup using our Kolossos oversized cage for Eagle. He ran the same cage in the Olympics and world championships. The large cogs on the cassette and tight 12 speed spacing, combined with the roots and rock gardens on course call for manufacturing precision and stiffness.

Muc-Off: For performance gains, yes, as the same engineering principles are all achievable on and off-road. Many factors, such as the specific discipline and terrain, should be considered before making a decision to go for full oversize derailleur or only ‘plus size’ pulley wheels.

absoluteBLACK: In the real world, the gains are achieved mainly in road bikes because riders pay higher attention to the drivetrain friction and cleanliness of the system. Mountain Bike derailleurs these days already enjoy bigger pulleys from stock than they used to have and the drivetrain is most times dirty with relatively high friction.

CeramicSpeed: CeramicSpeed fully approves and believes in the benefits of oversized pulleys for all disciplines of riding that involve a derailleur system and would benefit from increased pedaling efficiency. While MTB, and of course cyclo-cross, riding can feature muddy and contaminated conditions, the principles of efficiency still directly apply. Testing has even proven that the dirtier the chain is, the larger impact pulley size has on friction due to the reduced movements required of the chain.

We first introduced our OSPW X (‘X’ designation for off-road specific systems) in early 2019, and have grown to offer 6 different systems to cover nearly all modern MTB and gravel specific derailleurs. Through development and continuing today, our OSPW X systems have been tested and proven from Cape Epic, World Cup XC, and UCI World Championship Cyclo-cross races. Each system we develop fully considers the end use conditions and environment to ensure dependable performance, so much so that this year we have introduced Lifetime Warranty coverage on all OSPW and OSPW X systems.

Got a question of your own? Click here to use the Ask A Stupid Question form to submit questions on any cycling-related topic of your choice, and we’ll get the experts to answer them for you!