Ever run into a situation where the chain didn’t shift well, but your chain checker said the chain wasn’t worn out? If you’re running a modern 1x drivetrain, Abbey Bike Tools says that there is a good chance that lateral, not linear, wear is the culprit.

As 1x drivetrains have taken over and cassettes have gotten wider, that has forced riders to essentially cross chain at the extremes of the cassette. The angle of the chain then causes extra wear to the faces of the rollers which degrades the shifting over time. According to Abbey, “Depending on conditions and riding style this can happen well before a chain has reached replacement thresholds for linear wear, commonly referred to as stretch. While chains that have worn out laterally won’t cause undue wear to the rest of the drivetrain, shifting performance definitely suffers.”

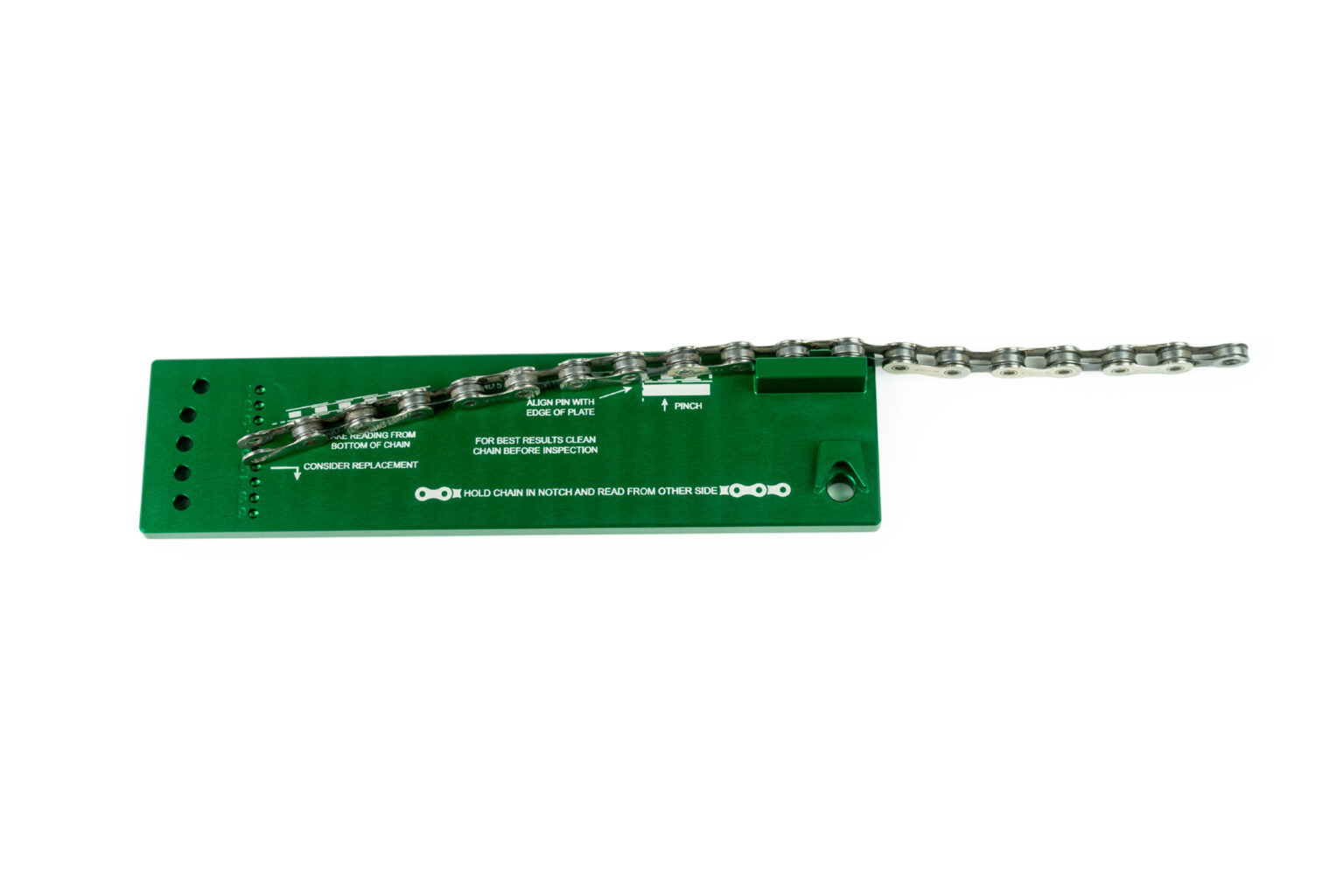

So when the precision tool maker wanted to develop their own chain wear gauge, they knew it had to include both lateral and linear measurements. That’s where the new Abbel LL Chain Wear Tool comes in. The precision tool is machined from a single block of 6061 aluminum in their CNC mill. That allows for tolerances as tight as 0.00025″ which will impact chainwear measurements by 0.004%. Compared to chain wear measurement tools that are manufactured with CNC laser cutters, Abbey claims the CNC milling method results in a more accurate tool.

Further accuracy on the linear chain wear side is guaranteed by a V-shaped notch that locates the roller. When SRAM introduced their Flattop chains, they included rollers that were 0.010″ (0.254mm) larger which is enough to skew the measurement on existing chain wear tools. How much? Abbey claims that when measuring five full links, a traditional chain tool would underreport wear by 0.2%, which “with modern drivetrains that’s the difference between replacing just your chain and the entire drivetrain.”

Instead, the V-notch locates the roller regardless of size in a position where the center of the pin is the true origin. Then you simply line up the pin with a hole on the other end of the tool to measure linear wear.

Lateral wear is also a simple test with instructions printed on the back of the tool. You start by placing the chain sideways on the plate with five links extended and then see how far the chain sags using the indicators on the left. While the linear wear test can be performed with the chain on the bike, the lateral wear test must be done with the chain removed.

The Abbey LL Chain Wear Tool is compatible with 1/8″ to 13spd chains, and is in stock and sells for $45.